A kind of dust suppressant and its preparation method and application in coal transportation

A technology of dust suppressant and preservative, which is applied in the field of dust suppressant and its preparation, can solve the problems of poor comprehensive performance and achieve the effects of low cost, excellent comprehensive performance and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055]The present invention also provides the preparation method of the above-mentioned dust suppressant, comprising the following steps: dissolving polyvinyl alcohol, alginate and water-soluble cellulose in water according to metering, then adding polymer emulsion, mixing, and finally Add emulsifiers and preservatives, mix well, and get ready.

[0056] The solubility of polyvinyl alcohol in water is related to its degree of alcoholysis: when the degree of alcoholysis is 86% to 89%, the water solubility is the best, and it can be dissolved quickly in cold water and hot water; the degree of alcoholysis is 90% In the above cases, in order to completely dissolve, it generally needs to be heated to 60-70°C; when the degree of alcoholysis exceeds 99%, it can only be dissolved in hot water above 95°C.

[0057] The present invention provides a dust suppressant mainly used in coal transportation by adopting specific components and proportions, which can meet the dust suppression effec...

Embodiment 1

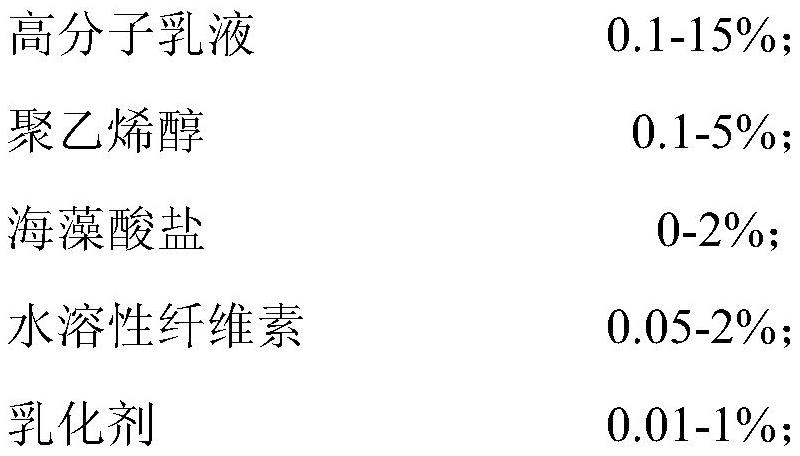

[0074] By weight, the dust suppressant of this embodiment comprises the following components:

[0075]

[0076] Preparation:

[0077] According to measurement, take polyvinyl alcohol (PVA1788), sodium alginate (500-550mPa·s), water-soluble cellulose (hydroxypropyl methylcellulose), dissolve in water, and then add polymer emulsion (water-based polyurethane dispersion ), mix well, and finally add emulsifier (tetradecyltrimethylammonium bromide), preservative (potassium sorbate), mix well, and obtain dust suppressant.

Embodiment 2

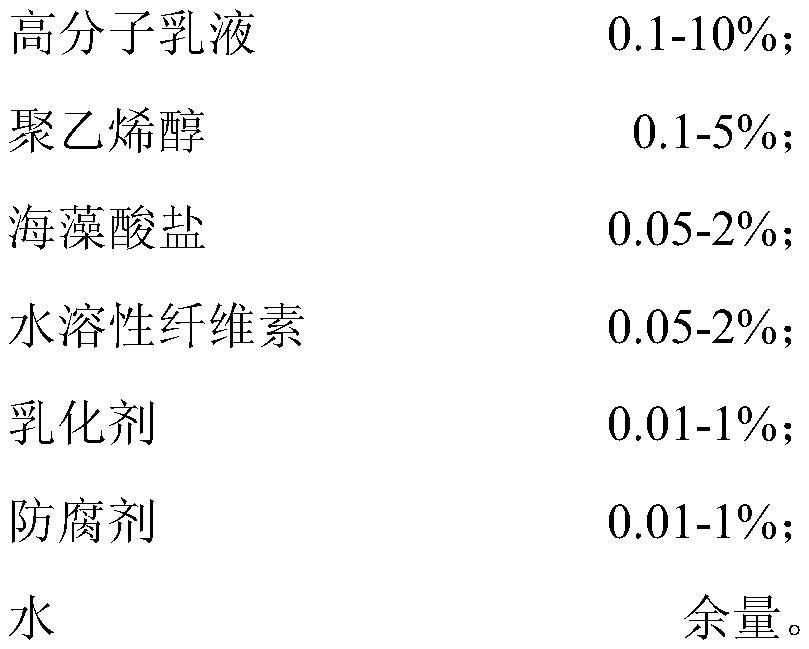

[0079] By weight, the dust suppressant of this embodiment comprises the following components:

[0080]

[0081]

[0082] Preparation:

[0083] Measured, take polyvinyl alcohol (PVA1788), sodium alginate (500-550mPa·s), water-soluble cellulose (carboxymethyl cellulose), dissolve in water, then add polymer emulsion (styrene-acrylic emulsion), mix Mix well, and finally add emulsifier (hexadecyltrimethylammonium bromide), preservative (potassium sorbate), and mix well to obtain dust suppressant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com