Method for achieving adjusting and controlling of titanium alloy beta crystal grains obtained through laser additional material manufacturing

A laser additive and titanium alloy technology, which is applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of complex physical process, numerous influencing parameters, and controlled grain morphology, so as to improve the mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

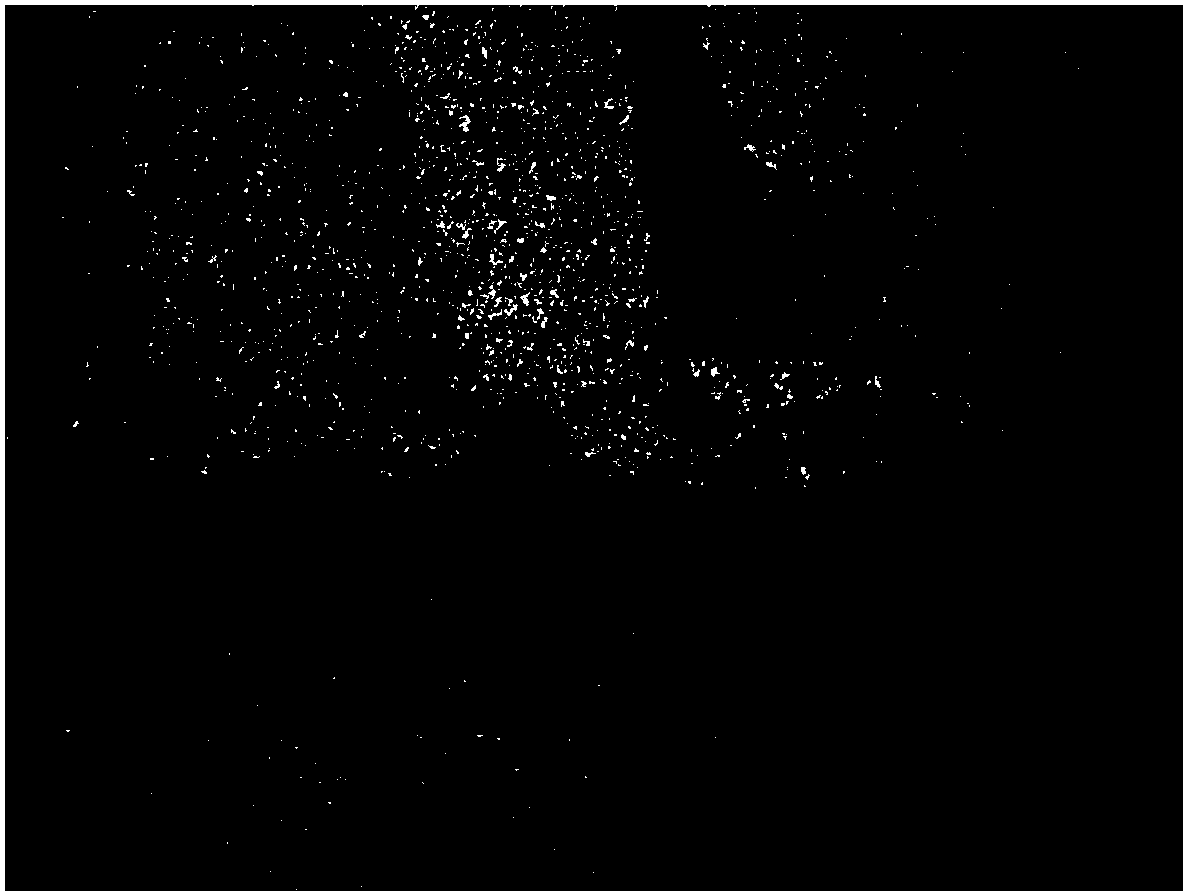

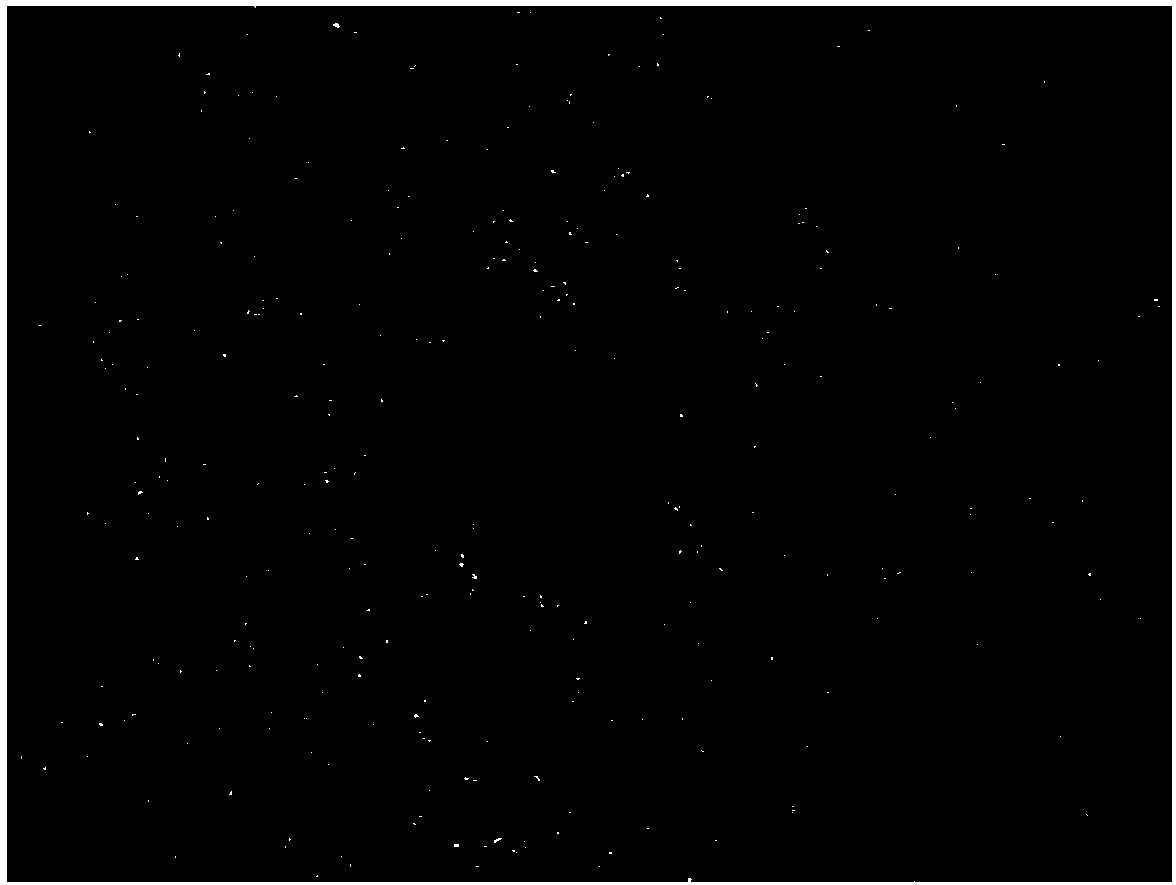

Image

Examples

Embodiment 1

[0019] A method for realizing laser additive manufacturing of titanium alloy β grain regulation, comprising the following steps:

[0020] Step 1: Preliminary optimization of the laser additive manufacturing process window to obtain a preliminary optimized process window, including laser power, spot diameter, scanning speed and powder feeding volume. The optimized parameters are: laser power 300-900W, scanning speed 4 ~12mm / s, powder feeding rate is 6-18g / min, spot diameter is 0.5~2mm;

[0021] Step 2: Randomly select a set of process parameters under the optimization window, use the three-dimensional finite element heat transfer model to calculate the temperature field of the molten pool during the titanium alloy laser additive manufacturing process, and extract the longitudinal temperature of the middle of the molten pool at any moment after the laser is turned on for 1 second. The temperature gradient G1 and cooling rate ξ1 at the 1 / 3 height of the cross-section moving bound...

Embodiment 2

[0027] A method for realizing laser additive manufacturing of titanium alloy β grain regulation, comprising the following steps:

[0028]Step 1: Preliminary optimization of the laser additive manufacturing process window to obtain a preliminary optimized process window, including laser power, spot diameter, scanning speed and powder feeding volume. The optimized parameters are: laser power 300-900W, scanning speed 4 ~12mm / s, powder feeding rate is 6-18g / min, spot diameter is 0.5~2mm;

[0029] Step 2: Randomly select a set of process parameters under the optimization window, use the three-dimensional finite element heat transfer model to calculate the temperature field of the molten pool during the titanium alloy laser additive manufacturing process, and extract the longitudinal temperature of the middle of the molten pool at any moment after the laser is turned on for 1 second. The temperature gradient G1 and cooling rate ξ1 at the 1 / 3 height of the cross-section moving bounda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com