Preparation method of rare earth upconversion composite nanomaterial, product and application

A composite nanomaterial and rare earth up-conversion technology, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, and materials for wave energy or particle radiation treatment. It can solve the problems of no PDT preparations and achieve good Biological safety, good possibility of clinical transformation, and efficient killing of tumor cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Synthesis of rare earth up-conversion nanomaterials

[0051] Add 0.5mmol sodium trifluoroacetate, 0.09mmol yttrium trifluoroacetate, 0.4mmol ytterbium trifluoroacetate and 0.01mmol erbium trifluoroacetate to the mixture of 5mmol octadecene and 5mmol oleic acid, under vacuum condition at 120°C Stir to remove water and gas for 10 minutes.

[0052] Subsequently, the reaction solution was injected into a mixture of 5 mmol octadecene and 5 mmol oleic acid at a temperature of 310° C. at a rate of 0.3 mL / min, and reacted for 1 h.

[0053] Subsequently, a mixture of 5 mmol octadecene and 5 mmol oleic acid dissolved in 2 mmol calcium trifluoroacetate was injected twice at 0.3 mL / min, reacted for 30 min, cooled to room temperature, precipitated with ethanol, and centrifuged to obtain rare earth Convert nanomaterials.

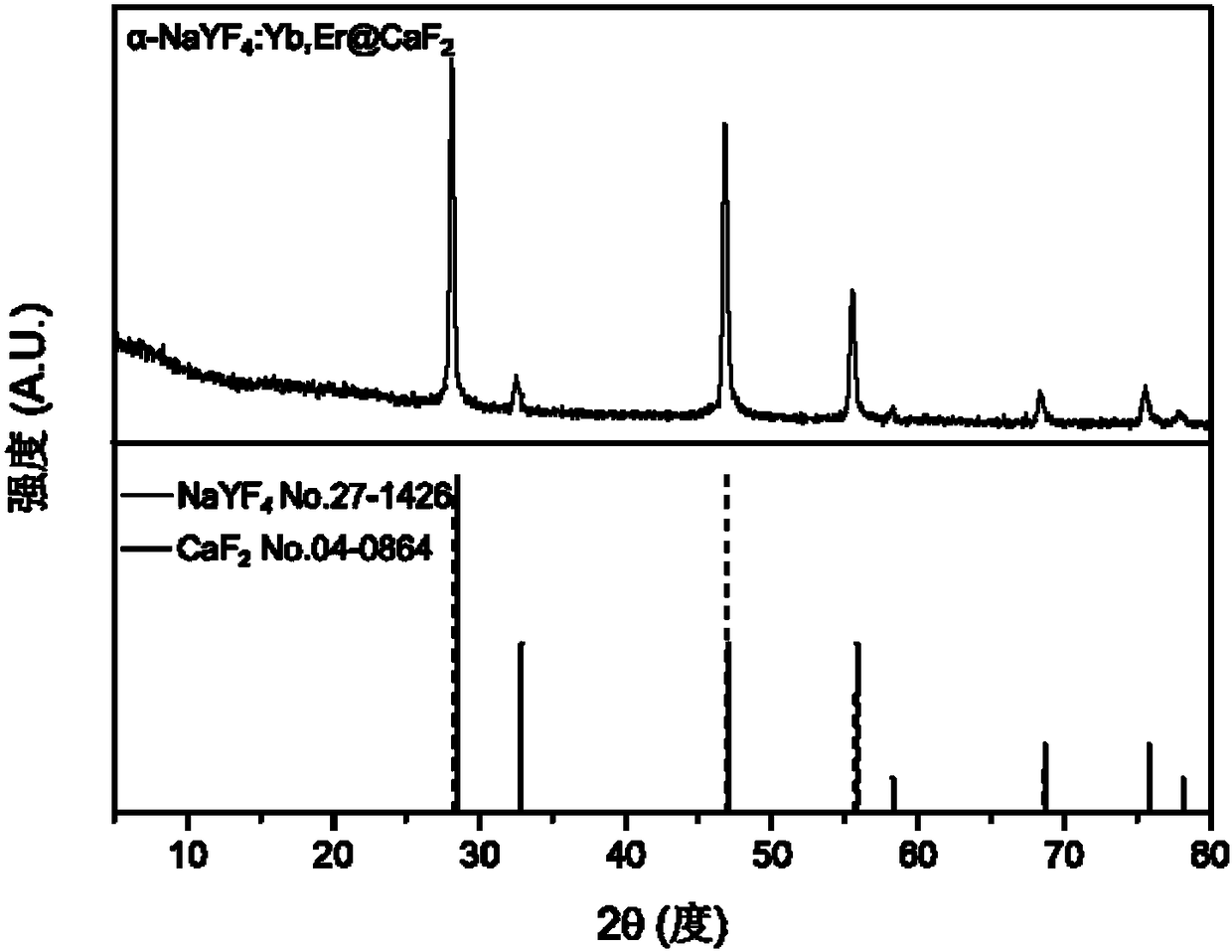

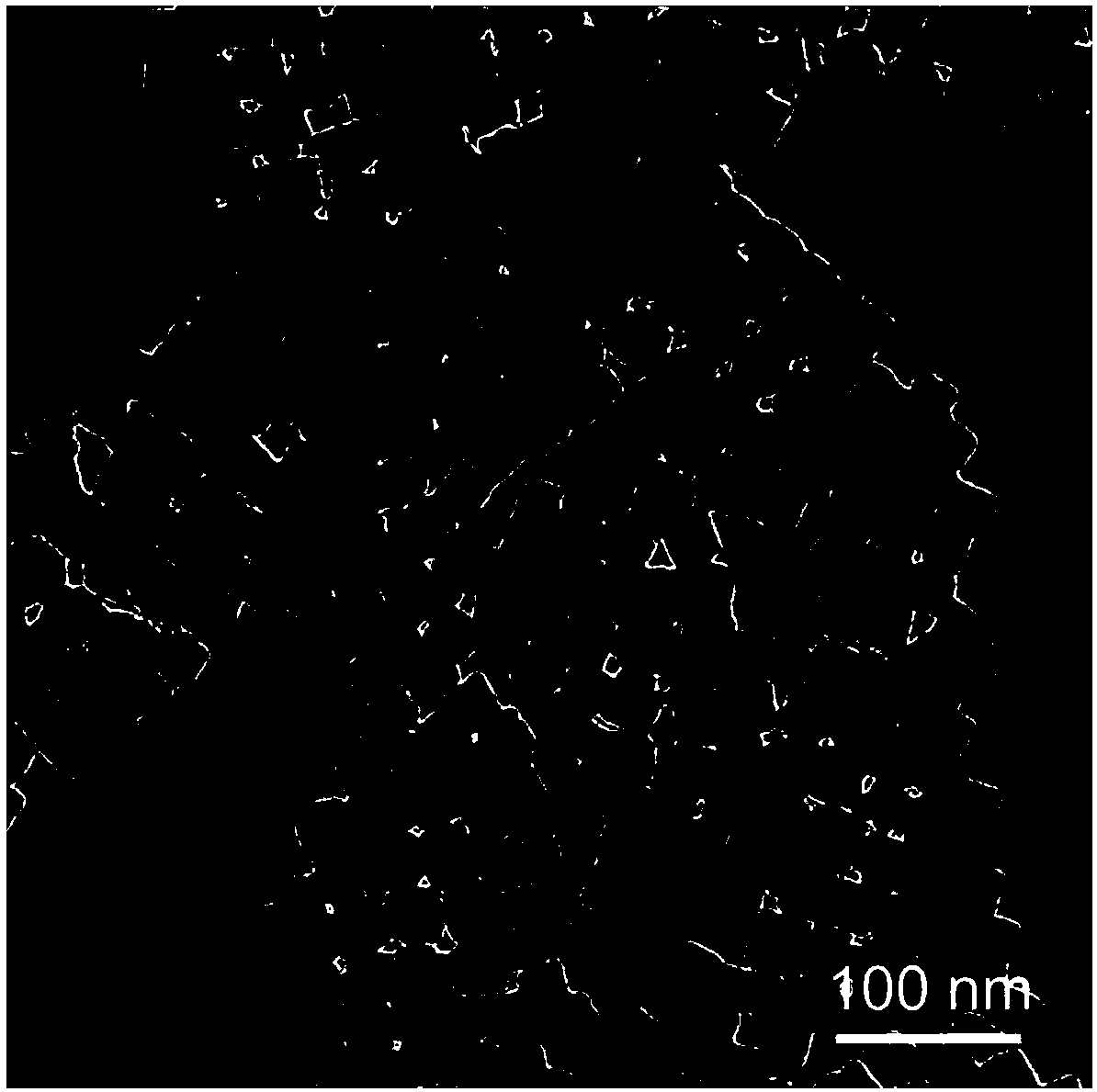

[0054] Carry out X-ray diffraction analysis to the obtained rare earth up-conversion nanomaterial, the result is as attached figure 1 shown; the r...

Embodiment 2

[0055] Embodiment 2: Synthesis of Rare Earth Upconversion Nanomaterials

[0056] Add 0.5mmol sodium trifluoroacetate, 0.39mmol yttrium trifluoroacetate, 0.1mmol ytterbium trifluoroacetate and 0.01mmol erbium trifluoroacetate to the mixture of 8mmol octadecene and 8mmol oleic acid, under vacuum condition at 110°C Stir to remove water and air for 20 minutes.

[0057] Subsequently, the reaction solution was injected at a rate of 1 mL / min into a mixture of 8 mmol octadecene and 8 mmol oleic acid at a temperature of 300° C., and reacted for 1.5 h.

[0058] Subsequently, a mixture of 8 mmol octadecene and 8 mmol oleic acid dissolved in 2 mmol calcium trifluoroacetate was injected twice at 1 mL / min, reacted for 20 min, cooled to room temperature, precipitated with ethanol, and centrifuged to obtain rare earth upconversion nanomaterials.

Embodiment 3

[0059] Embodiment 3: Synthesis of rare earth up-conversion nanomaterials

[0060] Add 0.5mmol sodium trifluoroacetate, 0.09mmol yttrium trifluoroacetate, 0.4mmol ytterbium trifluoroacetate and 0.01mmol erbium trifluoroacetate to the mixture of 5mmol octadecene and 5mmol oleic acid, under vacuum condition at 120°C Stir to remove water and gas for 10 minutes.

[0061] Subsequently, the reaction solution was injected into a mixture of 5 mmol octadecene and 5 mmol oleic acid at a temperature of 310° C. at a rate of 0.3 mL / min, reacted for 1 h, cooled to room temperature, precipitated with ethanol, and centrifuged to obtain rare earth upconversion nanomaterials.

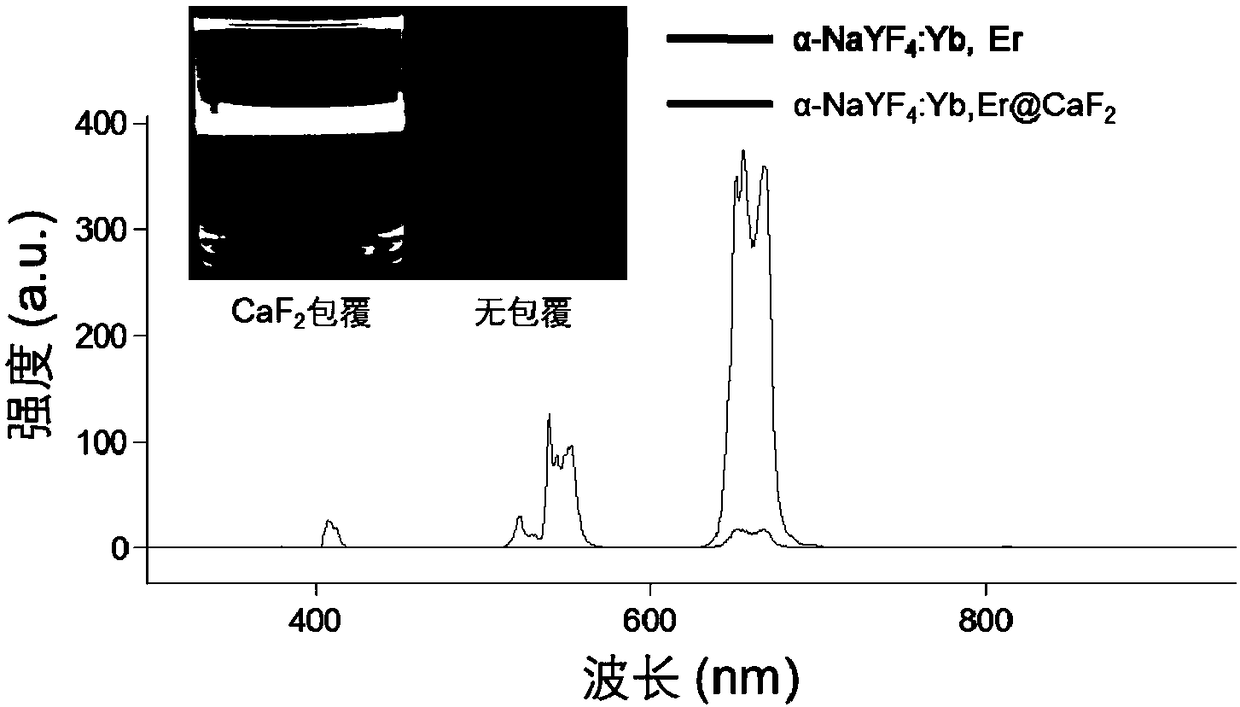

[0062] The fluorescence spectra of the rare earth up-conversion nanomaterials obtained in Examples 1 and 3 were measured at 980 nm. The result is as image 3 As shown, the luminescence intensity of rare earth up-conversion nanomaterials is significantly improved after coating with calcium fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com