Preparation method and application of modified short-straight-chain starch

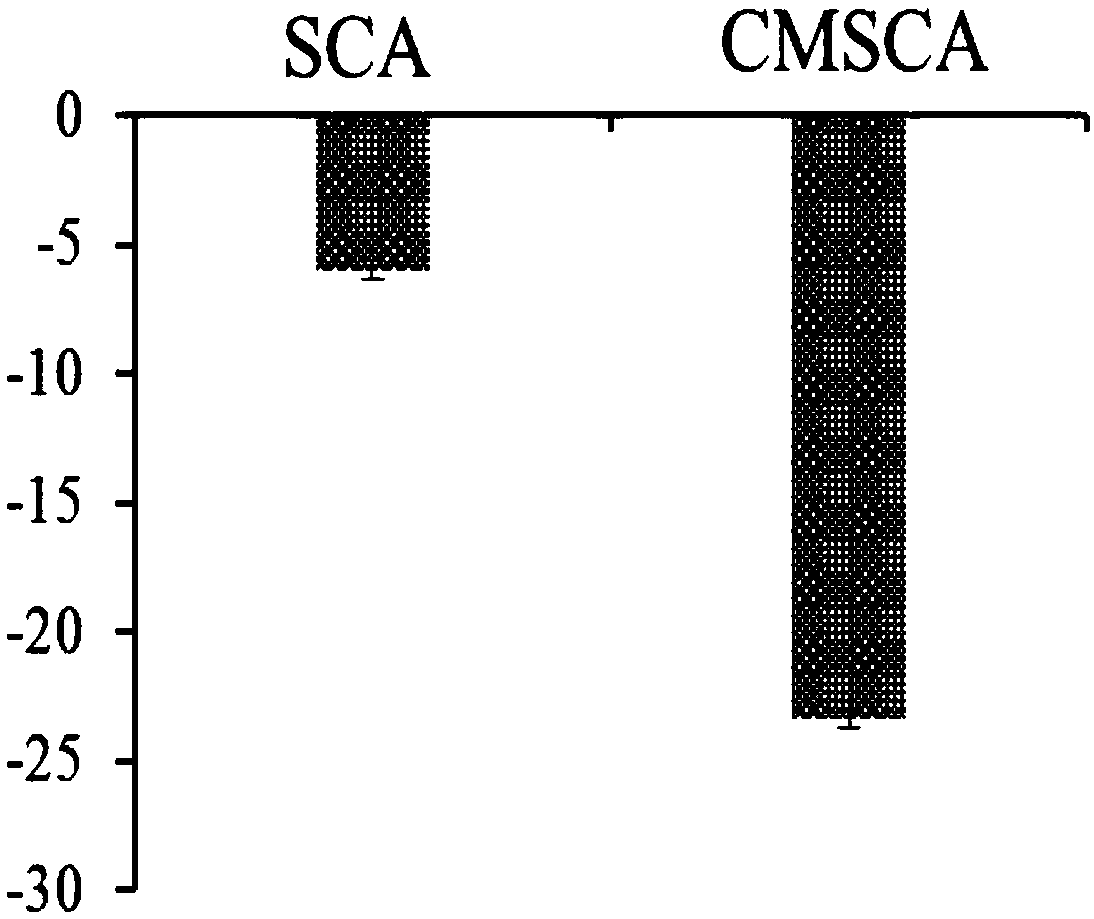

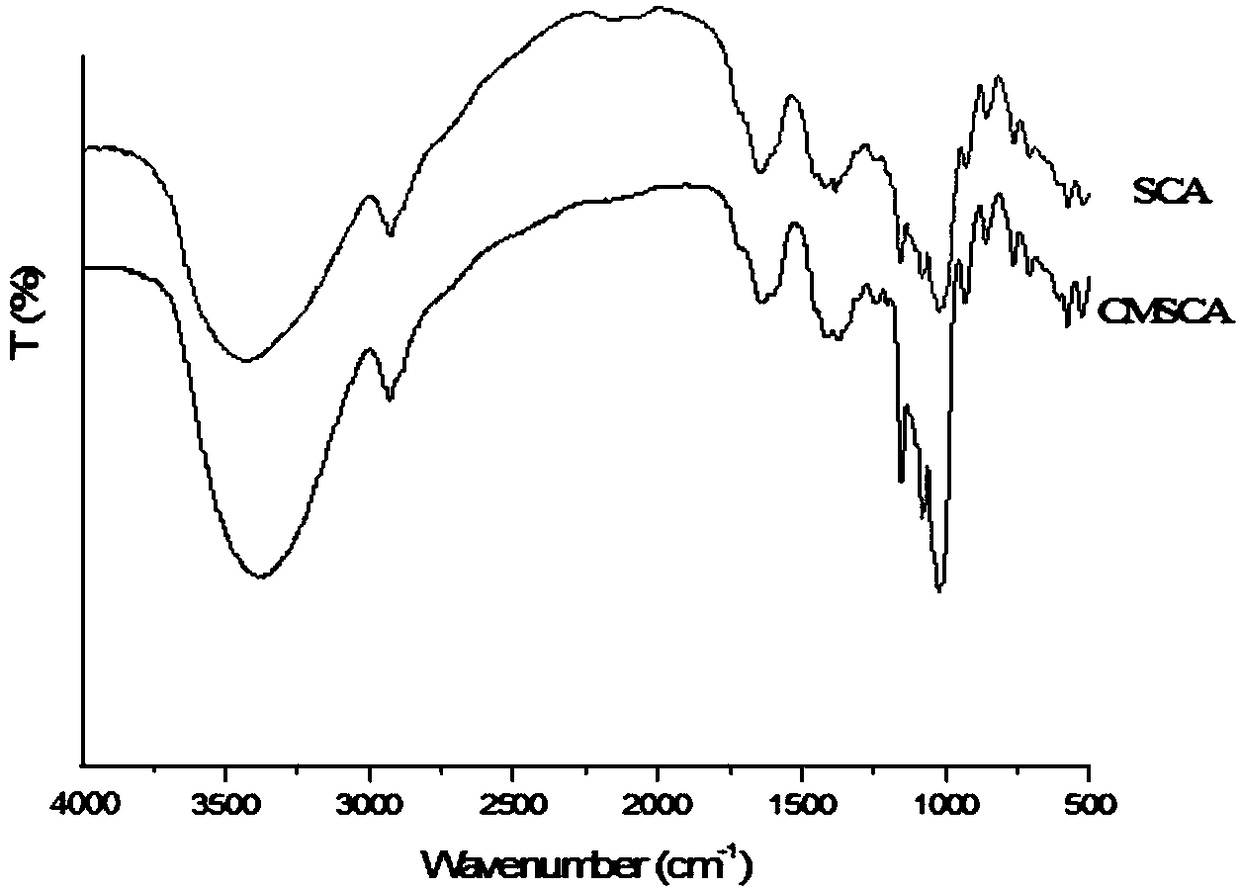

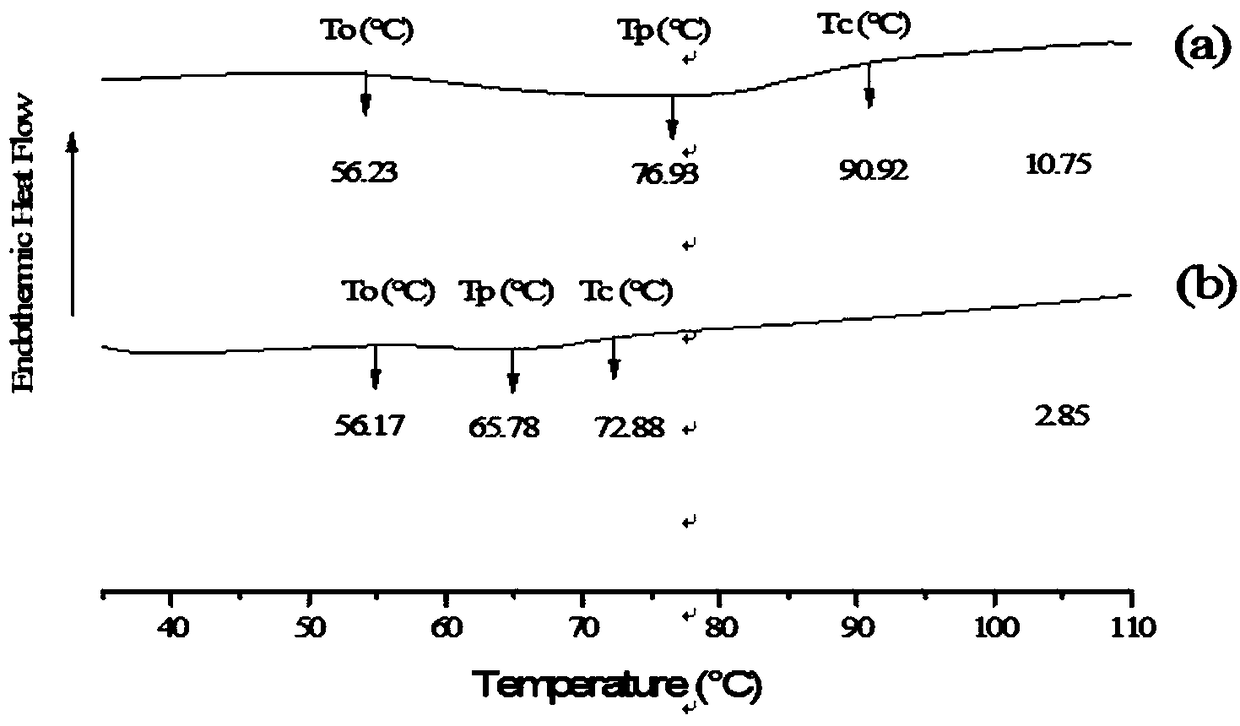

A technology of short amylose and carboxymethyl short amylose, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulations, etc. The problem of low starch charge and easy aggregation has achieved the effect of green and environmental protection in the preparation process, simple preparation method and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The influence of embodiment 1 ethanol solution volume concentration and starch milk concentration on the properties of short amylose

[0040] (1) Use ethanol solution to adjust the short amylose solution into starch milk with a concentration of 10%, and the volume concentration of the ethanol solution is as shown in Table 1;

[0041] (2) under stirring state, add 2g sodium hydroxide to described starch slurry, react, control reaction temperature to be 40 ℃, reaction time is 1h;

[0042] (3) Add 2g of chloroacetic acid to the reaction system treated in (2), the time of adding chloroacetic acid is controlled at 10min, and the reaction temperature is 40°C;

[0043] (4) After etherification, adjust the pH value to 7.0 with hydrochloric acid, wash with ethanol with a volume concentration of 90%, filter, dry, pulverize, and sieve to obtain carboxymethyl-modified short amylose.

[0044] Table 1 The influence of volume concentration of ethanol solution on the properties of sho...

Embodiment 2

[0048] The effect of embodiment 2 sodium hydroxide addition amount on short amylose properties

[0049] (1) Use the ethanol solution with a volume concentration of 80% to adjust the short amylose solution into starch milk with a concentration of 10%;

[0050] (2) Under stirring state, add sodium hydroxide to described starch slurry, react, control reaction temperature to be 40 ℃, reaction time is 1h, the addition amount of sodium hydroxide is as shown in table 2;

[0051] (3) Add 2g of chloroacetic acid to the reaction system treated in (2), the time of adding chloroacetic acid is controlled at 10min, and the reaction temperature is 40°C;

[0052] (4) After etherification, adjust the pH value to 7.0 with hydrochloric acid, wash with ethanol with a volume concentration of 90%, filter, dry, pulverize, and sieve to obtain carboxymethyl-modified short amylose.

[0053] Table 2 The effect of sodium hydroxide addition on the properties of short amylose

[0054]

[0055] As can ...

Embodiment 3

[0056] The impact of embodiment 3 chloroacetic acid on the properties of short amylose

[0057] (1) Use the ethanol solution with a volume concentration of 80% to adjust the short amylose solution into starch milk with a concentration of 10%;

[0058] (2) under stirring state, add 2g sodium hydroxide to described starch slurry, react, control reaction temperature to be 40 ℃, reaction time is 1h;

[0059] (3) Add chloroacetic acid in the reaction system processed through (2), the time of adding chloroacetic acid is controlled at 10min, the reaction temperature is 40°C, and the addition amount of chloroacetic acid is as shown in table 3;

[0060] (4) After etherification, adjust the pH value to 7.0 with hydrochloric acid, wash with ethanol with a volume concentration of 90%, filter, dry, pulverize, and sieve to obtain carboxymethyl-modified short amylose.

[0061] Table 3 The effect of chloroacetic acid addition on the properties of short amylose

[0062]

[0063] It can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com