Household kitchen waste fertilizer treatment device and treatment method thereof

A processing method and processor technology, applied in biochemical equipment and methods, biochemical instruments, organic fertilizers, etc., can solve problems such as difficult rapid extrusion of solid-liquid and oil-water separation, breeding of bacteria, and difficult processing, so as to promote development The effect of modern urban agriculture, reducing the pressure of processing, and prolonging the digestion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

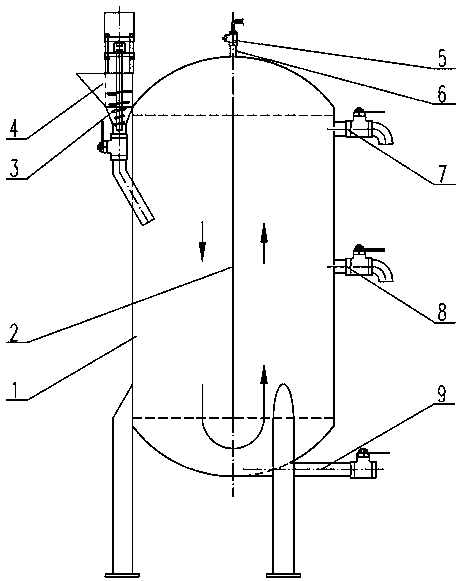

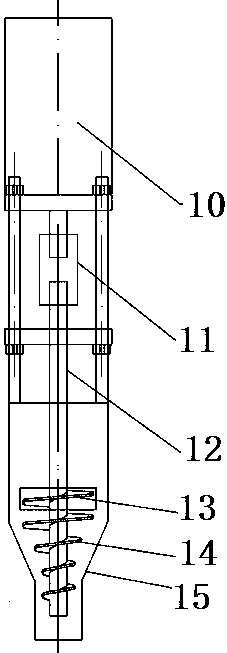

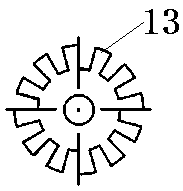

[0028] A household food waste fertilizer processor, comprising a vertical tank body 1, the inside of the tank body 1 is provided with a deflector plate 2, the deflector plate 2 is perpendicular to the central position of the tank body 1, and the deflector plate 2 guides the tank body 1 The inner cavity is divided into two reaction chambers, the upper part of the two reaction chambers is connected through the inner cavity of the top of the tank body 1, and the lower part is connected through the inner cavity of the bottom of the tank body 1; The feed bin 4 is externally connected, the crushing propeller 3 is arranged inside the feed bin 4, the discharge pipe is arranged on the other side of the tank body 1, the bottom mud discharge pipe 9 is arranged at the bottom of the tank body 1, and the discharge pipe 9 is arranged on the top of the tank body 1. The air pipe 6 and the exhaust pipe 6 are provided with a pressure relief valve 5 .

[0029] In this embodiment, the deflector 2 ...

Embodiment 2

[0039] This embodiment further describes the present invention in conjunction with the accompanying drawings, but the present invention is not limited to the described embodiment.

[0040] In this example, the household food waste fertilizer processor is as follows: figure 1 As shown, it is mainly composed of a tank body 1. The tank body 1 is a vertical tank, and a deflector 2 is arranged inside the tank body; The silo 4 has a built-in crushing propeller 3; the other side of the tank body is equipped with a high-level discharge pipe 7 and a middle discharge pipe 8, and the bottom of the tank is provided with a bottom mud discharge pipe 9; Install pressure relief valve 5 above.

[0041] In this example, the effective volume of the fermenter body 1 should meet the requirement that the material digestion time is greater than 40 days.

[0042] In this example, the deflector 2 should be placed in the vertical central position inside the tank, and the processor is divided into two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com