Water-based uv coating with temporary protection effect and its preparation method and application

A temporary protection, water-based technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of wasting time, cost, energy consumption, and low production capacity, and achieve excellent wear resistance, improve product yield, and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

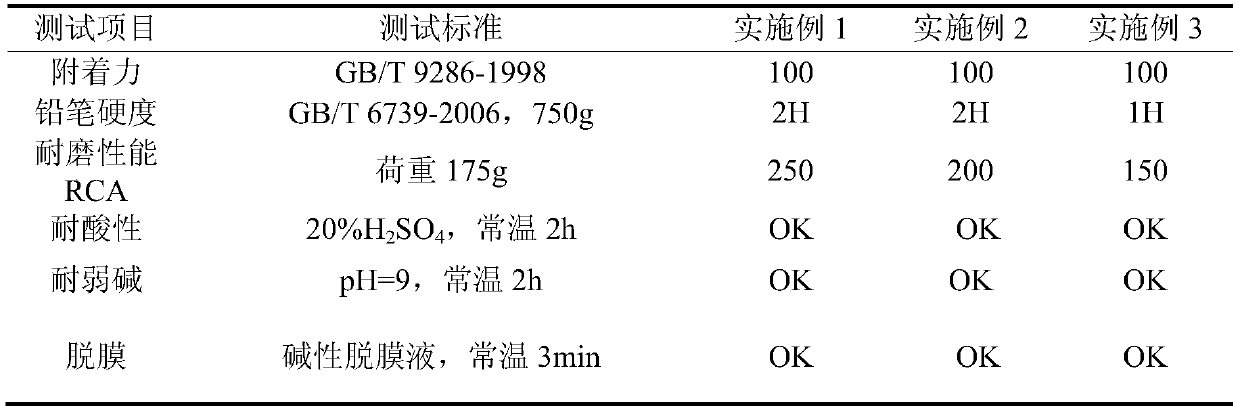

Examples

Embodiment 1

[0060] The present embodiment provides a kind of water-based UV paint with temporary protective effect, comprising the following components in mass percent: 58% of carboxy-modified water-soluble polyurethane acrylate, 8% of ethoxylated trimethylolpropane triacrylate, Dipropylene glycol methyl ether 5%, N,N-dimethylethanolamine 0.2%, water-based wetting agent 0.8%, water-based defoamer 0.3%, photoinitiator 2.5%, adhesion promoter 1%, matting powder 3%, Water 21.2%; wherein, the photoinitiator is a mixture of 1-hydroxycyclohexyl phenyl ketone, benzophenone and 2,4,6-trimethylbenzoyl phenyl phosphonic acid ethyl ester.

[0061] The above-mentioned water-based UV paint preparation method with temporary protective effect may further comprise the steps:

[0062] While dispersing, add the above water-based polyurethane acrylate resin, ethoxylated trimethylolpropane triacrylate, dipropylene glycol methyl ether, N,N-dimethylethanolamine, water-based wetting agent, water-based defoamer,...

Embodiment 2

[0066] The present embodiment provides a kind of water-based UV paint with temporary protective effect, comprising the following components in mass percent: 55% of carboxy-modified water-soluble polyurethane acrylate, 11% of ethoxylated trimethylolpropane triacrylate, Dipropylene glycol methyl ether 5%, N,N-dimethylethanolamine 0.2%, water-based wetting agent 0.8%, water-based defoamer 0.3%, photoinitiator 2.5%, adhesion promoter 1%, matting powder 3%, Water 21.2%; wherein, the photoinitiator is a mixture of 1-hydroxycyclohexyl phenyl ketone, benzophenone and 2,4,6-trimethylbenzoyl phenyl phosphonic acid ethyl ester.

[0067] The preparation method of the water-based UV paint with temporary protective effect in this embodiment and the application on the metal substrate are the same as in Example 1.

Embodiment 3

[0069]The present embodiment provides a kind of water-based UV paint with temporary protective effect, comprising the following components in mass percentage: 58% of carboxy-modified water-soluble polyurethane acrylate, 8% of propoxylated glycerin triacrylate, dipropylene glycol methyl ether 5%, N,N-dimethylethanolamine 0.2%, water-based wetting agent 0.8%, water-based defoamer 0.3%, photoinitiator 1.5%, adhesion promoter 1%, matting powder 3%, water 22.2%; Wherein, the photoinitiator is 1-hydroxycyclohexyl phenyl ketone, benzophenone and ethyl 2,4,6-trimethylbenzoyl phenyl phosphonate.

[0070] The preparation method of the water-based UV paint with temporary protective effect in this embodiment and the application on the metal substrate are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com