Treating system for phenol tar and treating method thereof

A processing system and technology for phenol tar, applied in the processing of hydrocarbon oil, chemical instruments and methods, petroleum industry and other directions, can solve the problems of carcinogenicity, production safety and adverse effects on product quality, phenol toxicity, etc., and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

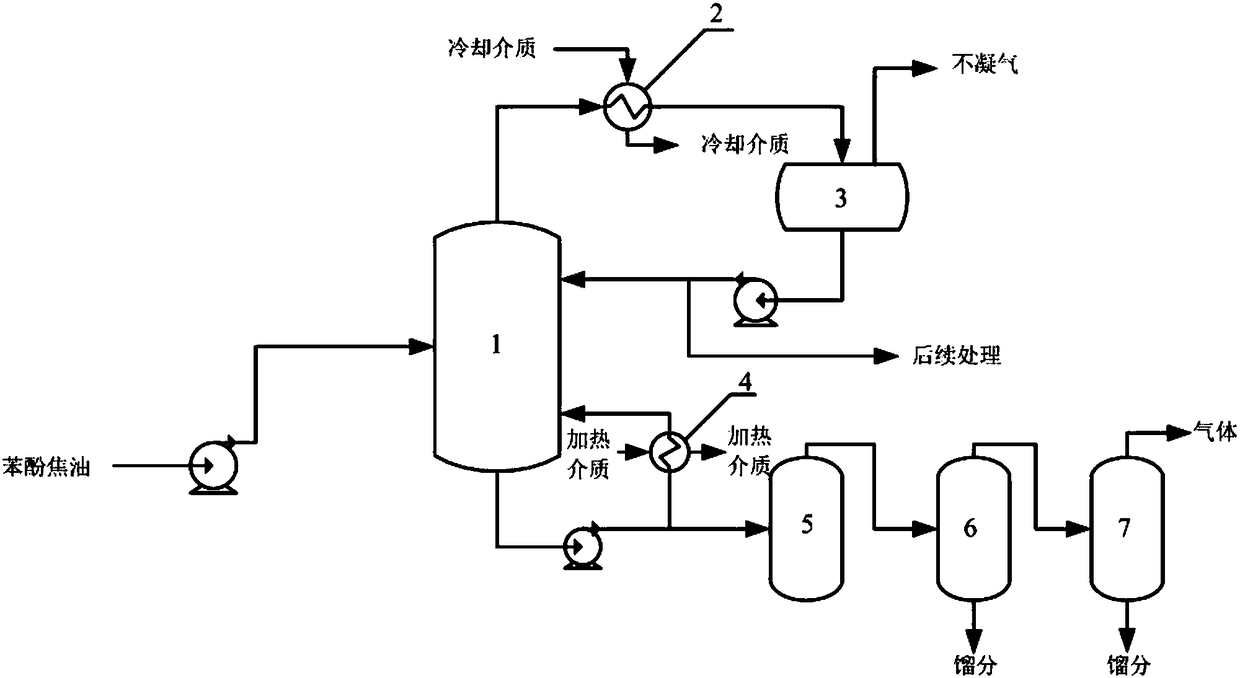

[0065] The present embodiment provides a kind of processing system of phenol tar and processing method thereof, such as figure 1 Described, described system comprises phenol cutting tower 1 and coking unit, and coking unit comprises coke tower 5, primary separation tower 6 and secondary separation tower 7 connected successively, and the tower bottom material outlet of phenol cutting tower 1 connects coke tower 5 material inlet;

[0066] Wherein, the discharge pipeline at the top of the phenol cutting tower 1 is provided with a condensing device 2 and a reflux tank 3 which are connected successively, and the outlet material of the reflux tank 3 is divided into two paths, one of which returns to the phenol cutting tower 1, and one of which is sent to a follow-up processing device; The bottom of the cutting tower 1 is provided with a reboiler 4;

[0067] In the phenol cutting tower 1, the upper part is a rectification section with 4-8 theoretical plates, and the lower part is a ...

Embodiment 2

[0077] This embodiment provides a kind of processing system and processing method of phenol tar, the structure of described system refers to the structure in embodiment 1, difference is only: the number of theoretical trays of rectifying section in phenol cutting tower 1 is 6, The number of theoretical plates in the stripping section is 16.

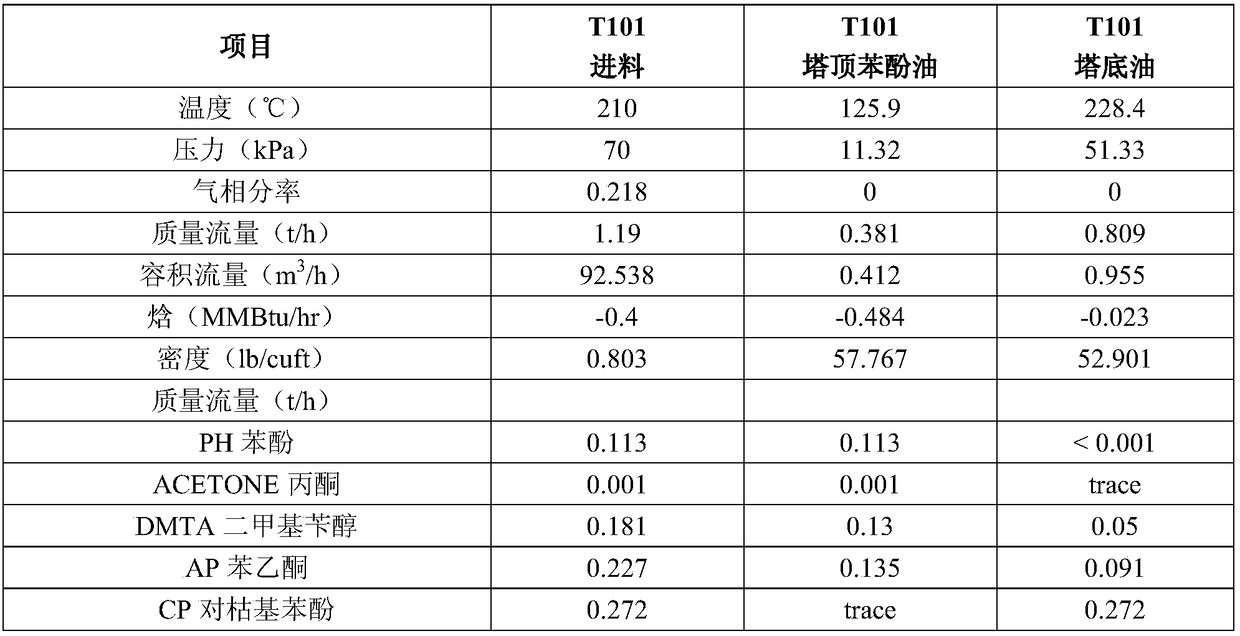

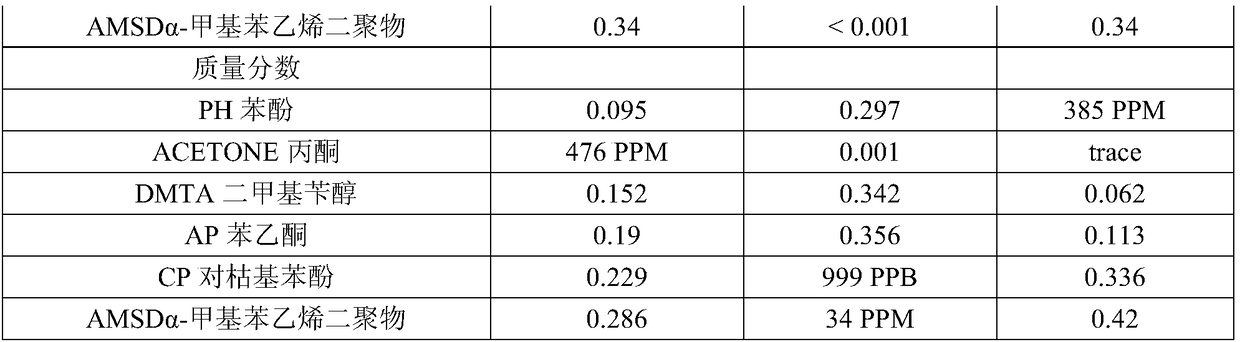

[0078] The processing method of the system refers to the method in Example 1, the difference is only that: the temperature at which phenol tar enters the phenol cutting tower 1 is 210°C; the temperature at the top of the phenol cutting tower 1 is 157°C to 159°C, and the pressure It is -31kPa~-32kPa, the temperature at the bottom of the tower is 232.4°C, and the reflux ratio of phenol at the top of the phenol cutting tower 1 is 0.12.

[0079] In this embodiment, the phenol in the phenol tar after the separation of phenol is reduced to 385 ppm, which reduces the safety risk of the subsequent phenol tar treatment, and improves the recovery r...

Embodiment 3

[0084] This embodiment provides a kind of processing system and processing method of phenol tar, the structure of described system refers to the structure in embodiment 1, difference is only: the number of theoretical trays of rectifying section in phenol cutting tower 1 is 5, The number of theoretical plates in the stripping section is 19.

[0085] The processing method of the described system refers to the method in Example 1, and the only difference is that the temperature at which phenol tar enters the phenol cutting tower 1 is 210°C; the temperature at the top of the phenol cutting tower 1 is 150°C to 152°C, and the pressure It is -26kPa~-28kPa, the temperature at the bottom of the tower is 232.4°C, and the reflux ratio of phenol at the top of the phenol cutting tower 1 is 0.33.

[0086] In this embodiment, the phenol in the phenol tar after the separation of phenol is reduced to 385 ppm, which reduces the safety risk of the subsequent phenol tar treatment, and improves t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com