Preparation method of Chinese honeylocust fruit extracting solution

A kind of saponin extract and technology of saponin, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as complicated process, use of organic solvents that do not conform to green technology, and large investment in equipment , to achieve the effect of simple operation, solving the problem of poor decolorization efficiency and outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

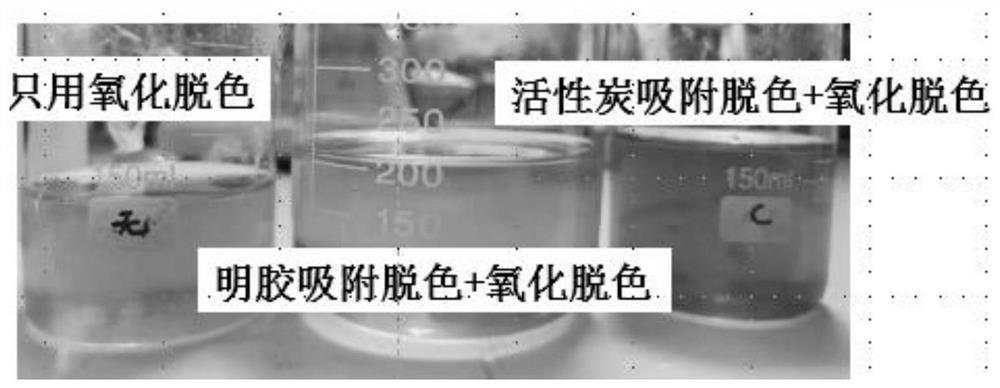

Embodiment 1

[0026] After cleaning the whole body of fresh saponin pods, dry them at 50°C to constant weight, subtract the two ends of the saponin pods, crush them in sections, and remove the seeds to obtain the crushed saponin pod bodies without seeds. Weigh 100g of the saponin pod bodies Add deionized water at a ratio of 1:10 (g / mL), extract at 70°C for 2 hours at a stirring rate of 20rpm, filter and separate the filter residue and filtrate, and filter with a Buchner funnel and rapid qualitative filter paper at 1 atmosphere. , obtain 1000mL thick saponins extract, test the concentration of solids (note: solid content hereinafter obtains with CL, and solids refer to the material except moisture in the filtrate), the concentration CL of recorded solids is 3.8%, That is, the mass of the solid is 38 g.

[0027] Weigh gelatin according to the ratio of 70% of the solid matter in the crude saponin extract (Shanghai National Pharmaceutical Co., Ltd., product number 10010328), first soak the gela...

Embodiment 2

[0040] After cleaning the whole body of fresh saponin pods, dry them at 50°C to constant weight, subtract the two ends of the saponin pods, crush them in sections, and remove the seeds to obtain the crushed saponin pod bodies without seeds. Weigh 100g of the saponin pod bodies Add deionized water at a ratio of 1:10 (g / mL), extract at 40°C for 3 hours at a stirring rate of 200rpm, filter and separate the filter residue and filtrate, and filter with a Buchner funnel and rapid qualitative filter paper at 1 atmosphere. , to obtain 1000mL thick saponin extract, test the concentration of solids (note: the solid content is obtained with CL hereinafter, and solids refer to the substances other than moisture in the filtrate).

[0041] Weigh the gelatin according to the ratio of 50% of the solid matter in the crude saponin extract, first soak the gelatin in deionized water for 2 hours, add it to the crude saponin extract, perform adsorption decolorization treatment, and stir at room temp...

Embodiment 3

[0046] After cleaning the whole body of fresh saponin pods, dry them at 50°C to constant weight, subtract the two ends of the saponin pods, crush them in sections, and remove the seeds to obtain the crushed saponin pod bodies without seeds. Weigh 100g of the saponin pod bodies Add deionized water at a ratio of 1:10 (g / mL), extract at 80°C for 1 hour at a stirring rate of 10 rpm, filter and separate the filter residue and filtrate, and filter with a Buchner funnel and rapid qualitative filter paper at 1 atmosphere. , to obtain 1000mL thick saponin extract, test the concentration of solids (note: the solid content is obtained with CL hereinafter, and solids refer to the substances other than moisture in the filtrate).

[0047] Weigh the gelatin according to the ratio of 90% of the solid matter in the crude saponin extract, first soak the gelatin in deionized water for 0.5h, add it into the thick saponin extract, and carry out adsorption decolorization treatment at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com