Resistivity wide-distributed conductive composite material and preparation method thereof

A conductive composite material and composite material technology, applied in the field of conductive composite materials with wide distribution of resistivity and its preparation, can solve the problems that it is difficult to achieve the effect, the chopped carbon fibers cannot be completely dispersed, and the conductive network cannot be overlapped with each other. Good heat resistance and corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

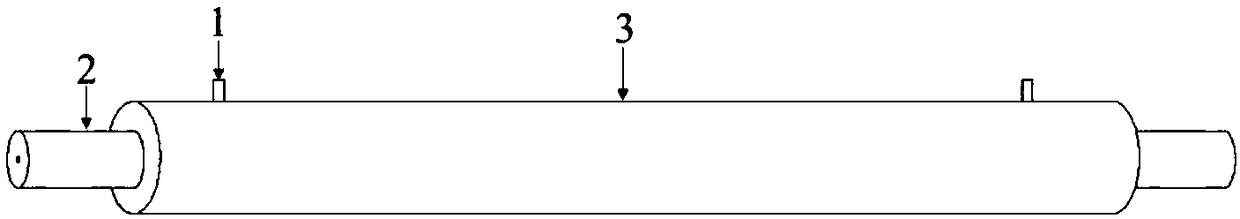

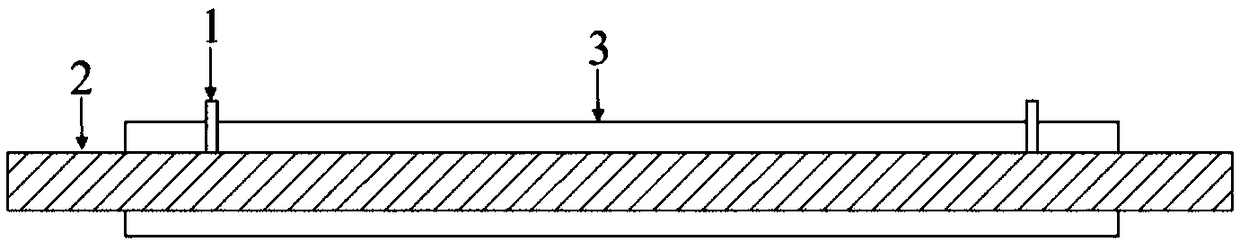

Method used

Image

Examples

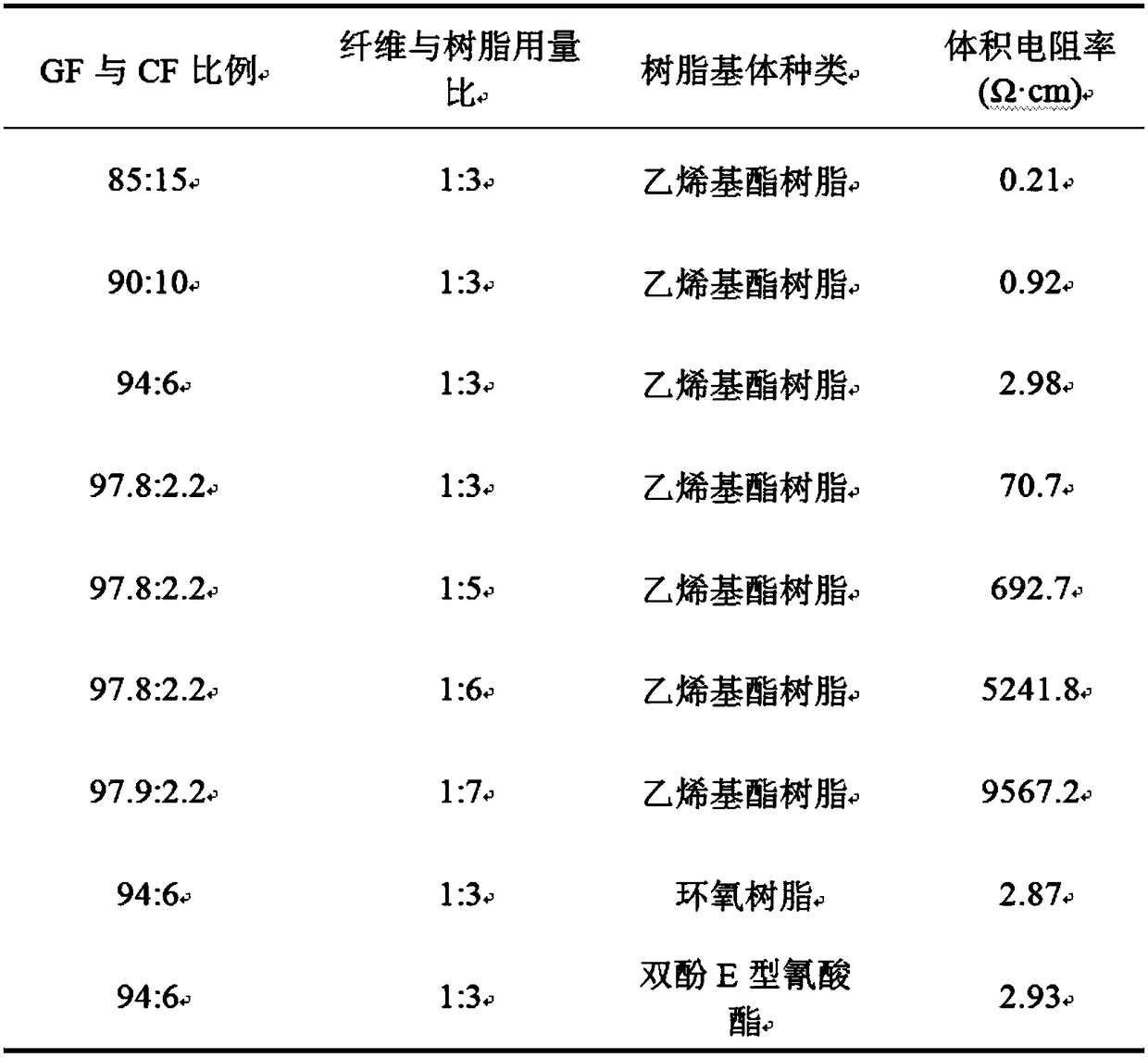

Embodiment 1

[0032] Dry the chopped fibers to be used in the experiment to a constant weight, weigh 170 g of chopped glass fibers with a length of 6 mm, and weigh 30 g of chopped carbon fibers with a length of 6 mm. Add an appropriate amount of water into the beater, start the equipment, add the weighed chopped glass fiber into it, and circulate and disperse for 15 minutes. After 15 minutes, add the weighed chopped carbon fiber and continue to disperse for 7 minutes. After the dispersion is completed, turn off the beater. Transfer the mixture of water and miscellaneous fibers to the suction filtration equipment, and suction filter off most of the water. The obtained hybrid fibers were manually torn into small pieces, and put into a 120°C oven to dry until the weight did not change. Weigh 116.5g vinyl ester resin, add 2.33g methyl ethyl ketone peroxide (initiator) and 1.17g cobalt naphthenate (promoter) to it, and make it mix homogeneously; Add the hybrid fiber prepared before in the resin...

Embodiment 2

[0034]Dry the chopped fibers to be used in the experiment to a constant weight, weigh 180 g of chopped glass fibers with a length of 6 mm, and weigh 20 g of chopped carbon fibers with a length of 6 mm. Add an appropriate amount of water into the beater, start the equipment, add the weighed chopped glass fiber into it, and circulate and disperse for 15 minutes. After 15 minutes, add the weighed chopped carbon fiber and continue to disperse for 7 minutes. After the dispersion is completed, turn off the beater. Transfer the mixture of water and miscellaneous fibers to the suction filtration equipment, and suction filter off most of the water. The obtained hybrid fibers were manually torn into small pieces, and put into a 120°C oven to dry until the weight did not change. Weigh 116.5g vinyl ester resin, add 2.33g methyl ethyl ketone peroxide (initiator) and 1.17g cobalt naphthenate (accelerator) to it, and make it mix homogeneously; Then add the hybrid fiber prepared before in th...

Embodiment 3

[0036] The chopped fibers to be used in the experiment were dried to a constant weight, and 188 g of chopped glass fibers with a length of 6 mm were weighed, and 12 g of chopped carbon fibers with a length of 6 mm were weighed. Add an appropriate amount of water into the beater, start the equipment, add the weighed chopped glass fiber into it, and circulate and disperse for 15 minutes. After 15 minutes, add the weighed chopped carbon fiber and continue to disperse for 7 minutes. After the dispersion is completed, turn off the beater. Transfer the mixture of water and miscellaneous fibers to the suction filtration equipment, and suction filter off most of the water. The obtained hybrid fibers were manually torn into small pieces, and put into a 120°C oven to dry until the weight did not change. Weigh 116.5g vinyl ester resin, add 2.33g methyl ethyl ketone peroxide (initiator) and 1.17g cobalt naphthenate (accelerator) to it, and make it mix homogeneously; Then add the hybrid f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com