Preparation method of modified reverse osmosis membrane

A reverse osmosis membrane and modification technology, applied in reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve problems such as membrane pore clogging and membrane performance degradation, and achieve low manufacturing cost, simple production process, cut-off Effect of high salt rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

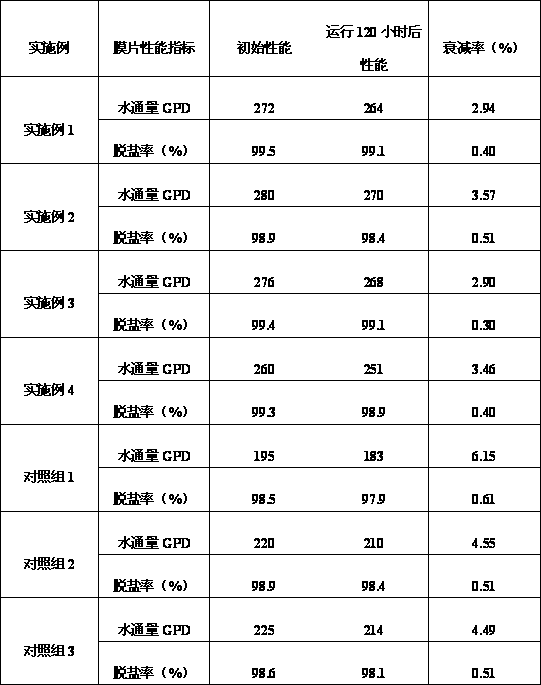

Embodiment 1

[0027] Add 1.5wt.% organic monolithic montmorillonite, 5wt.% PEO, and 18wt.% polyethersulfone to N-methylpyrrolidone, dissolve and let stand for defoaming to obtain casting solution; Apply the prepared casting solution on the non-woven fabric, immerse in water for coagulation bath after scraping the film, and prepare the reverse osmosis membrane base membrane by dipping-precipitation phase inversion method; take the base membrane and dry it vertically in the shade, and coat the surface with 2wt .% m-phenylenediamine solution, after vertical drying, then coated with 0.08wt.% trimesoyl chloride solution for interfacial polymerization reaction, poured out the solution and dried it in a 60°C oven for 10 minutes to prepare a reverse osmosis membrane; Add 0.05w / v.%SDS to the MES buffer solution as a surfactant, TEA as an acid-binding agent, adjust the pH of the solution to 4.0 with HCl, soak the prepared reverse osmosis membrane in the solution for 5h; use deionized water After rins...

Embodiment 2

[0029] Add 4.5wt.% organic monolithic montmorillonite, 5wt.% PEO, and 18wt.% polyethersulfone to N-methylpyrrolidone, dissolve and let stand for defoaming to obtain casting solution; use automatic coating Apply the prepared casting solution on the non-woven fabric, immerse in water for coagulation bath after scraping the film, and prepare the reverse osmosis membrane base membrane by dipping-precipitation phase inversion method; take the base membrane and dry it vertically in the shade, and coat the surface with 2wt .% m-phenylenediamine solution, after vertical drying, then coated with 0.08wt.% trimesoyl chloride solution for interfacial polymerization reaction, poured out the solution and dried it in a 60°C oven for 10 minutes to prepare a reverse osmosis membrane; Add 0.05w / v.%SDS to the MES buffer solution as a surfactant, TEA as an acid-binding agent, adjust the pH of the solution to 4.0 with HCl, soak the prepared reverse osmosis membrane in the solution for 5h; use deion...

Embodiment 3

[0031] Add 1.5wt.% organic monolithic montmorillonite, 5wt.% PEO, and 20wt.% polysulfone to N-methylpyrrolidone, dissolve and let stand for defoaming to obtain casting solution; use an automatic film applicator The prepared casting solution was applied to the non-woven fabric, and after scraping the film, it was immersed in water for coagulation bath, and the reverse osmosis membrane base film was obtained by the dipping-precipitation phase inversion method; after the base film was dried vertically in the shade, the surface was coated with 2wt. % m-phenylenediamine solution, dried in the shade vertically, and then coated with 0.08wt.% trimesoyl chloride solution for interfacial polymerization reaction, poured out the solution and dried it in a 60°C oven for 10 minutes to prepare a reverse osmosis membrane; Add 0.05w / v.% SDS to the buffer solution as a surfactant, TEA as an acid-binding agent, adjust the pH of the solution to 4.0 with HCl, soak the prepared reverse osmosis membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com