Bio-electrocatalytic coupled contact oxidation denitrification filtration integrated bioreactor

A bioreactor, contact oxidation technology, applied in the direction of electrochemical biological combination treatment, filtration treatment, chemical instruments and methods, etc., can solve the problem of difficult to meet the effluent water quality standard, low biodegradability of printing and dyeing wastewater, and difficulty in completely removing the pollution of printing and dyeing wastewater reduce the burden of sludge treatment, low sludge output, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The bioelectrocatalytic coupled contact oxidation denitrification filtration integrated bioreactor involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0031]

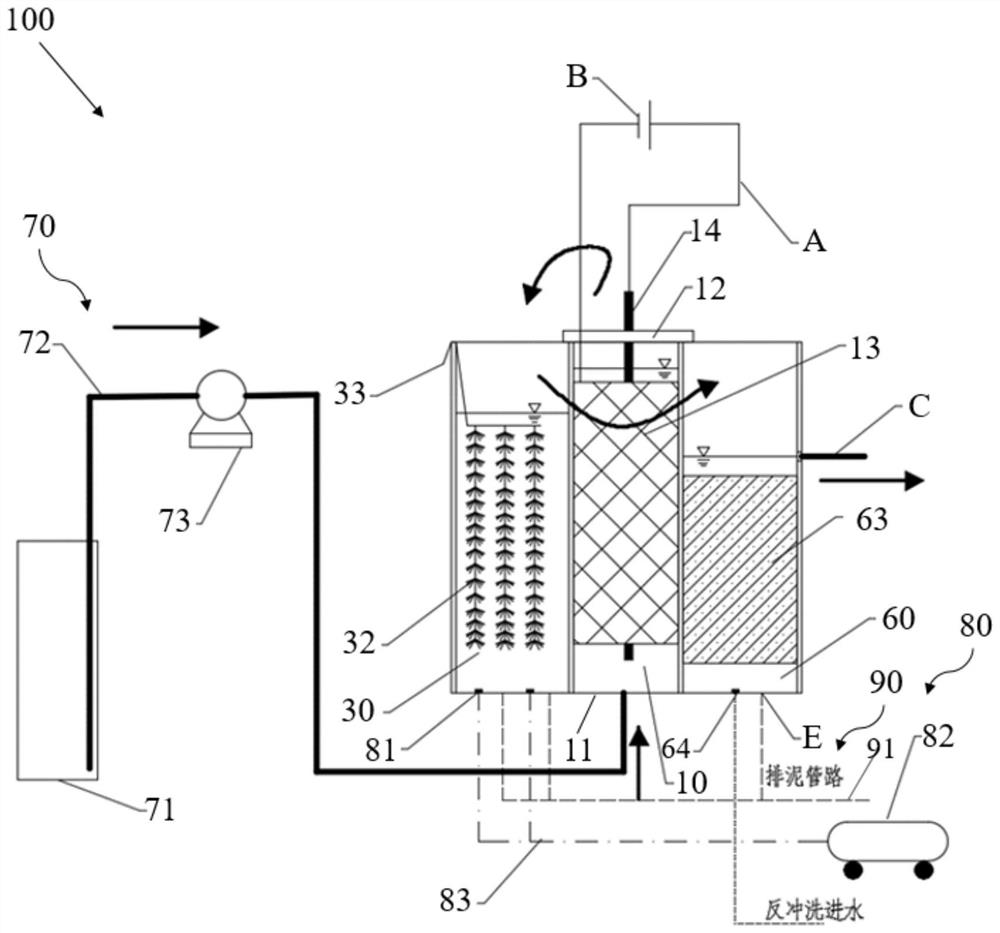

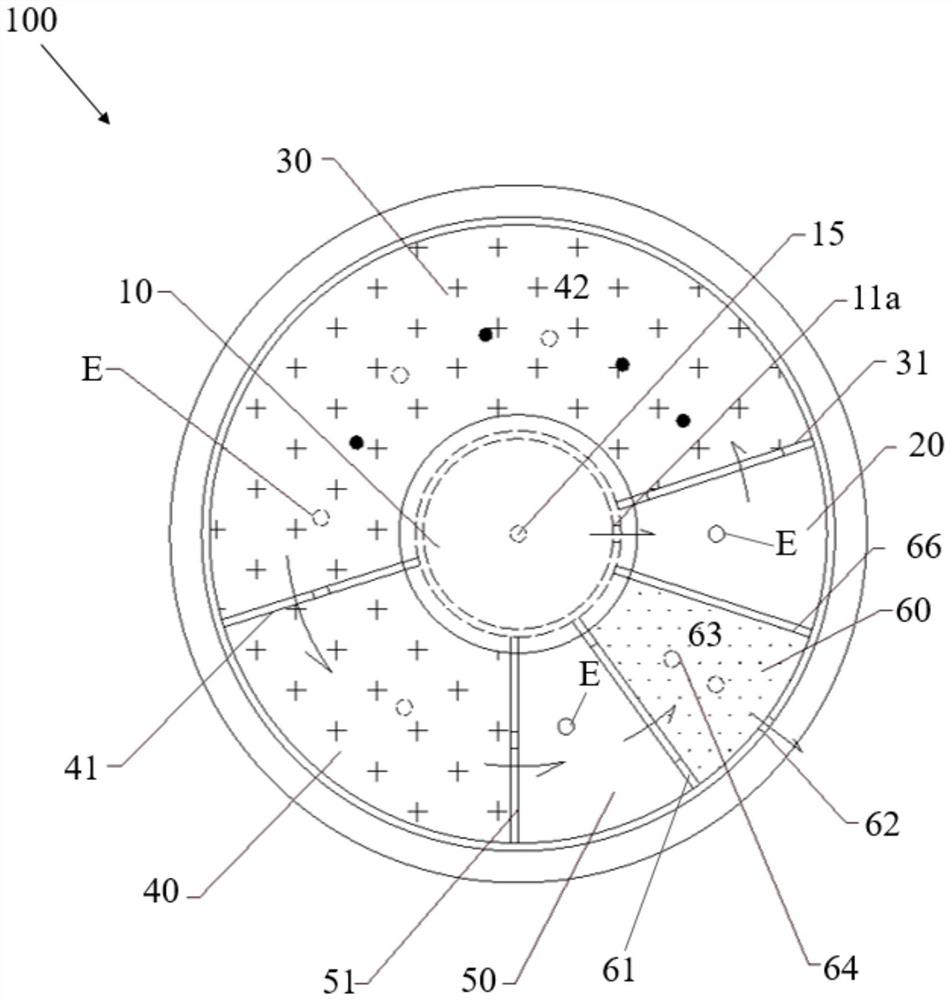

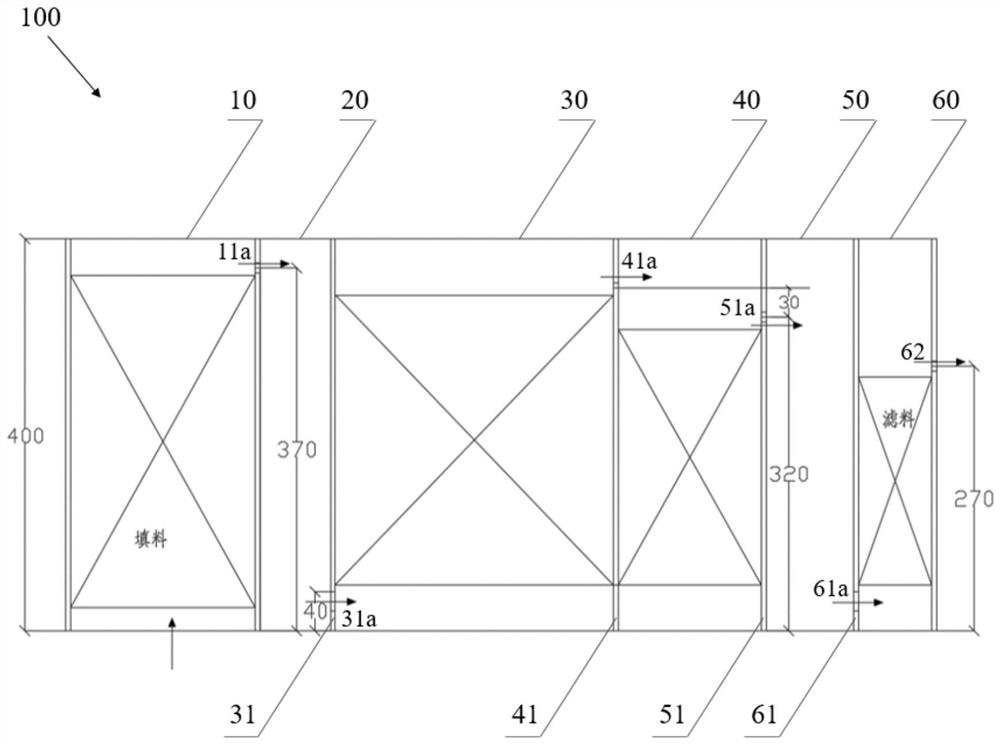

[0032] Such as figure 1 and 2 As shown, the integrated bioreactor 100 of bioelectrocatalysis coupling contact oxidation denitrification filtration has: bioelectrocatalysis cell 10, first water collection pool 20, contact oxidation pool 30, denitrification pool 40, second water collection pool 50, filter Pool 60 , water inlet part 70 , aeration part 80 , and mud discharge part 90 .

[0033] The bio-electrocatalytic cell 10, the first water collection pool 20, the contact oxidation pool 30, the denitrification pool 40, the second water collection pool 50, and the filter pool 60 form a cylindrical structure, wherein the bio-electrocatalytic cell 10 is located in the middle as the inner area , with an inner diameter of 120mm, a wall thickness of 5mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com