A novel reverse osmosis membrane and its preparation method

A reverse osmosis membrane, a new type of technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems affecting the appearance of reverse osmosis membrane, membrane surface pollution, easy oxidation and discoloration, etc., to improve water flux and rejection rate, overcoming the mutual limitation of flux and rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

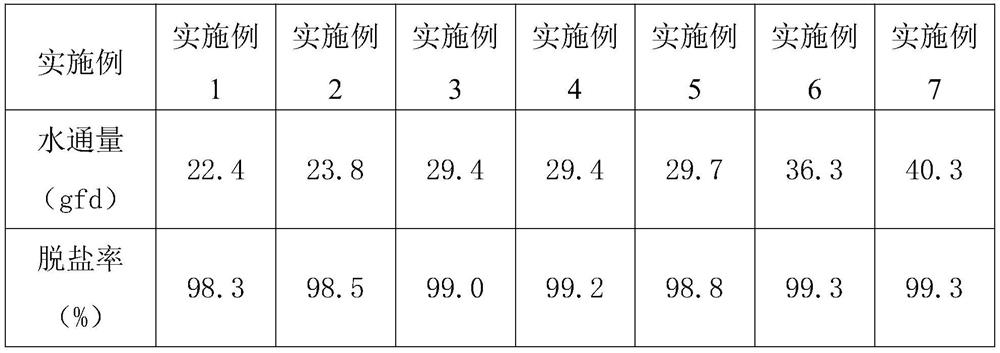

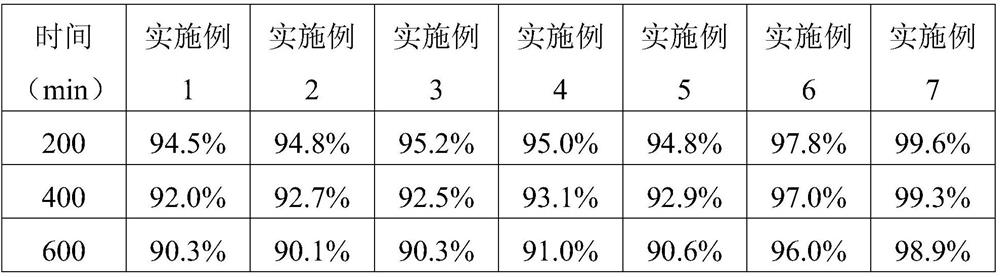

Examples

Embodiment 1

[0108] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stir at a speed of 200r / min for 24 hours to obtain solution 1;

[0109] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0110] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue stirring at the original speed until completely dissolved, and obtain solution 2; ...

Embodiment 2

[0119] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stirring at a speed of 200r / min and vacuum stirring for 24 hours to obtain solution 1;

[0120] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0121] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue stirring at the original speed until completely dissolved,...

Embodiment 3

[0130] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stirring at a speed of 200r / min and vacuum stirring for 24 hours to obtain solution 1;

[0131] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0132] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue to stir at the original speed until completely dissolved, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com