Potassium/potassium ferrite/Prussian blue solid state battery and preparing method thereof

A Prussian blue, solid-state battery technology, applied in the field of electrochemistry, can solve the problems of slow cost reduction and slow increase in energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

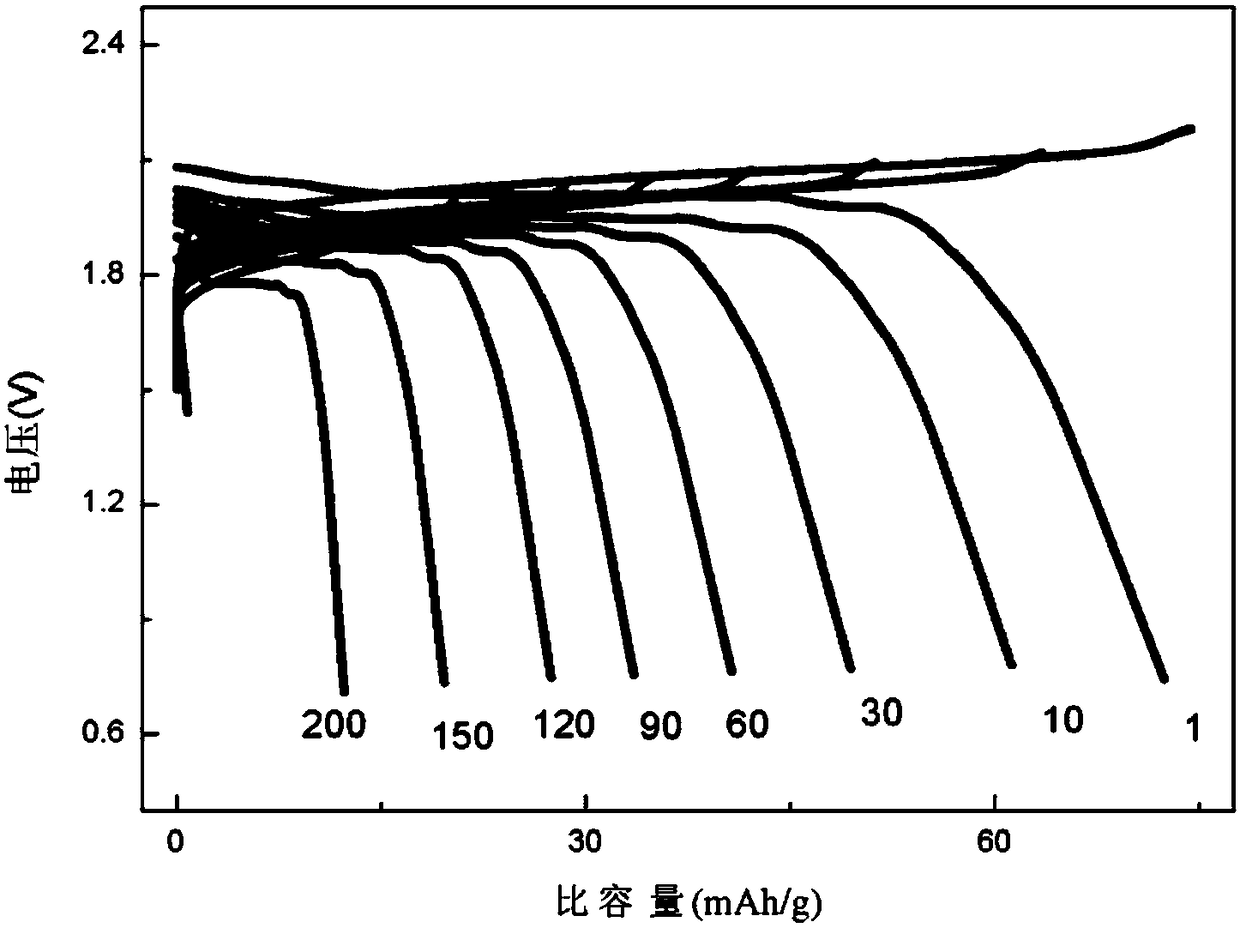

Embodiment 1

[0022] (1) 1.2g KFeFe(CN) 6 , 0.6g molecular formula is K 2 Fe 4 o 7 Potassium ferrite 1, 0.2g acetylene black, 0.2g polyvinylidene fluoride (PVDF) and 0.5g N-class-2-pyrrolidone (NMP) are mixed and fully ground and mixed in a mortar to obtain a mixture; Apply the above mixture on aluminum foil, and dry it under vacuum at 120° C. for 24 hours to obtain Prussian blue sheet 2;

[0023] (2) Press potassium ferrite 2 into thin sheets, and sinter at 650°C to obtain potassium ferrite sheets;

[0024] (3) Stack the Prussian blue sheet, potassium ferrite sheet and metal potassium sheet together to assemble a 2032 type potassium / potassium ferrite / Prussian blue solid-state battery 1.

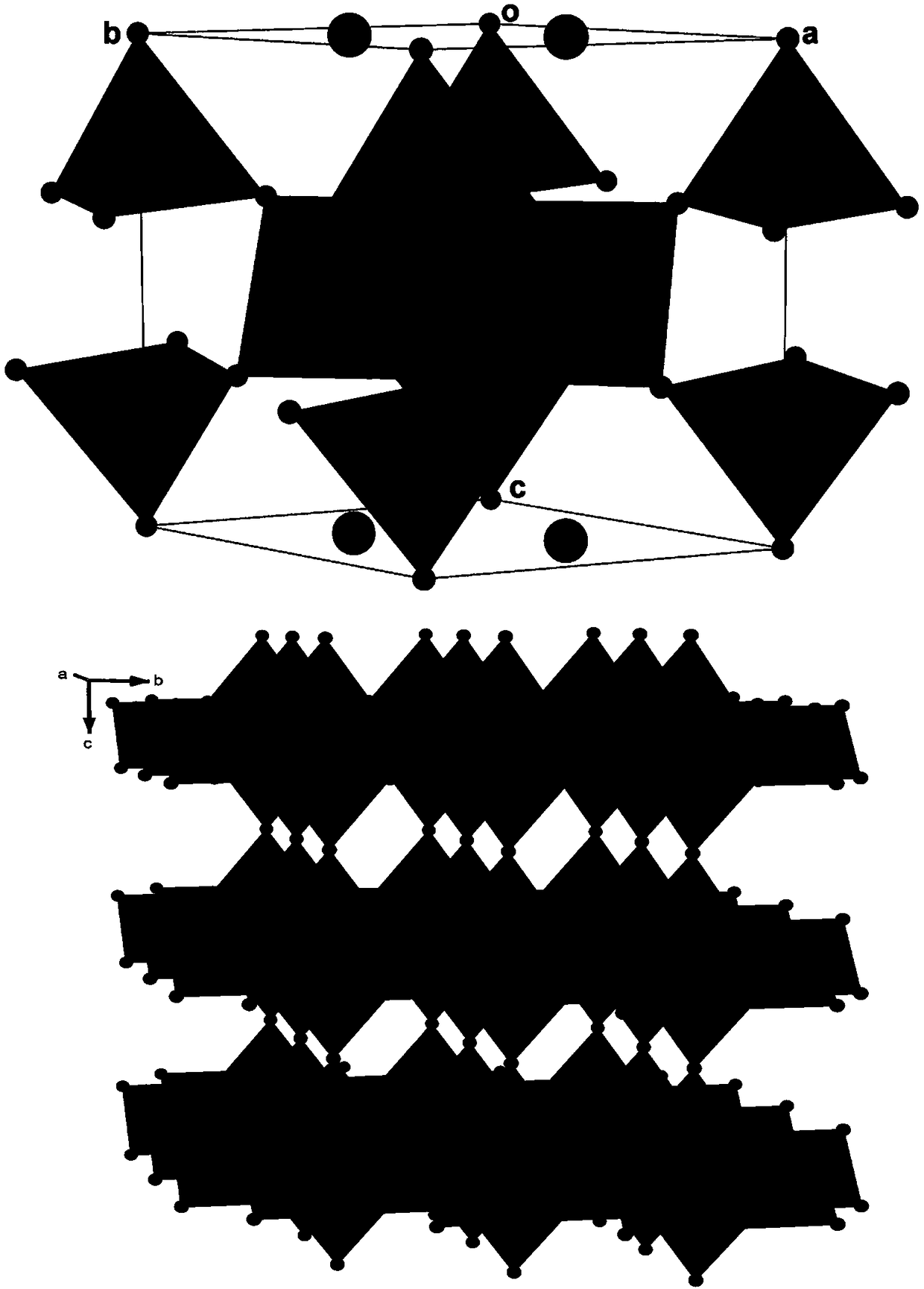

[0025] Potassium ferrite used in the present invention is a novel electrolyte material with a three-dimensional network structure, and its structure is as follows: figure 1 shown.

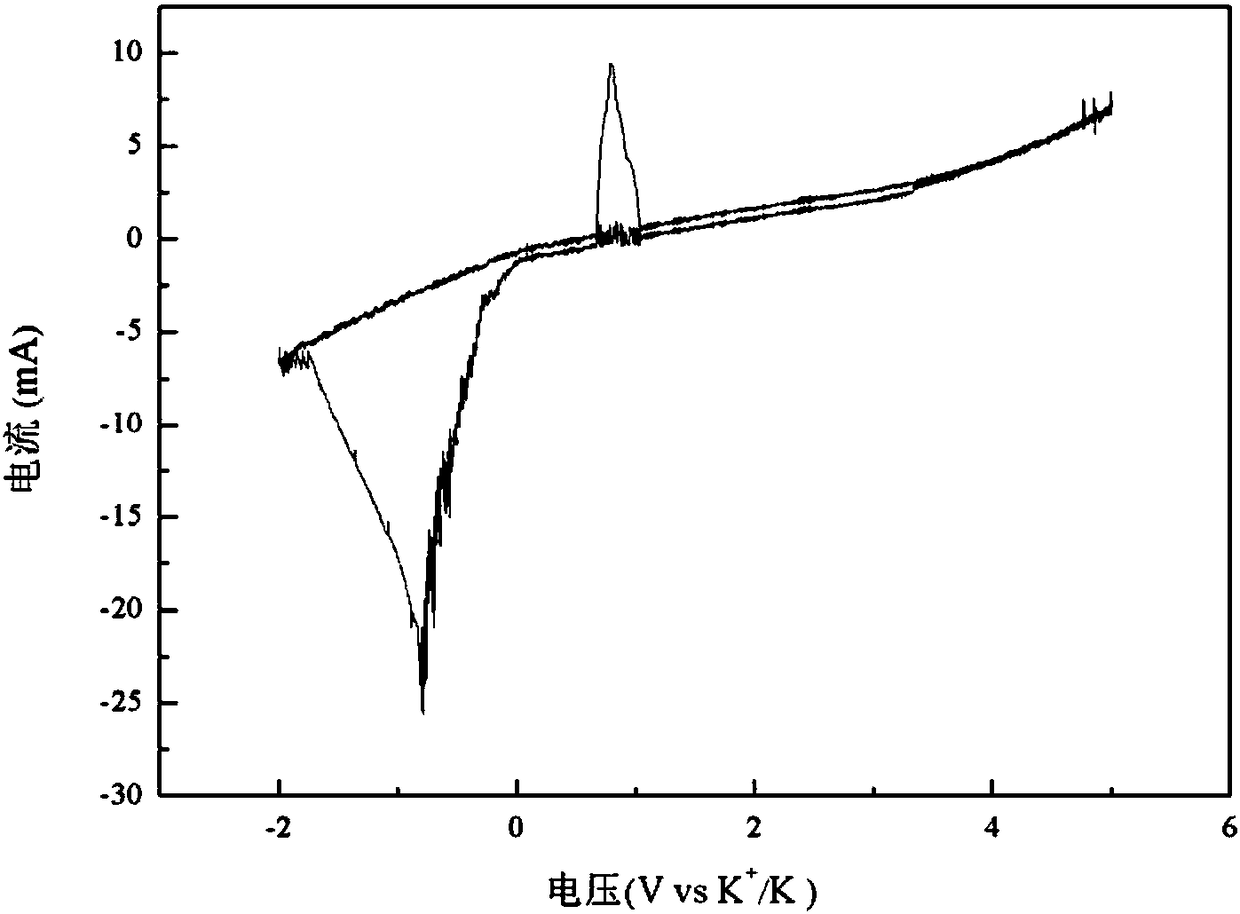

[0026] The electrochemical stability of potassium ferrite material in the present invention is determined by cyclic vo...

Embodiment 2

[0030] (1) Add 1.g KFeFe(CN) 6 , 0.2g molecular formula is K 2 Fe 4 o 7 Potassium ferrite 1, 0.4g acetylene black, 0.4g polyvinylidene fluoride (PVDF) and 0.5g N-class-2-pyrrolidone (NMP) are mixed and fully ground and mixed in a mortar to obtain a mixture; Apply the above mixture on aluminum foil, and dry it under vacuum at 120° C. for 24 hours to obtain Prussian blue sheet 2;

[0031] (2) The molecular formula is K 2 Fe 4 o 7 Potassium ferrite 2 is pressed into thin sheets and sintered at 650°C to obtain potassium ferrite sheets 2;

[0032] (3) Stack the Prussian blue sheet 2, the potassium ferrite sheet 2 and the metal potassium sheet to form a 2032 type potassium / potassium ferrite / Prussian blue solid-state battery 2.

[0033] The specific capacity of the 2032 type potassium / potassium ferrite / Prussian blue solid-state battery 2 at the rate of 1C for the first charge and discharge is 70mAh / g.

Embodiment 3

[0035] (1) 1.2g KFeFe(CN) 6 , 0.6g molecular formula is K 2 Fe 4 o 7 Potassium ferrite 1, 0.2g acetylene black, 0.2g polyvinylidene fluoride (PVDF) and 0.5g N-a-2-pyrrolidone (NMP) were mixed and then fully ground and mixed in a mortar to obtain a mixture; Apply the above mixture on aluminum foil, and dry it under vacuum at 120° C. for 24 hours to obtain Prussian blue sheet 3;

[0036] (2) The molecular formula is K 2 Fe 4 o 7 Potassium ferrite 2 is pressed into thin sheets and sintered at 650°C to obtain potassium ferrite sheets;

[0037] (3) Stack the Prussian blue sheet 3 , potassium ferrite sheet 3 and metal potassium sheet to form a 2016 type potassium / potassium ferrite / Prussian blue solid-state battery 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| First charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com