Purification crystallization process and system for extracting beta-alanine from enzymatic conversion liquid

A crystallization system and enzyme conversion technology, applied in the field of bioengineering, can solve the problems of filter membrane pollution, low adsorption effect, affecting the purity and yield of β-alanine, etc., and achieve the effect of improving adsorption and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

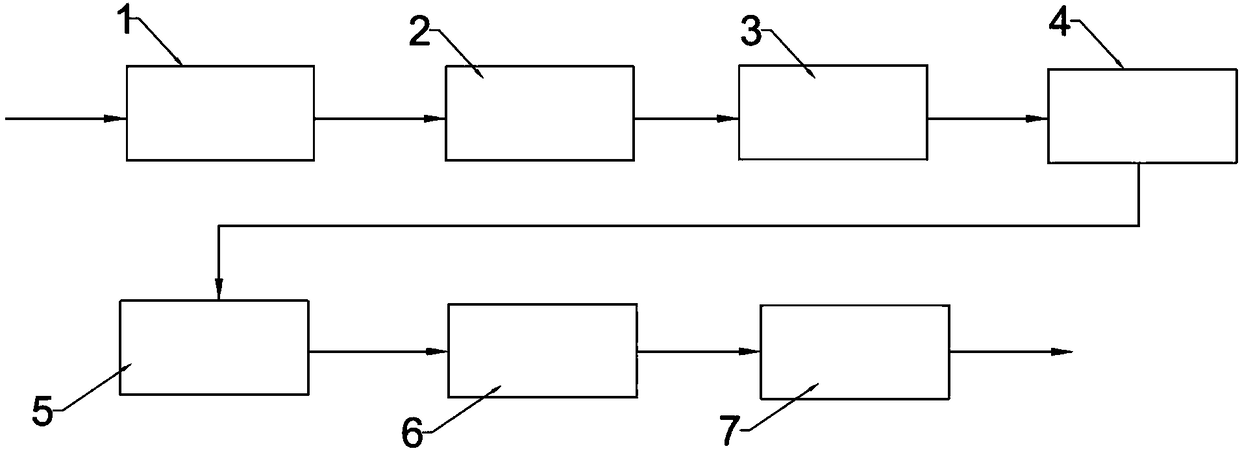

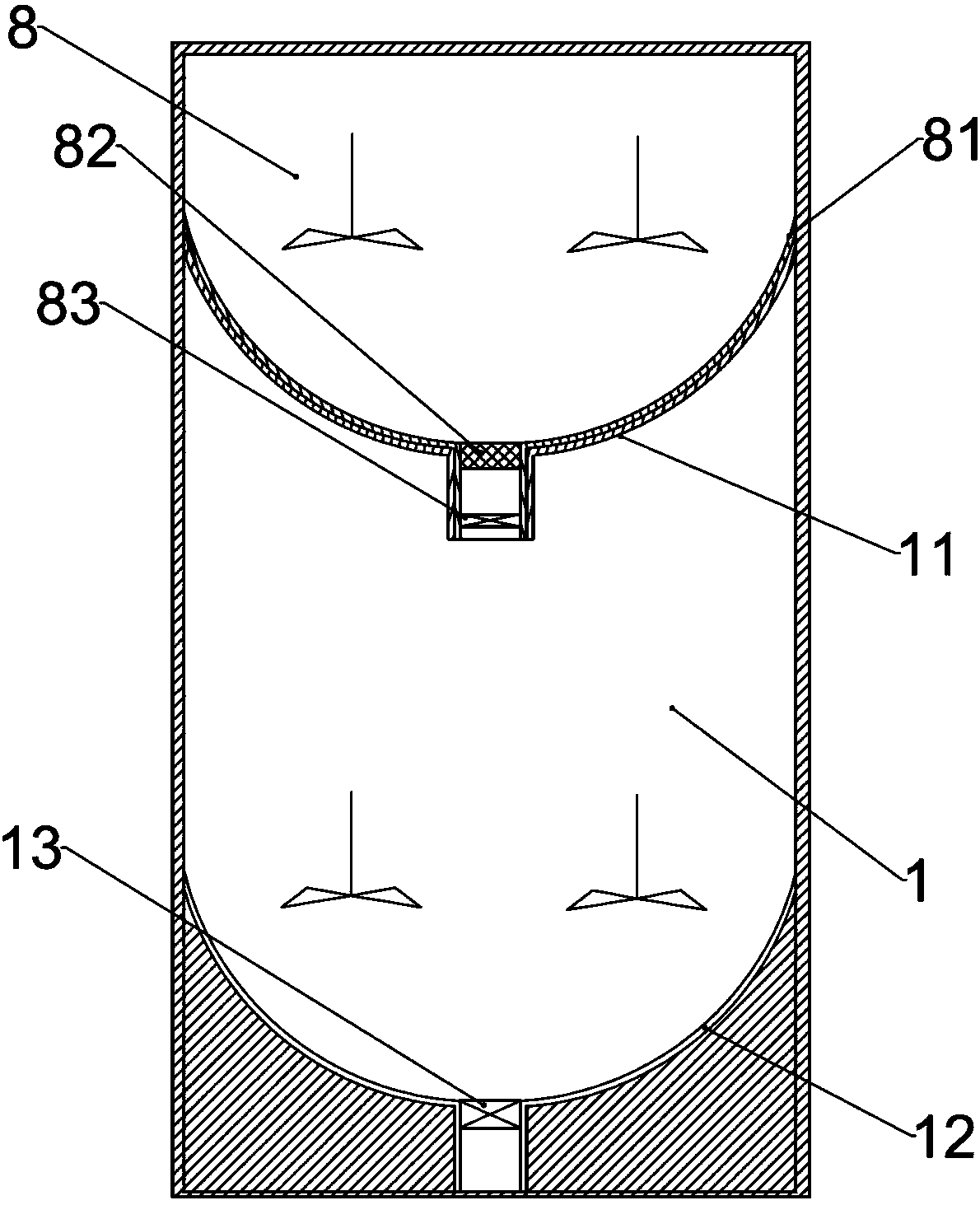

[0041] The purification and crystallization system for extracting β-alanine from the enzyme conversion solution provided in this example, such as figure 1 As shown, it includes: a decolorization treatment device 1, a chamber is provided in the decolorization treatment device 1, and a liquid inlet and an activated carbon powder dosing port of the decolorization treatment device 1 are arranged on the chamber, containing β- The enzymatic conversion liquid of alanine enters the chamber through the liquid inlet, and the activated carbon powder is used to decolorize the enzymatic conversion liquid, and a first pH adjustment device is arranged in the chamber; The decolorization treatment device 1 adopts a stirring tank, and a stirring device is arranged in the stirring tank, and the stirring tank is provided with a heating device, which is suitable for regulating the temperature in the tank, and the first pH adjusting device includes an acid liquid dripping pipe, Alkali dripping tube...

Embodiment 2

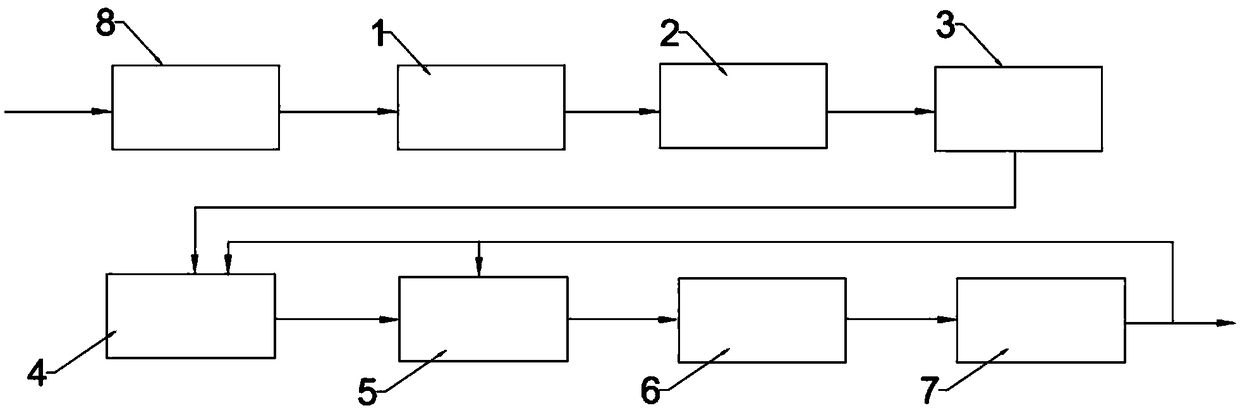

[0048] The purification and crystallization system for extracting β-alanine from the enzyme conversion solution provided in this example, such as figure 2 As shown, it includes: an adsorption device 8, which can use diatomite particles to perform adsorption treatment on the enzyme conversion solution containing β-alanine.

[0049] The decolorization treatment device 1 is provided with a chamber in the decolorization treatment device 1, and the liquid inlet and the activated carbon powder feeding port of the decolorization treatment device 1 are arranged on the chamber, and the enzyme containing β-alanine The conversion liquid enters the chamber through the liquid inlet, and decolorizes the enzyme conversion liquid by using activated carbon powder, and a first pH adjustment device is arranged in the chamber for adjusting The pH value of the enzyme conversion solution; the decolorization treatment device 1 described in the present embodiment adopts a stirred tank, and a stirrin...

Embodiment 3

[0059] The purification and crystallization system for extracting β-alanine from the enzyme conversion solution provided in this example is the same as that in Example 2.

[0060] The diatomite particles used in this example are diatomite particles modified by cationic surfactants. In this embodiment, the method for modifying the diatomite particles is as follows: weigh a certain amount of diatomite particles with a particle size range of 0.8-1.5mm, and then weigh a certain amount of cationic surfactant. The cationic surfactant used in the embodiment is cetyltrimethylammonium bromide, the consumption of described cationic surfactant and the consumption of described diatomaceous earth particle are 1:25 in mass ratio, add pure water Afterwards, heat to 75° C., and place for 4 hours in a state of heat preservation and stirring to complete the modification reaction. Wherein after adding pure water, the concentration of the cationic surfactant in the pure water is 1g / L. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com