Preparation method and application of three-dimensional spherical scorodite crystal

A scorodite and spherical technology, which is applied in the field of preparation of three-dimensional spherical scorodite crystals, can solve the problem that the arsenic removal effect needs to be further improved, and achieve the effects of good application potential, efficient removal, and reduction of wastewater treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

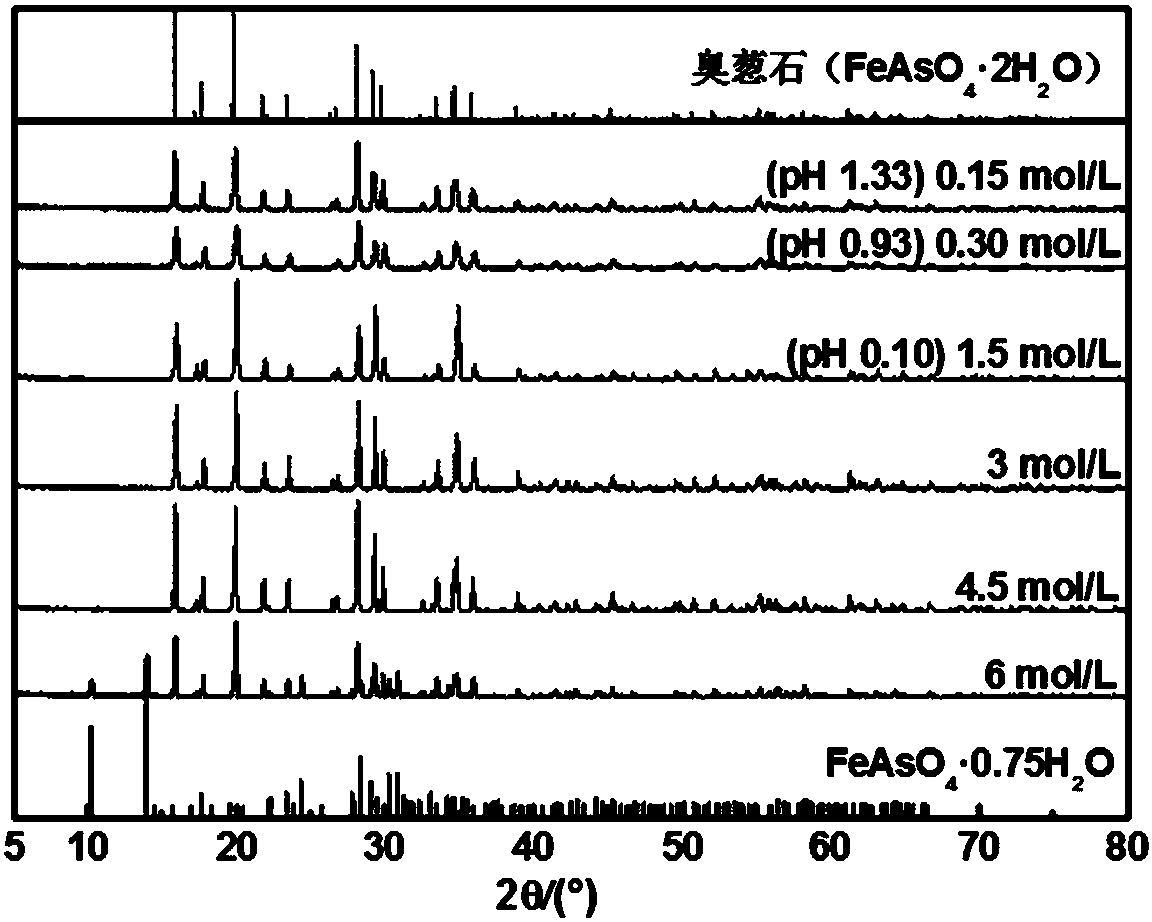

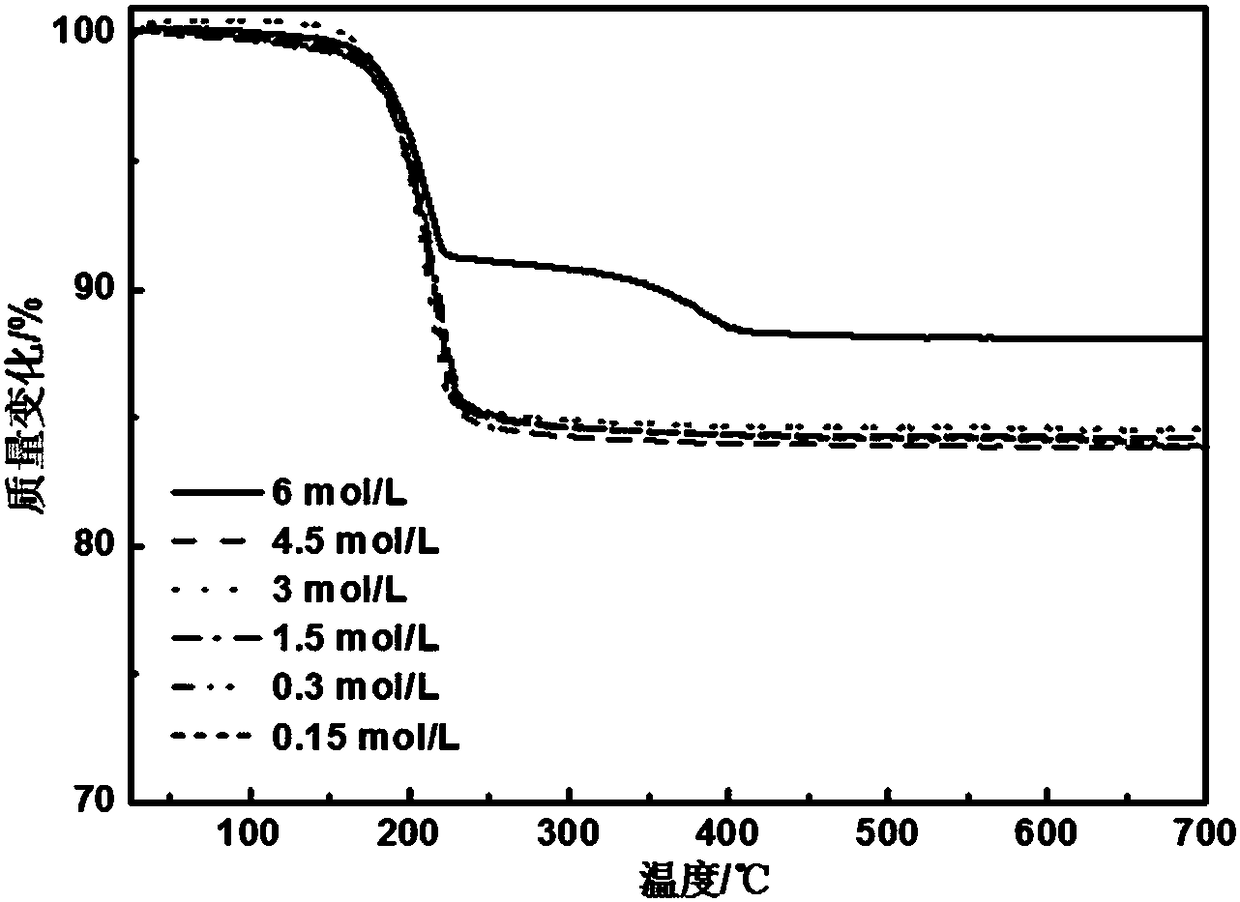

[0035] This embodiment provides a method for preparing three-dimensional spherical scorodite crystals, which includes: weighing ferric nitrate and sodium arsenate solids, making a mixed solution with deionized water and concentrated nitric acid, and the iron concentration and arsenic concentration are both 0.15 mol / L, the concentration of concentrated nitric acid is 0.12mol / L, and the pH of the mixed solution is 1.43. Put the mixed solution into a 50mL autoclave, and place it in an oven at 200°C for 12 hours. After the reaction, the solution naturally After cooling to room temperature, it was separated by suction filtration, and the filter residue was washed with deionized water and then dried at 60°C to obtain a solid sample.

Embodiment 2

[0037] This example provides a method for preparing three-dimensional spherical scorodite crystals. The difference from Example 1 is that the concentration of nitric acid added is 0.15 mol / L, and the pH of the mixed solution is 1.33.

Embodiment 3

[0039] This example provides a method for preparing three-dimensional spherical scorodite crystals. The difference from Example 1 is that the concentration of nitric acid added is 0.18 mol / L, and the pH of the mixed solution is 1.20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com