Preparation method of high-flexibility polymer solid-state electrolyte membrane and preparation method of lithium ion battery

A technology of solid electrolyte membrane and lithium-ion battery, which is applied in the field of green energy storage to achieve the effect of reducing internal friction, wide application prospects, and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

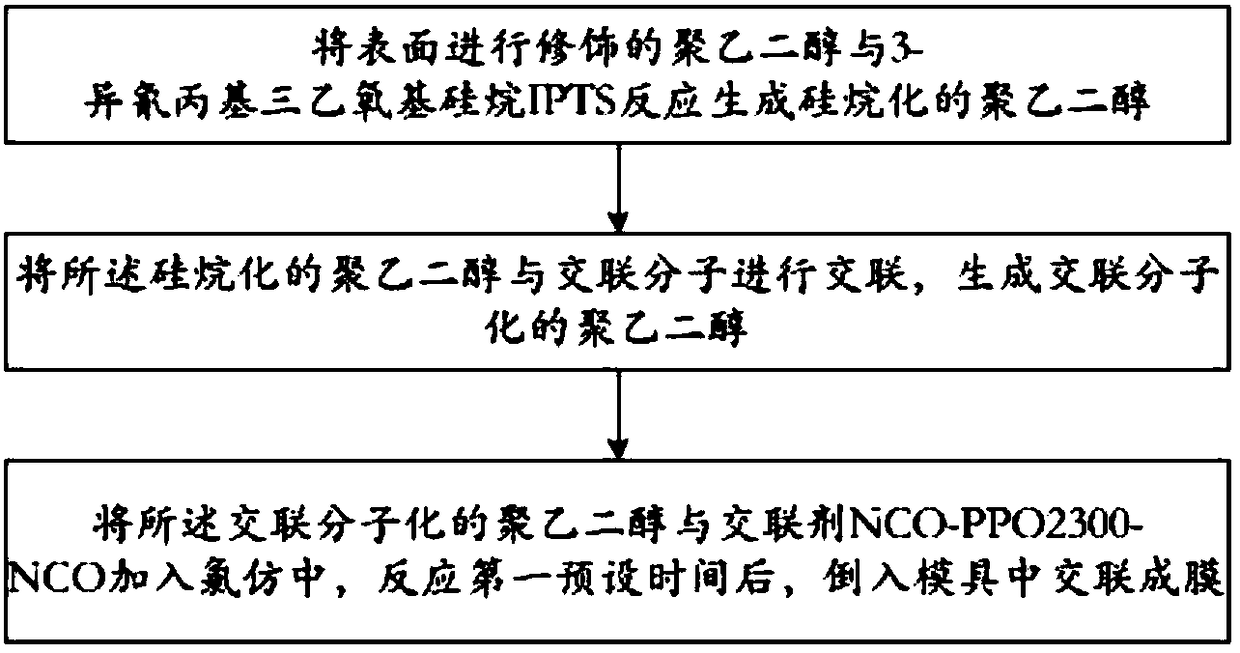

[0038] Such as figure 1 As shown, Example 1 of the present invention is a method for preparing a highly flexible polymer solid electrolyte membrane, comprising the following steps:

[0039] Step 1, reacting the surface-modified polyethylene glycol with 3-isocyanopropyltriethoxysilane IPTS to generate silanized polyethylene glycol;

[0040] Step 2, cross-linking the silanized polyethylene glycol with cross-linking molecules to generate cross-linked molecularized polyethylene glycol;

[0041] Step 3: Add the cross-linked molecularized polyethylene glycol and cross-linking agent NCO-PPO2300-NCO into chloroform, react for a first preset time, and then pour into a mold to cross-link to form a film.

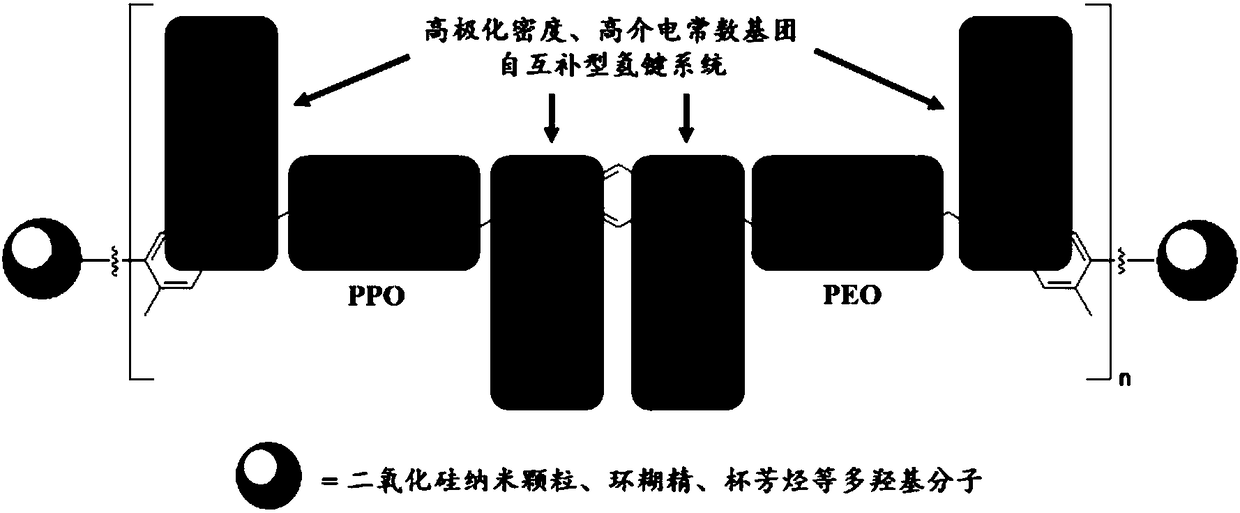

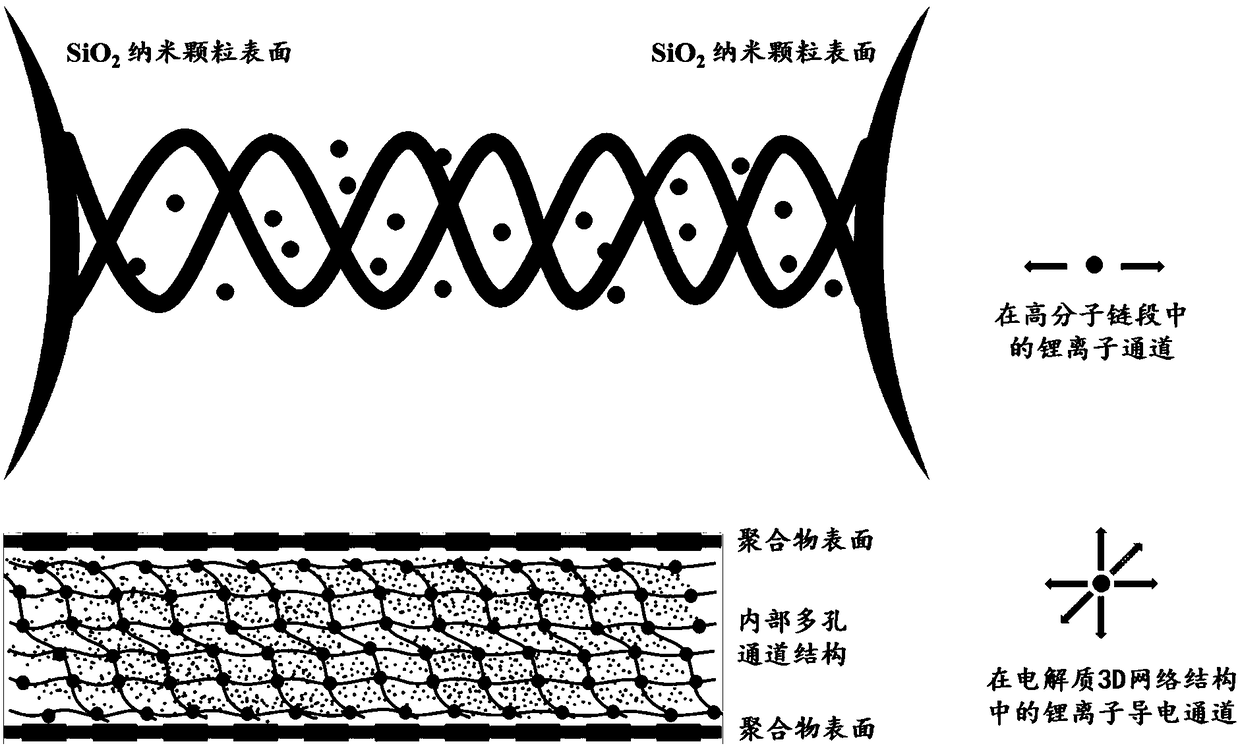

[0042] Silanized polyethylene glycol and cross-linked molecules form highly flexible supramolecular structures, such as figure 2 As shown, the polymer solid electrolyte membrane has excellent mechanical strength, and the maximum elongation at break can reach 700%. It can be made int...

Embodiment 2

[0043] Example 2 of the present invention is a method for preparing a high-flexibility polymer solid-state electrolyte membrane. On the basis of Example 1, the step 1 is specifically: dissolving the surface-modified polyethylene glycol in tetrahydrofuran THF, and sequentially Nitrogen is passed into the tetrahydrofuran THF, the catalyst dibutyltin dilaurate DBTDL is added, and 3-isocyanopropyltriethoxysilane IPTS is added to react to generate silanized polyethylene glycol.

Embodiment 3

[0044] Example 3 of the present invention is a method for preparing a highly flexible polymer solid electrolyte membrane. On the basis of Example 1 or 2, the step 2 is specifically: dissolving the silanized polyethylene glycol in deionized water , and then add cross-linking molecules to the deionized water to react to generate cross-linking molecularized polyethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com