A silicon-based photoelectrode, its preparation method and application

A photoelectrode, silicon-based technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of low catalytic efficiency and poor electrochemical activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

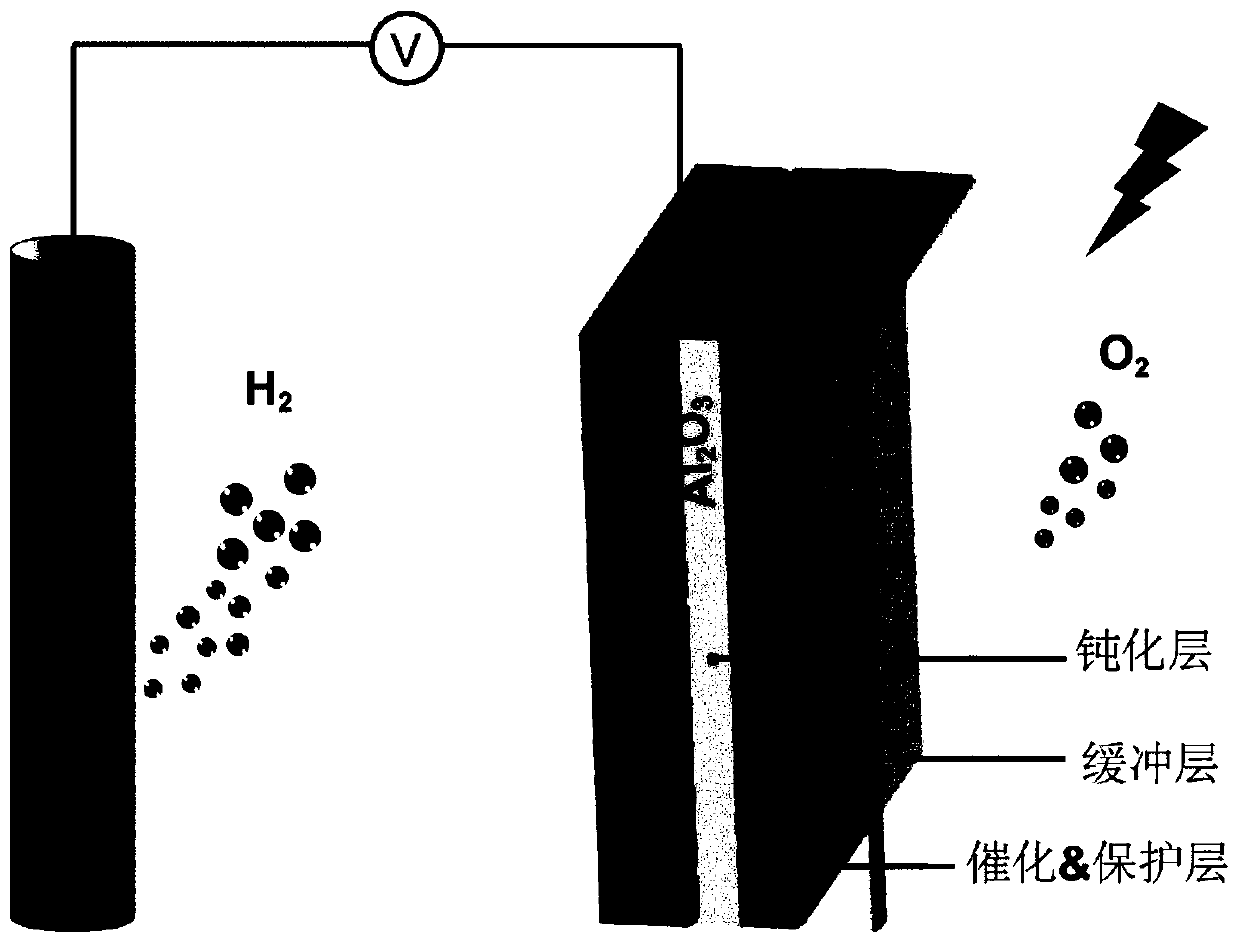

[0069] A method for preparing a silicon-based photoelectrode comprises the steps of:

[0070] (1) Ultrasonic cleaning of a 1 cm × 1 cm Si wafer in acetone, isopropanol and deionized water three times, each time for 5 minutes, and then drying with nitrogen, and soaking the dried silicon wafer in 3% HF solution 2 minutes to remove the natural oxide layer on the surface of the silicon wafer, then rinse repeatedly with deionized water to clean the residual HF on the surface, and blow dry with nitrogen;

[0071] (2) Using trimethylaluminum as Al precursor, deionized water as oxygen source, N 2 As a carrier gas, the sample is first evacuated to a vacuum at a pressure of about 0.2 Pa, and then the HF etched Si substrate is heated to 200°C. Each cycle of ALD includes a 15ms trimethylaluminum pulse and a 15s nitrogen purge. , 15ms deionized water pulse and 15s nitrogen purge, cycle 25 circles to obtain a passivation layer with a thickness of 2.2nm, the passivation layer is Al 2 o 3 ...

Embodiment 2

[0075] The difference from Example 1 is that in step (4), a nickel-iron alloy with a nickel:iron atomic ratio of 9:1 is used as the target material, and the iron content in the catalytic protective layer is 5.79%.

Embodiment 3

[0077] The difference from Example 1 is that in step (4), a nickel-iron alloy with a nickel:iron atomic ratio of 2:1 is used as the target material, and the iron content in the catalytic protective layer is 9.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com