Sulfur tail gas purifying device and technology

A tail gas purification device and tail gas purification technology are applied in the fields of sulfur compounds, incinerators, inorganic chemistry, etc., which can solve the problems that the tail gas treatment effect cannot meet the environmental protection requirements, the safety control requirements of the device are high, and the process flow is long, etc., so as to save land occupation , Reduce equipment cost, and the effect of safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

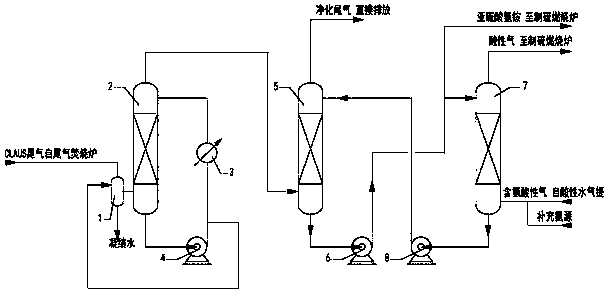

[0045] Such as figure 1 Shown, a kind of sulfur tail gas purifying device comprises tail gas combustion furnace, quenching tower 2, absorption tower 5, regeneration tower 7 and acidic water stripping device connected successively, and described tail gas combustion furnace is connected with the inlet at the bottom of quenching tower 2, and tail gas A liquid collection bag 1 is provided between the combustion furnace and the inlet at the bottom of the quench tower 2 to remove excess water and ensure water balance in the quench tower 2 . The outlet of the quenching water at the bottom of the quenching tower 2 is connected with the inlet at the top of the quenching tower 2 through the circulation pump 4 and the cooler 3 to realize the recycling of the quenching water.

[0046] The top gas outlet at the top of the quench tower 2 is connected to the inlet at the bottom of the absorption tower 5, the lean liquid outlet at the bottom of the regeneration tower 7 is connected to the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com