Prefabricated flexible concrete frame joint structure with added hidden dampers

A technology of flexible concrete and node structures, which is applied to building components, building structures, protective buildings/shelters, etc., can solve the problems of viscoelastic damper performance, concrete structure damage, and occupied space, etc., to achieve Improve the self-recovery ability, improve the shear bearing capacity, and improve the effect of energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

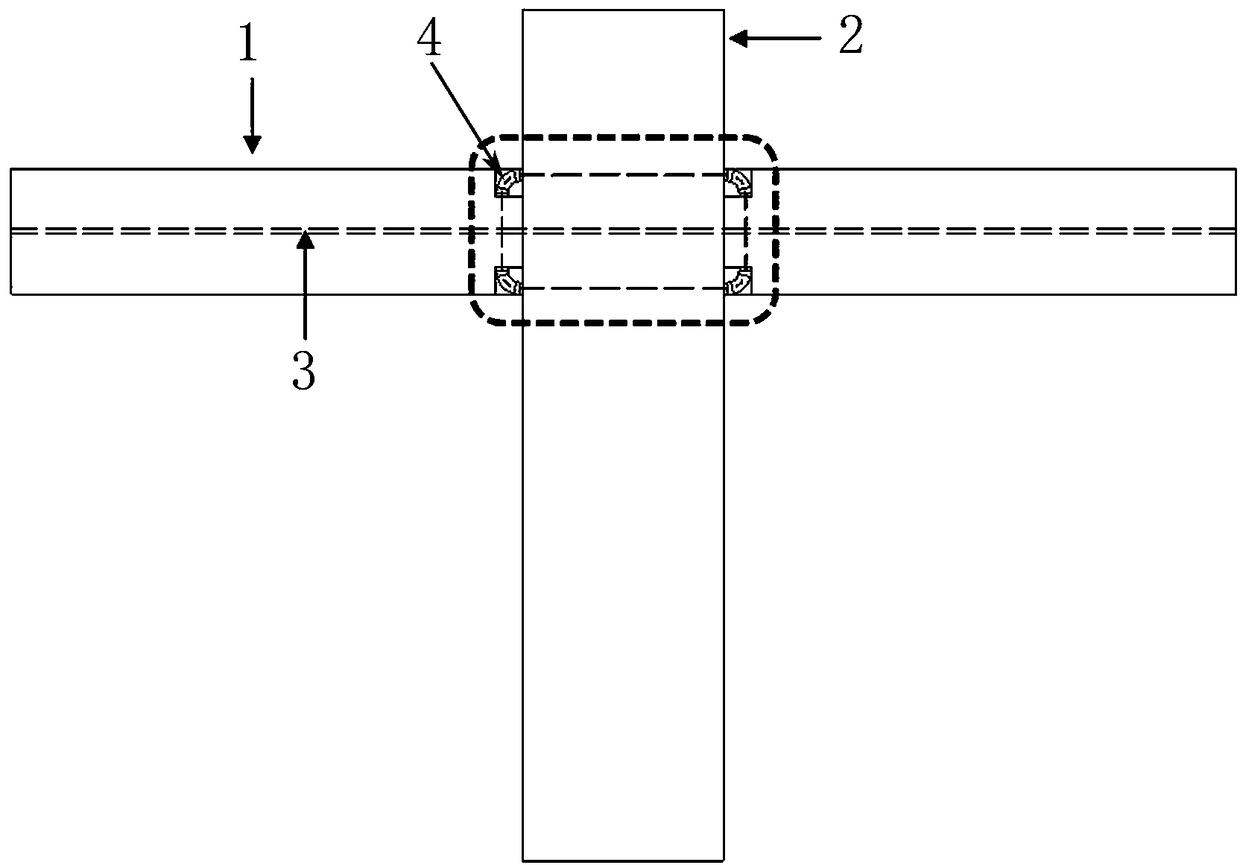

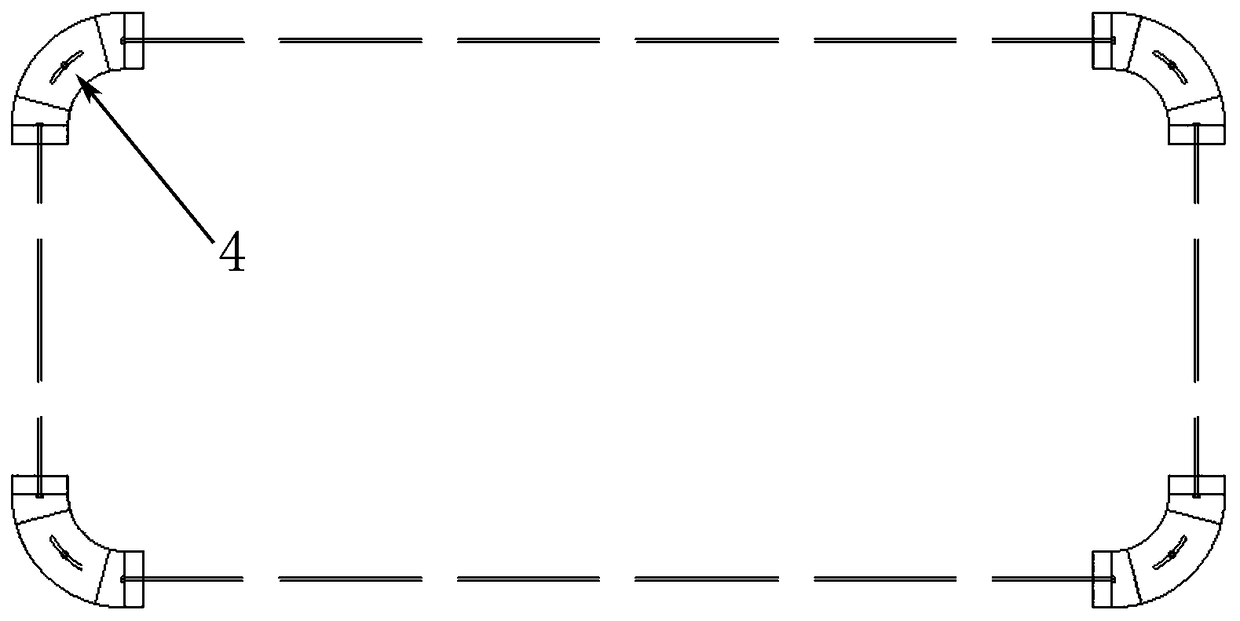

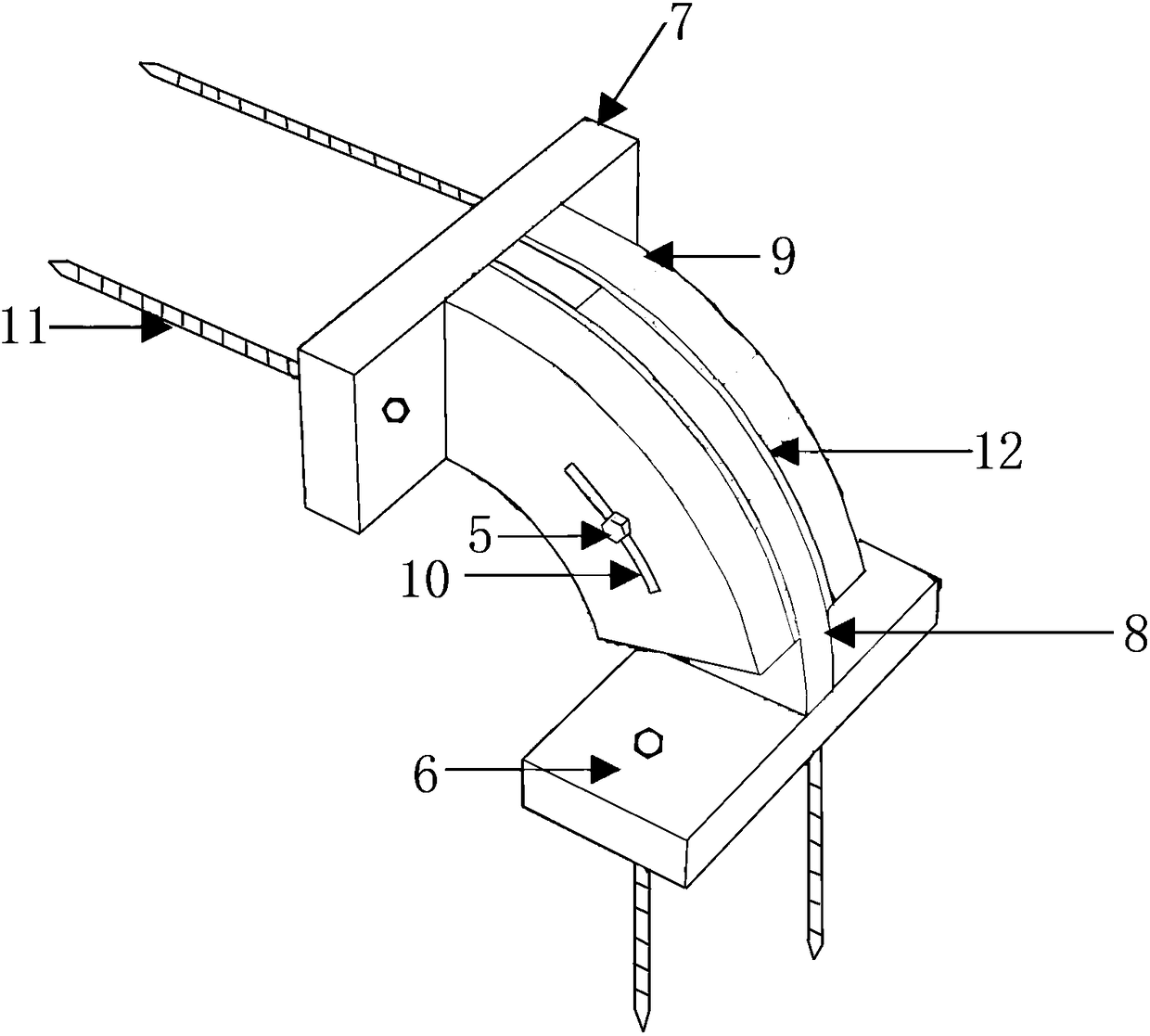

[0032] Concrete prefabricated beams with dimensions of 4000mm×450mm×700mm and concrete prefabricated columns of 700mm×700mm×3200mm are directly delivered to the site for dry assembly, such as Figure 1a As shown, the concrete prefabricated beam 1 and the concrete precast column 2 are placed flat on the ground in the shape of a "ten"; by installing high-strength bolts 11 and the positions of the bolt holes at the joints of the beams and columns, the positions of the bolt holes are arranged along the intersection of the beams and columns, and all The bolt hole is 125mm away from the beam-column intersection, and the installation specification is a damper 4 with a radius R of 115mm and a fan plate and friction plate width of 45mm, and the positioning high-strength bolt 5 is tightened, and the tightening force is about half of the design pretension; Prestressed steel strands with a specification of 9-7Φ5 are penetrated into the reserved channel of the pipe to form a flexible self-r...

Embodiment 2

[0038] Concrete prefabricated beams 1 and 1200mm×1200mm×4500mm concrete prefabricated beams 1 and 1200mm×1200mm×4500mm concrete prefabricated beams 1 with dimensions of 8000mm×650mm×1000mm are directly delivered to the site for dry assembly, such as Figure 1a As shown, the concrete prefabricated beams and concrete prefabricated columns are placed flat on the ground in the shape of a "ten"; by installing high-strength bolts 11 and positioning bolt holes at the joints of beams and columns, the bolt holes are arranged along the intersection of beams and columns, and all bolt holes 180mm away from the beam-column intersection, install a damper with R of 170mm, fan plate and friction plate width of 75mm, and tighten the positioning high-strength bolt 5, the tightening force is about half of the design pre-tensioning force; reserve a hole in the metal bellows The prestressed steel strand 3 with a specification of 12-7Φ5 is penetrated into the tunnel, so that it can be stressed as a ...

Embodiment 3

[0044] Concrete prefabricated beams 1 and 400mm×400mm×2500mm concrete prefabricated beams 1 and 400mm×400mm×2500mm concrete prefabricated columns 2 are directly delivered to the site for dry assembly, such as Figure 1a As shown, the prefabricated concrete beams and prefabricated concrete columns are placed flat on the ground in the shape of a "ten"; by installing high-strength bolts 11 and the position of the positioning bolt holes at the contact of the beams and columns, the positions of the bolt holes are arranged along the intersection of the beams and columns, and all the bolt holes The distance from the beam-column intersection is 105mm, install the damper 4 whose R is 95mm, the width of the fan plate and the friction plate is 40mm, and tighten the positioning high-strength bolt 5, and its tightening force is about half of the design pre-tension force; The prestressed steel strand 3 with a specification of 9-7Φ5 is penetrated into the tunnel, so that it can be stressed as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com