Flame retardant polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion and ethyl acrylate, which can be used in coatings, fire-retardant coatings, etc., can solve the problems of polluting the atmospheric environment, the flame retardant effect of inorganic flame retardants and organic phosphorus-based flame retardants needs to be improved, and the cost can be achieved. Low cost, excellent environmental protection, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of flame-retardant type polyacrylate emulsion of the present invention comprises the steps:

[0025] (1) Preparation of phosphorus-containing polyacrylate emulsion

[0026] Dissolve 0.879-0.894g of sodium dodecylsulfonate in 90g of water, 0.235-0.248g of potassium persulfate and 0.0335-0.0345g of sodium bisulfite in 10g of water, transfer to a 500mL three-necked flask, and then add 33.678-33.947g butyl acrylate, 4.299-4.342g ethyl acrylate, 2.520-2.611g acrylic acid, 0.842-0.878g isooctyl acrylate, 0.849-0.888g hydroxyethyl acrylate and 2.520-2.611g 2-hydroxyethyl methyl Acrylate bis(diphenylphosphine) phosphate, heat up to 70-75°C at 300r / min, and keep it warm for 0.5-1h. Then, adjust the temperature of the water bath to 78-80°C, add dropwise 78.421-78.452g butyl acrylate, 9.802-9.947g ethyl acrylate, 5.882-5.984g acrylic acid, 1.962-1.973g isooctyl acrylate, 1.965-1.990g Mixed monomer formed by hydroxyethyl acrylate and 2.520-2.611g 2-hydroxye...

Embodiment 1

[0036] (1) Preparation of phosphorus-containing polyacrylate emulsion

[0037]Dissolve 0.879g sodium dodecylsulfonate in 90g water, dissolve 0.235g potassium persulfate and 0.0335g sodium bisulfite in 10g water respectively, transfer to a 500mL three-necked flask, and then add 33.678g butyl acrylate, 4.299g ethyl acrylate, 2.520g acrylic acid, 0.842g isooctyl acrylate, 0.849g hydroxyethyl acrylate and 2.520g 2-hydroxyethyl methacrylate bis(diphenylphosphine) phosphate, at 300r / min The temperature was raised to 70°C, and the reaction was kept for 0.5h. Then, the temperature of the water bath was adjusted to 78°C, and 78.421g of butyl acrylate, 9.802g of ethyl acrylate, 5.882g of acrylic acid, 1.962g of isooctyl acrylate, 1.965g of hydroxyethyl acrylate and 2.520g of 2-hydroxyethyl methyl 2.091g sodium dodecyl sulfonate and 50g water emulsifier aqueous solution formed by 2.091g sodium dodecyl sulfonate and 50g water, by 0.745g potassium persulfate, 0.1065g sodium bisulfite And...

Embodiment 2

[0043] (1) Preparation of phosphorus-containing polyacrylate emulsion

[0044] Dissolve 0.894g of sodium dodecylsulfonate in 90g of water, 0.248g of potassium persulfate and 0.0345g of sodium bisulfite in 10g of water, transfer them to a 500mL three-necked flask, and then add 33.947g of butyl acrylate, 4.342g ethyl acrylate, 2.611g acrylic acid, 0.878g isooctyl acrylate, 0.888g hydroxyethyl acrylate and 2.611g 2-hydroxyethyl methacrylate bis(diphenylphosphine) phosphate, at 300r / min Raise the temperature to 75°C, and keep the reaction for 1h. Then, the temperature of the water bath was adjusted to 80°C, and 78.452g of butyl acrylate, 9.947g of ethyl acrylate, 5.984g of acrylic acid, 1.973g of isooctyl acrylate, 1.990g of hydroxyethyl acrylate and 2.611g of 2-hydroxyethylmethyl acrylate were added dropwise. 2.109g sodium dodecyl sulfonate and 50g water emulsifier aqueous solution formed by 2.109g sodium dodecyl sulfonate and 50g water, by 0.762g potassium persulfate, 0.1077g s...

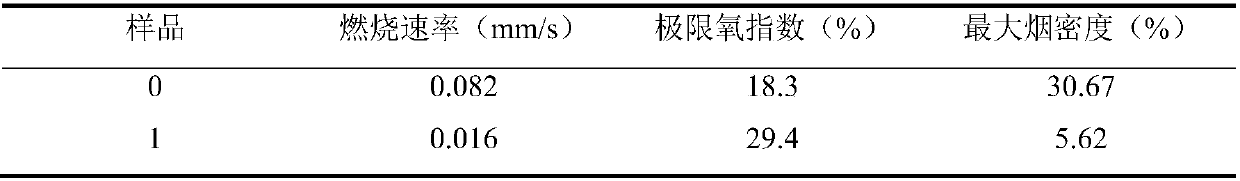

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com