Flame-retardant and antistatic chlorinated polyethylene composite material applied to gas drainage pipeline and preparation method thereof

A chlorinated polyethylene, flame retardant and antistatic technology, applied in the field of plastic modification, can solve the problems of affecting the health of workers, difficulty in improving flame retardancy, poor antistatic and flame retardancy, etc., and achieve excellent antistatic performance, resistance Good flammability and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

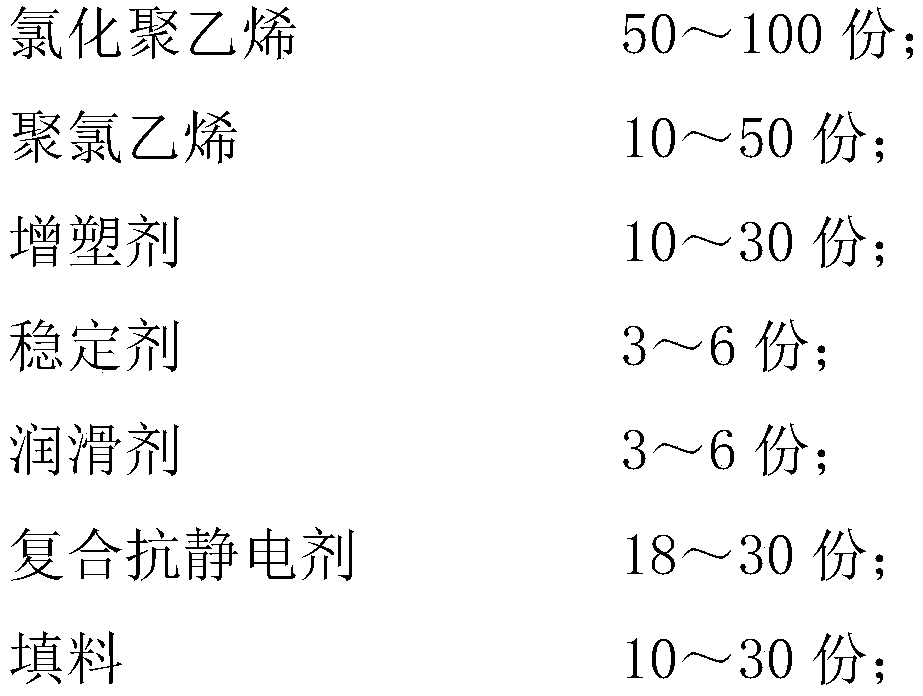

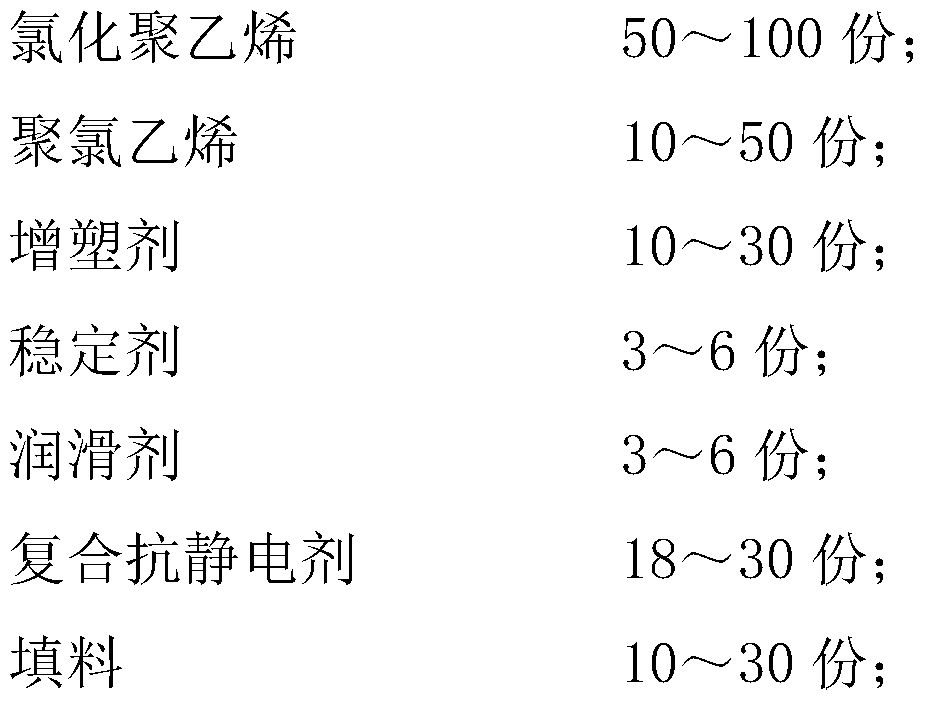

Method used

Image

Examples

Embodiment 1

[0029] Parts by weight are 70 parts by weight of chlorinated polyethylene material, parts by weight are 30 parts by weight of polyvinyl chloride resin, parts by weight are 2.5 parts by weight of lead sulfate tribasic, parts by weight are 1.5 parts by weight of lead stearate, parts by weight are 2 parts by weight of paraffin, 1.5 parts by weight of OPE (AC316A, Honeywell), 4 parts by weight of antistatic agent SH105, 6 parts by weight of AEO-5, 5 parts by weight of special conductive carbon black ( HG-IP), parts by weight are 5 parts by weight of conductive carbon black (2650) and parts by weight are 25 parts by weight of carbon black (N330), weighed according to the number of parts by weight, pour into high-speed mixer, start mixing machine, high-speed stirring, when the material temperature reaches 85°C, add 13 parts by weight of DOP, continue high-speed stirring, when the material temperature reaches 100°C, switch to low-speed stirring, when the material temperature reaches 1...

Embodiment 2

[0031] Parts by weight are 60 parts by weight of chlorinated polyethylene material, parts by weight are 40 parts by weight of polyvinyl chloride resin, parts by weight are 2.5 parts by weight of lead sulfate tribasic, parts by weight are 1.5 parts by weight of lead dibasic phosphite, and parts by weight are Parts are 1.5 parts of lead stearate, parts by weight are 2 parts of paraffin wax, parts by weight are 1.5 parts of OPE (AC316A, Honeywell), parts by weight are 6 parts of antistatic agent SH105, parts by weight are 6 parts of AEO- 5. Parts by weight are 7 parts by weight of special conductive carbon black (HG-IP), parts by weight are 7 parts by weight of conductive carbon black (2650) and parts by weight are 30 parts by weight of carbon black (N330), which are called according to the parts by weight The amount is good, pour into the high-speed mixer, start the mixer, and stir at a high speed. When the temperature of the material reaches 85°C, add 20 parts by weight of DOP a...

Embodiment 3

[0033]Parts by weight are 50 parts by weight of chlorinated polyethylene material, parts by weight are 50 parts by weight of polyvinyl chloride resin, parts by weight are 4.5 parts of rare earth composite stabilizer, parts by weight are 1 part of lead stearate, parts by weight are 1 part of paraffin, parts by weight are 0.8 parts of OPE (AC316A, Honeywell), parts by weight are 8 parts of antistatic agent SH105, parts by weight are 6 parts of AEO-5, parts by weight are 7 parts of special conductive carbon black (HG -IP), parts by weight are 7 parts of conductive carbon black (2650) and parts by weight of 30 parts of carbon black (N330), weighed according to the parts by weight, pour into high-speed mixer, start the mixer , high-speed stirring, when the material temperature reaches 85°C, add 11 parts by weight of DOP and 5 parts by weight of DOA, continue high-speed stirring, when the material temperature reaches 100°C, switch to low-speed stirring, and the material temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com