Treatment method of hexa-phenoxy-cyclotriphosphazene industrial wastewater

A technology of hexaphenoxycyclotriphosphazene and industrial wastewater, which is applied in chemical instruments and methods, preparation of organic compounds, purification of alkali metal halides, etc., can solve the problem of high treatment cost, achieve COD value reduction, and significantly economical Effects of benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

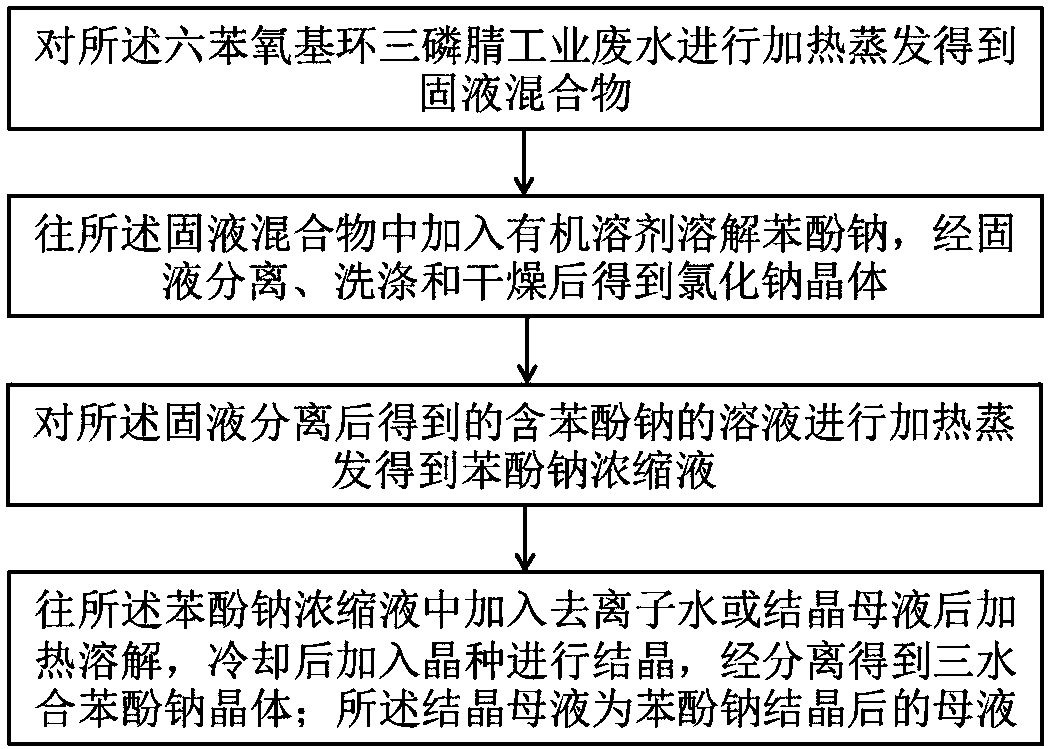

[0028] like figure 1 As shown, the treatment method of hexaphenoxy cyclotriphosphazene industrial wastewater of the present invention comprises the following steps:

[0029] (1) Weigh 300g of waste water and place it in a flask, transfer it to a decompression evaporation device for evaporative crystallization, the degree of vacuum is -90KPa, the initial heating temperature is 65°C, and when the condensate water outlet speed becomes slower and the boiling weakens, the temperature is gradually increased. To 90 ℃, when the waste water evaporates 80% to 90% of its total water, stop heating, take out the solid-liquid mixture after cooling, about 110g;

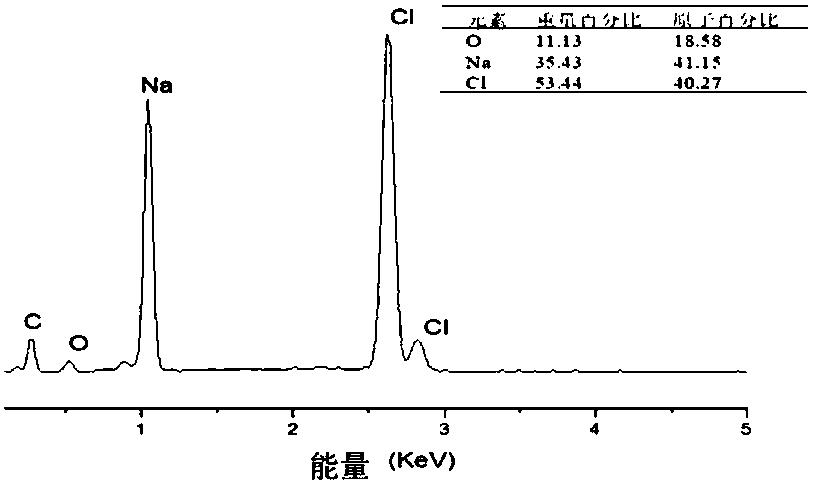

[0030] (2) in above-mentioned solid-liquid mixture, add 150mL ethanol, dissolve sodium phenate, suction filter, and wash with 50mL ethanol, obtain sodium chloride white crystal after drying, quality is 61.4g, the SEM photo of described sodium chloride and energy The spectral analysis results are as figure 2 and 3 shown;

[0031...

Embodiment 2

[0034] (1) Weigh 300g of waste water and place it in a flask, transfer it to a decompression evaporation device for evaporative crystallization, the degree of vacuum is -80KPa, and the initial heating temperature is 65°C. When the speed of condensate water discharge becomes slow and the boiling is weakened, the temperature is gradually increased. To 90 ℃, when the waste water evaporates 80% to 90% of its total water, stop heating, take out the solid-liquid mixture after cooling, about 110g;

[0035] (2) adding 150 mL of methanol to the above-mentioned solid-liquid mixture, dissolving sodium phenate, suction filtration, and washing with 50 mL of methanol, after drying, a white crystal of sodium chloride was obtained, the quality was 60.2 g, and the purity was 98%;

[0036] (3) the above-mentioned filtrate containing sodium phenolate is transferred into the decompression evaporation device to carry out evaporative concentration, vacuum tightness is -80~-90Kpa, initial heating tem...

Embodiment 3

[0039] Adopt the same steps as steps (1) to (3) in Example 1 to prepare the crude sodium phenolate, and measure the mass fraction of sodium phenolate in the crude sodium phenolate by ultraviolet spectrophotometry at a wavelength of 290 nm to be 55%, take 30 g The crude sodium phenate was added with 9 mL of deionized water, heated to 70 °C to dissolve, and when it was cooled to 30 to 35 °C at room temperature, sodium phenolate trihydrate seeds were added, and crystals began to separate out. After 30 minutes, transfer to a refrigerator for crystallization at -5 °C , 12h later, prismatic white sodium phenolate crystals were obtained, and the composition of the crystals was sodium phenolate trihydrate, the mass was 16.3g, and the purity was 97% by ultraviolet spectroscopic analysis and detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com