Planar anisotropic magnetoresistive film and preparation method thereof

An anisotropic magnetic and thin film technology, applied in the direction of measuring magnetic variables, ion implantation plating, coating, etc., can solve the problems of small magnetoresistance effect, small anisotropic magnetoresistance effect, simple layer structure, etc., and achieve magnetic Increased resistance effect, small temperature coefficient of magnetoresistance, avoiding low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

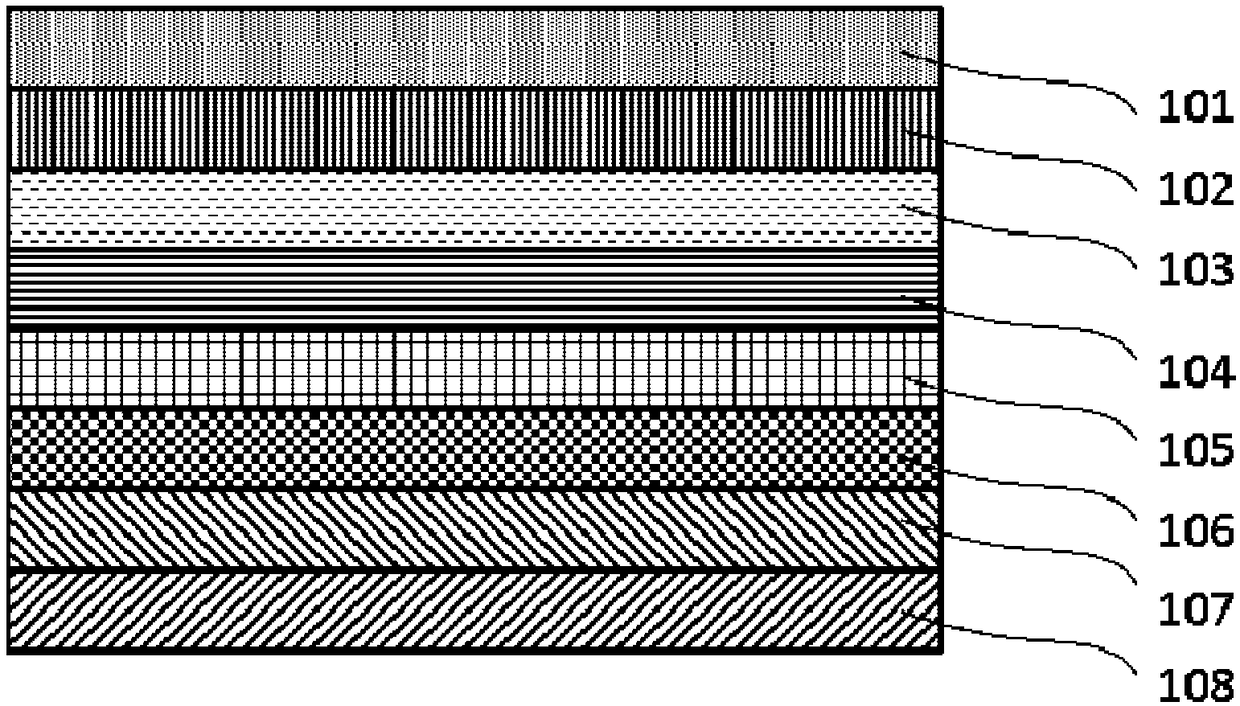

[0021] A planar anisotropic magnetoresistive film was prepared by the following method. A glass substrate is provided; a CoO layer is deposited on a glass substrate by reactive magnetron sputtering with metal Co as a target; 1-x Sr x CoO 3 As the target, magnetron sputtering was used to deposit La on the CoO layer 1-x Sr x CoO 3 layer, where x=0.1; using metal Fe as the target, using magnetron sputtering, in La 1-x Sr x CoO 3 The Fe layer is deposited on the Fe layer; the first FePt layer is deposited on the Fe layer by magnetron sputtering with FePt alloy as the target; the first FePt layer is deposited on the first FePt layer by reactive magnetron sputtering with Ni as the target NiO layer; Fe is deposited on the NiO layer by reactive magnetron sputtering using metal Fe as the target 3 o 4 layer; and using FePt alloy as target material, using magnetron sputtering, in Fe 3 o 4 A second layer of FePt is deposited on top of the layer. The thickness of the CoO layer ...

Embodiment 2

[0023] A planar anisotropic magnetoresistive film was prepared by the following method. A glass substrate is provided; a CoO layer is deposited on a glass substrate by reactive magnetron sputtering with metal Co as a target; 1-x Sr x CoO 3 As the target, magnetron sputtering was used to deposit La on the CoO layer 1-x Sr x CoO 3 layer, where x=0.13; using metal Fe as the target, using magnetron sputtering, in La 1-x Sr x CoO 3 The Fe layer is deposited on the Fe layer; the first FePt layer is deposited on the Fe layer by magnetron sputtering with FePt alloy as the target; the first FePt layer is deposited on the first FePt layer by reactive magnetron sputtering with Ni as the target NiO layer; Fe is deposited on the NiO layer by reactive magnetron sputtering using metal Fe as the target 3 o 4 layer; and using FePt alloy as target material, using magnetron sputtering, in Fe 3 o 4 A second layer of FePt is deposited on top of the layer. The thickness of the CoO layer...

Embodiment 3

[0025] A planar anisotropic magnetoresistive film was prepared by the following method. A glass substrate is provided; a CoO layer is deposited on a glass substrate by reactive magnetron sputtering with metal Co as a target; 1-x Sr x CoO 3 As the target, magnetron sputtering was used to deposit La on the CoO layer 1-x Sr x CoO 3 layer, where x=0.12; using metal Fe as the target, using magnetron sputtering, in La 1-x Sr x CoO 3 The Fe layer is deposited on the Fe layer; the first FePt layer is deposited on the Fe layer by magnetron sputtering with FePt alloy as the target; the first FePt layer is deposited on the first FePt layer by reactive magnetron sputtering with Ni as the target NiO layer; Fe is deposited on the NiO layer by reactive magnetron sputtering using metal Fe as the target 3 o 4 layer; and using FePt alloy as target material, using magnetron sputtering, in Fe 3 o 4 A second layer of FePt is deposited on top of the layer. The thickness of the CoO layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com