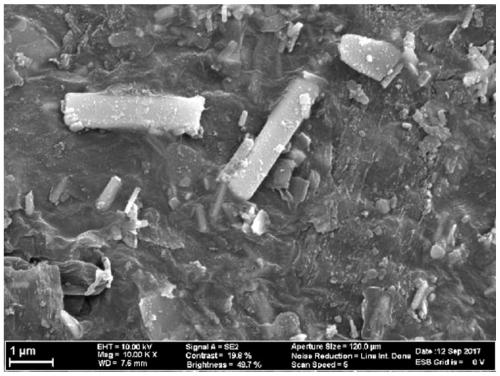

Preparation method IXXX negative electrode foil for aluminum electrolyte capacitor

A technology of aluminum electrolytic capacitors and cathode foils, applied in the direction of electrolytic capacitors, capacitor electrodes, capacitors, etc., can solve problems such as cracks and poor plate shape, easy deviation during hot rolling, uneven ingot structure, etc., reaching the second The phase distribution is uniform, which is beneficial to the uniformity of corrosion and the effect of avoiding uneven structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of manufacturing method of 1XXX series cathode foil for aluminum electrolytic capacitor, the method comprises the following steps:

[0051] S1. Prepare casting and rolling blanks according to the following components and mass percentages: mix ingredients according to the alloy composition in Table 1, control the temperature of the melting furnace at 745°C, feed nitrogen, refine for 15 minutes, remove slag and stir sufficiently, take samples, analyze and adjust after passing the test. Put it into the static furnace, stand still for 20 minutes, the temperature of the static furnace is 736°C, refine and remove the slag in the static furnace, use a silicon nitride rotor for degassing at 505rpm, and then send it to the casting-rolling machine, the casting-rolling temperature is 697°C, the casting-rolling speed is 730mm / min, the casting-rolling Finally, a 7.1mm cast-rolled coil is obtained;

[0052] S2. Cold rolling and foil rolling: cold rolling and foil rolling the c...

Embodiment 2

[0058] Obtain cast-rolled coil according to embodiment 1, cast-rolled coil is through cold-rolling-edge trimming-cold rolling-edge trimming-intermediate cleaning-foil rolling to finished product thickness-finished product cleaning-slitting-finished product annealing, before rolling to finished product thickness Any heat treatment is required, the thickness of the finished product is 0.050mm, the product state is O state, the annealing process of the finished product: 305°C*25h, the product strength is 56MPa, the specific volume of the product is qualified after the trial by the customer B manufacturer, reaching 100.6% of the specific volume of the hot-rolled material .

Embodiment 3

[0060] A kind of manufacturing method of 1XXX series cathode foil for aluminum electrolytic capacitor, the method comprises the following steps:

[0061] S1. Prepare casting and rolling blanks according to the following components and mass percentages: mix ingredients according to the alloy composition in Table 1, control the temperature of the melting furnace at 737°C, feed nitrogen, refine for 15 minutes, remove slag, stir well, take samples, analyze and adjust after passing the test. Put it into the static furnace, stand still for 20 minutes, the temperature of the static furnace is 730°C, refine and remove the slag in the static furnace, use a silicon nitride rotor to degas at 505rpm, and then send it to the casting and rolling machine, the casting temperature is 688°C, the casting and rolling speed is 950mm / min, the casting and rolling Finally, a 5.8mm cast-rolled coil is obtained;

[0062] S2. Cold rolling and foil rolling: cold rolling and foil rolling the casting bille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com