Preparation method of clay mineral hybridized cobalt blue pigment

A clay mineral, hybrid technology, applied in chemical instruments and methods, inorganic pigment processing, cobalt compounds, etc., to achieve the effects of low energy consumption, high yield, and avoidance of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

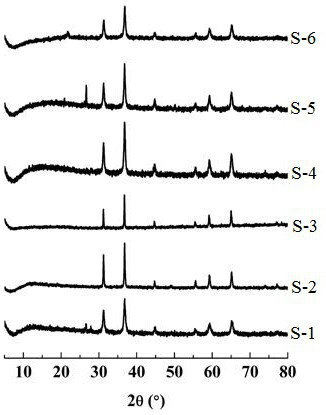

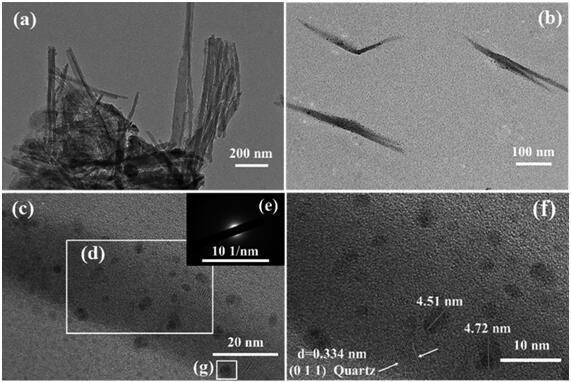

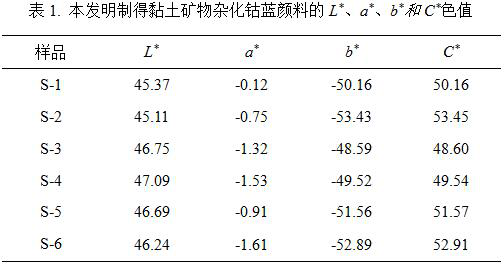

[0023] Put 100 g of attapulgite, 97.61 g of cobalt nitrate, 125.82 g of aluminum nitrate and 122.83 g of aluminum sulfate into a differential-speed co-rotating twin-screw extruder to obtain a precursor. Clay mineral hybrid cobalt blue pigment, the corresponding samples are marked as S-1, L * , a * , b * See Table 1 for color values.

Embodiment 2

[0025] 60 g of kaolinite, 40 g of sepiolite, 95.36 g of cobalt sulfate, 54.58 g of aluminum chloride and 35.27 g of aluminum hydroxide were extruded into a co-rotating twin-screw extruder to obtain a precursor, which was crystallized at 1000ºC for 90 min later, the clay mineral hybrid cobalt blue pigment was obtained by crushing, and the corresponding samples were marked as S-2, L * , a * , b * See Table 1 for color values.

Embodiment 3

[0027] Put 50g montmorillonite, 50g dickite, 20g attapulgite, 32.68g tricobalt tetroxide, 33.80g cobalt acetate, 27.66g alumina and 128.75g aluminum potassium sulfate into co-rotating twin-screw extruder to extrude The precursor was crystallized at 950ºC for 30 minutes, then pulverized to obtain a clay mineral hybrid cobalt blue pigment. The corresponding samples were marked as S-3, L * , a * , b * See Table 1 for color values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com