Novel reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, a new type of technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as short service life, chlorine oxidation, flux and desalination rate limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

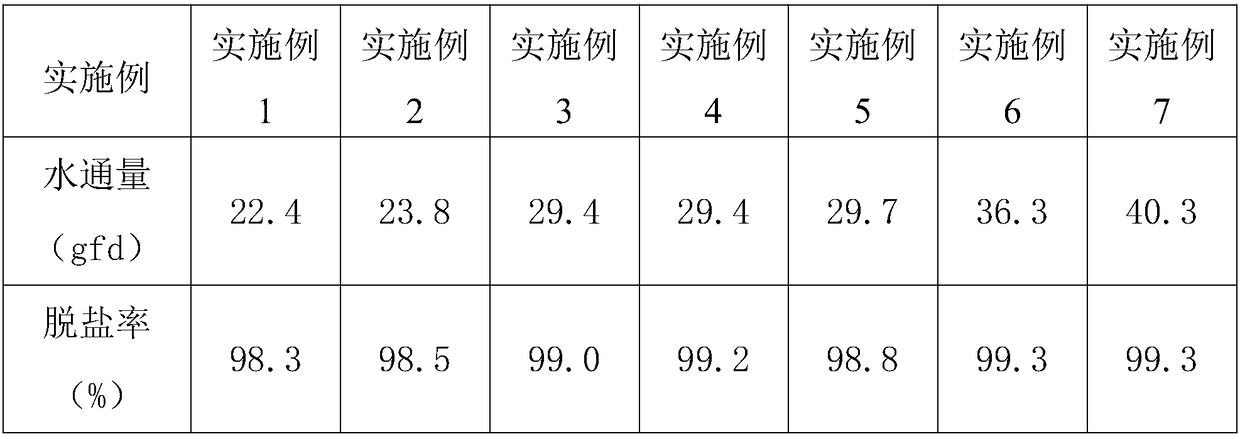

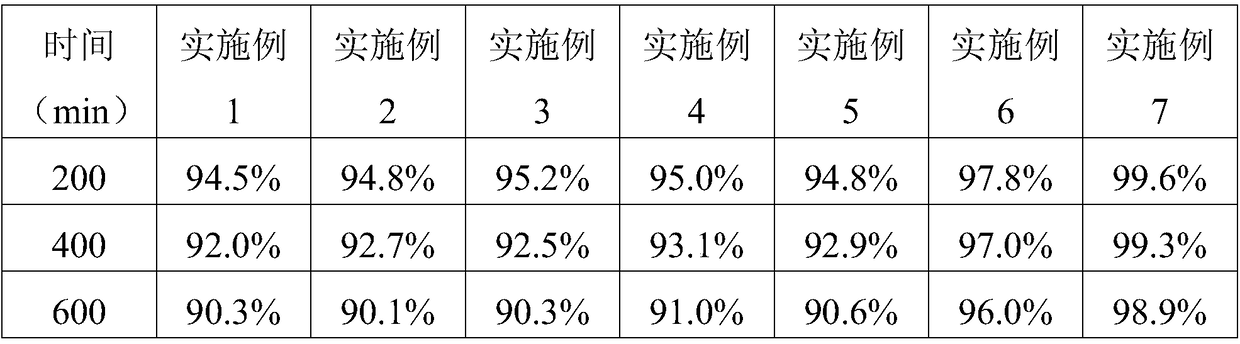

Examples

Embodiment 1

[0108] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stir at a speed of 200r / min for 24 hours to obtain solution 1;

[0109] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0110] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue stirring at the original speed until completely dissolved, and obtain solution 2; ...

Embodiment 2

[0119] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stirring at a speed of 200r / min and vacuum stirring for 24 hours to obtain solution 1;

[0120] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0121] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue stirring at the original speed until completely dissolved,...

Embodiment 3

[0130] (1) Configuration solution 1: add to the stirrer and account for each component of following mass fraction: the dimethyl sulfoxide of 75%, the polyaryl sulfone of 20% and the ethylene glycol of 5%, under the vacuum of 10mbar Stirring at a speed of 200r / min and vacuum stirring for 24 hours to obtain solution 1;

[0131] (2) Scrape coating support layer: cast solution 1 on the surface of the non-woven fabric, scrape off the solution layer on both sides of the non-woven fabric with a scraper, and then form a support on the surface of the non-woven fabric through gel phase inversion in a 10°C cold water bath layer, and then formed by pretreatment with hot water at 90°C to form a support layer with a thickness of 120 μm to obtain a film containing the support layer;

[0132] (3) Configure solution 2: add water and triethylamine to the agitator, stir evenly at a speed of 200r / min, then add m-phenylenediamine, continue to stir at the original speed until completely dissolved, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com