Activated carbon production system integrated with carbon activation

A technology of activated carbon production and carbon activation, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of difficult control of working temperature, uneven carbonization quality, large ash content, etc., to save heat source loss and shorten production time , to achieve the effect of system self-heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

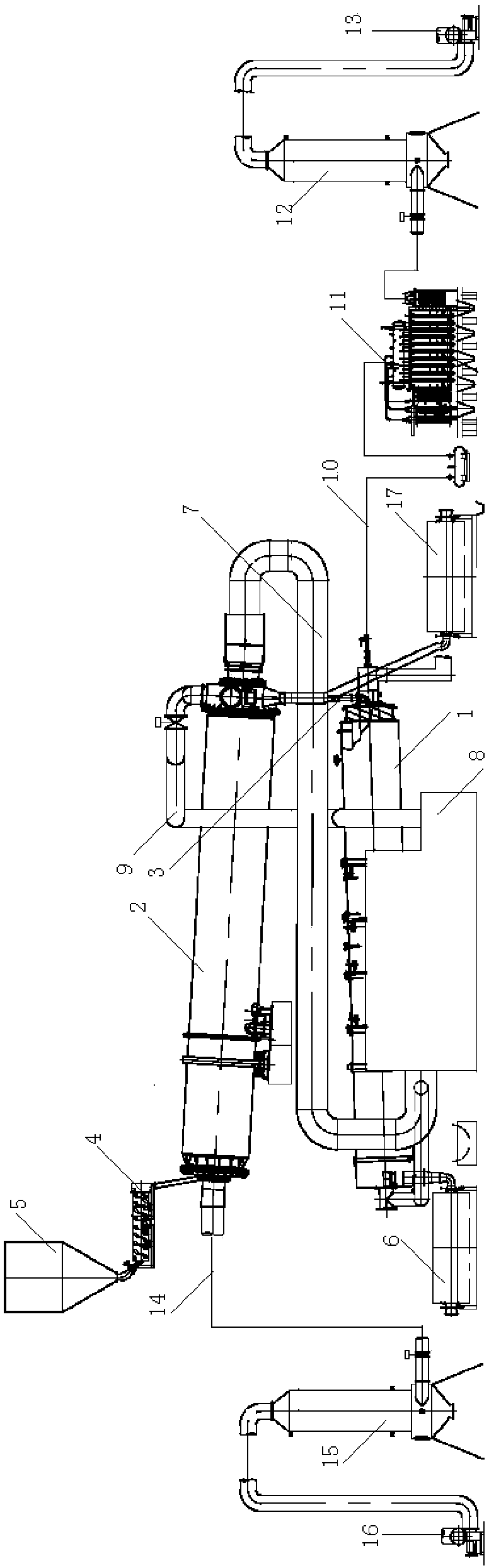

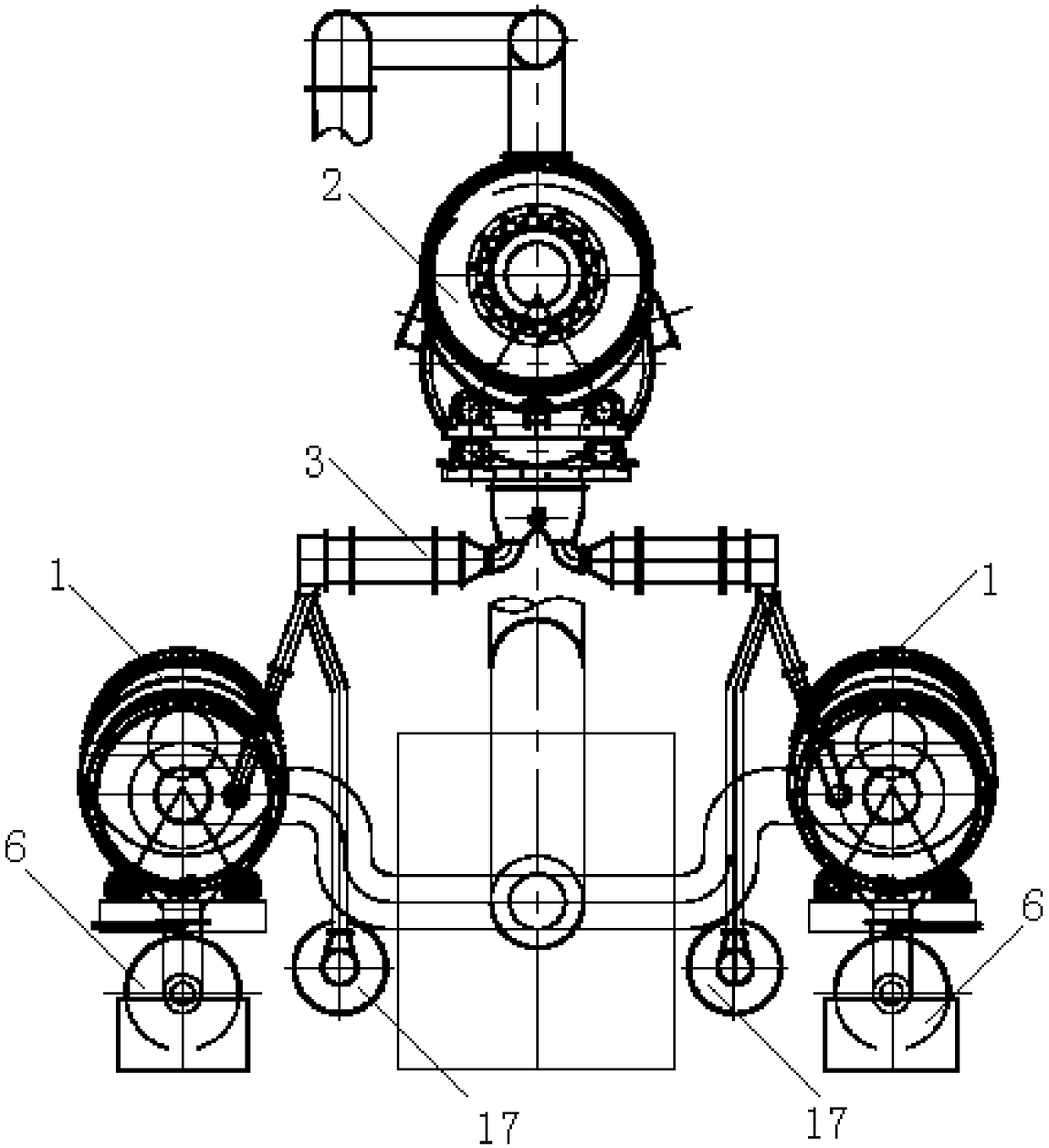

[0011] Referring to the accompanying drawings, a activated carbon production system integrated with carbon activation includes an activation furnace 1 and a carbonization furnace 2. The feed port is connected with a screw feeder 4, the feed port of the screw feeder 4 is connected with a silo 5, the discharge port of the activation furnace 1 is connected with a drum cooler 6, and the combustible gas generated in the carbonization furnace 2 passes through the gas pipeline 7 is connected to the incinerator 8, and the high-temperature gas generated in the incinerator 8 is connected to the carbonization furnace 2 through the high-temperature gas pipeline 9, and the activation furnace 1 is connected to the waste heat boiler 11, the exhaust gas cooler 12, and the induced draft fan 13 in sequence through the activated waste heat waste gas pipeline 10 The carbonization furnace 2 is sequentially connected with a waste gas cooler 15 and an induced draft fan 16 through the carbonization wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com