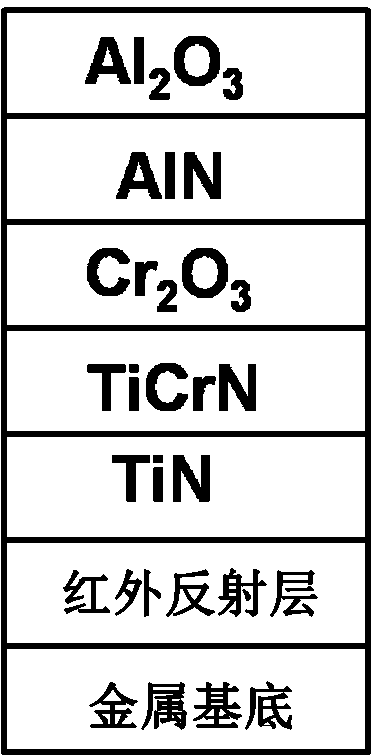

Medium-high-temperature solar selective absorbing coating and preparation method thereof

A technology for absorbing coating and solar energy, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of low thermal efficiency of coating, and achieve high absorption efficiency, low interface stress, and excellent spectral selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

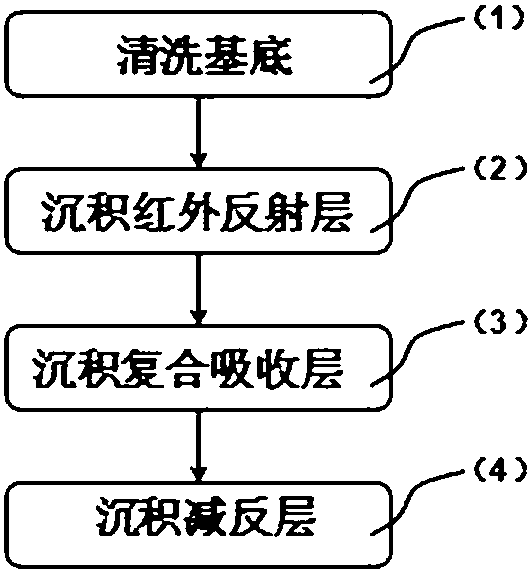

Method used

Image

Examples

Embodiment 1

[0028] (1) Select copper foil with a thickness of 0.3mm;

[0029] (2) Cleaning of the surface of the metal substrate: Put the copper foil into the ultrasonic cleaning machine, first use acetone for 20 minutes, then use alcohol for 20 minutes, and finally use deionized water for 20 minutes, and use high-pressure N 2 blow dry;

[0030] (3) Take out the copper foil and put it into the magnetron sputtering equipment to deposit the infrared reflective layer Al film. The preparation process parameters are as follows:

[0031] Target material: Al target (4N); background vacuum ≤9×10 -4 Pa; working pressure: 5×10 -1 Pa; sputtering power: 80W; sputtering process gas Ar flow rate: 30sccm; deposition thickness: 30nm, to obtain a copper foil coated with an infrared reflective layer Al film;

[0032] (4) The absorption layer TiN film is deposited in the magnetron sputtering equipment, and the preparation process parameters are as follows:

[0033] Target material: Ti target (4N); backg...

Embodiment 2

[0045] (1) Select aluminum foil with a thickness of 0.2mm;

[0046] (2) Cleaning of the surface of the metal substrate: Put the aluminum foil into the ultrasonic cleaning machine, first use acetone for 20 minutes, then use alcohol for 20 minutes, and finally use deionized water for 20 minutes, and use high-pressure N 2 blow dry;

[0047] (3) Take out the aluminum foil and put it into the magnetron sputtering equipment to deposit the infrared reflective layer Ag film. The preparation process parameters are as follows:

[0048] Target material: Ag target (4N); background vacuum ≤9×10 -4 Pa; working pressure: 5×10 -1 Pa; sputtering power: 80W; sputtering process gas Ar flow rate: 30sccm; deposition thickness: 25nm, to obtain an aluminum foil coated with an infrared reflective Ag film;

[0049] (4) The absorption layer TiN film is deposited in the magnetron sputtering equipment, and the preparation process parameters are as follows:

[0050] Target material: Ti target (4N); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com