A kind of preparation method of quasicrystal reinforced magnesium matrix composite material

A composite material and reinforced technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of low elongation, low tensile strength, and high specific strength, and achieve advanced technology, accurate and detailed data, and process. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing:

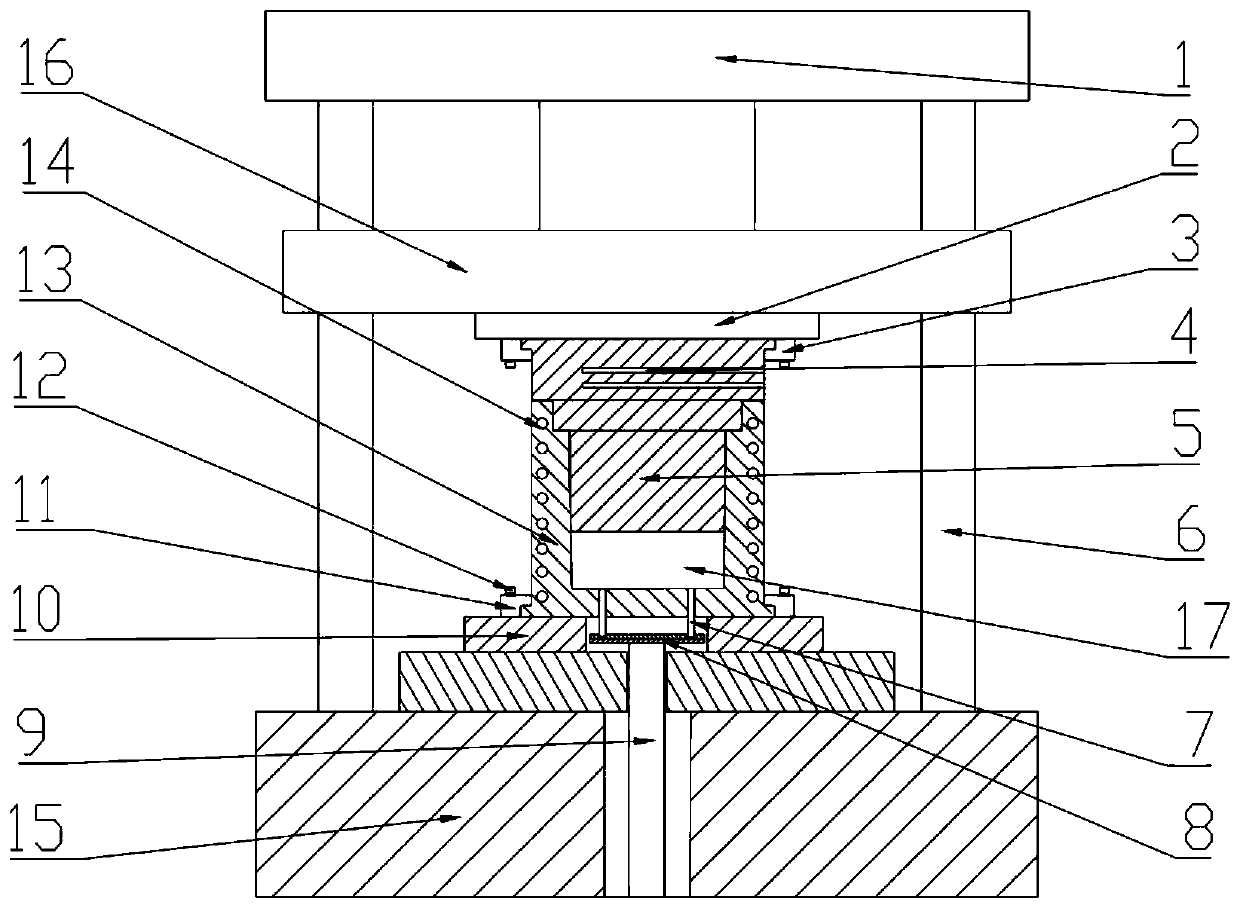

[0064] figure 1 As shown, it is the extrusion state diagram of the quasi-crystal reinforced magnesium-based composite material, and the positions of each part must be correct and operated in sequence.

[0065] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3is the unit of measurement.

[0066] The extrusion of the quasi-crystalline reinforced magnesium-based composite material is carried out on an extruder, and the hydraulic extruder is vertical. The base 15 is at the bottom of the hydraulic extruder 6, and the top seat 16 is at the top of the base 15. Place extrusion die 13 vertically on 10, and be fixed by lower fixing plate 11, lower screw 12; Be provided with heating coil 14 outside die 13; The lower part communicates with the auxiliary oil cylinder 9; the punch 5 is installed on the top base 16, and is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com