Method for preparing loganin from cornus officinalis extract

A technology of strychnine and cornus, which is applied in the field of preparation of strychnine from the extract of cornus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Extraction of the fruit of Cornus officinalis

[0031] Pulverize 10 kg of dried cornus fruit through a 20-mesh sieve, use 50% ethanol as a solvent, and perform ultrasonic extraction with a liquid-to-material ratio of 10:1. The power of the ultrasonic wave is 300 W, and the extraction time is 60 min. Continuous extraction is performed three times, the extracts are combined, and the pressure is reduced. Concentrated and dried to obtain Cornus officinalis extract.

Embodiment 2

[0032] The preparation of embodiment 2 high-purity loganin

[0033] 1) Macroporous adsorption resin enrichment

[0034] The dogwood extract was dissolved in water and filtered to obtain a filtrate. The filtrate was wet-loaded onto HP-20 macroporous adsorption resin column, and after the sample was completely adsorbed, it was sequentially eluted with pure water, 10%, 40%, 70%, and 95% ethanol gradient to collect the eluate. The flow rate was 40 ml / min with 3 column volumes per gradient. According to the detection of thin layer and high performance liquid chromatography, the target substances are all enriched in the eluted part of 40% ethanol, and the eluted part of 40% ethanol is concentrated and dried under reduced pressure.

[0035] 2) Normal phase silica gel column separation

[0036]Take 500 g of the above dried product, dissolve it in 5000 ml of methanol, and mix the sample with normal phase silica gel (160-200 mesh); use atmospheric pressure silica gel column chromatog...

Embodiment 3

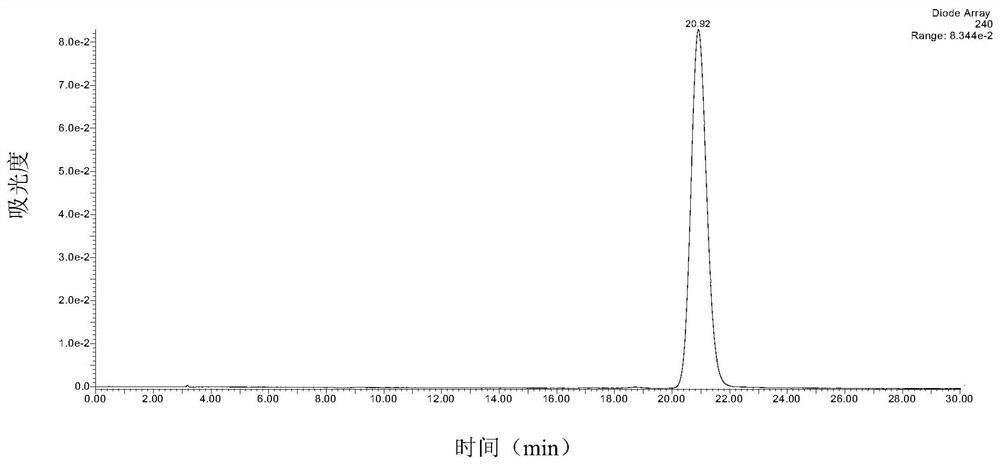

[0041] Example 3 HPLC detection method

[0042] Liquid Chromatograph: Waters 2545 Model 2998 UV Detector

[0043] Chromatographic column: Waters sunfire C18Column (4.6×250mm, 5μm)

[0044] Mobile phase: methanol: water = 30:70

[0045] Flow rate: 1mL / min

[0046] Detection wavelength: 240nm

[0047] Injection volume: 10μl

[0048] Peak time: 20.92min

[0049] Preparation solution for the test product and reference substance: dissolve in chromatographic grade methanol.

[0050] Adopt above-mentioned instrument and method, the logariside that embodiment 2 obtains is detected, logariside purity checks HPLC chromatogram such as figure 1 As shown, it was determined to be loganin monomer by comparison with the reference substance, and the purity was ≧98%.

[0051] In the present invention, the Cornus officinalis extract is preliminarily separated by macroporous adsorption resin and normal-phase silica gel, and then separated by medium-pressure reversed-phase silica gel. Conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com