Aquatic product processing wastewater treatment technology and device

A technology for processing waste water and treatment process, which is applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the functions of less engineering examples, more treatment structures, and nitrogen and phosphorus removal. General and other problems, to achieve the effect of strong impact load resistance, inhibition of sludge expansion, and reduction of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

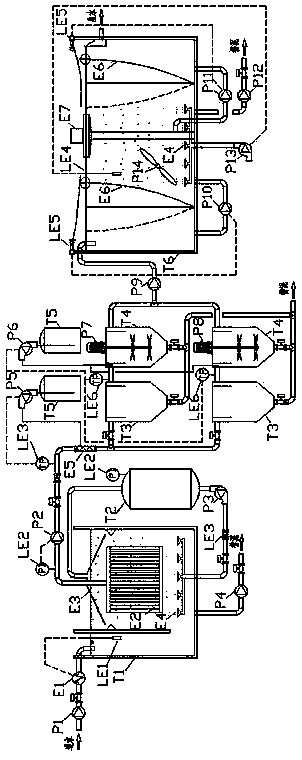

[0048] Below in conjunction with accompanying drawing, invention is further described:

[0049] Such as figure 1 The aquatic processing wastewater treatment device shown is composed of AnMBR processor, secondary phosphorus removal processor and CWSBR processor connected in sequence. The front end of the AnMBR processor is connected to the water inlet pipe to communicate with the aquatic product processing wastewater, and a pipeline heat exchanger is installed on the water inlet pipe. , An MBR processor is equipped with a partition to form an upflow area and a downflow area, the downflow area is connected to the water inlet pipe, the downflow area is connected to the bottom of the upflow area, and an aeration plate is arranged at the bottom of the upflow area, and the top of the aeration plate The membrane module is installed, and the gas collection cover is installed on the top of the membrane module, and the gas collection device is connected to the gas collection device thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com