A crude gas upgrading process

A crude gas upgrading technology, which is applied in the field of crude gas upgrading equipment, crude gas upgrading process, and DRI preparation equipment, can solve the problems of huge investment, high loss, long and complicated process, etc., and achieve short process, Small investment, good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

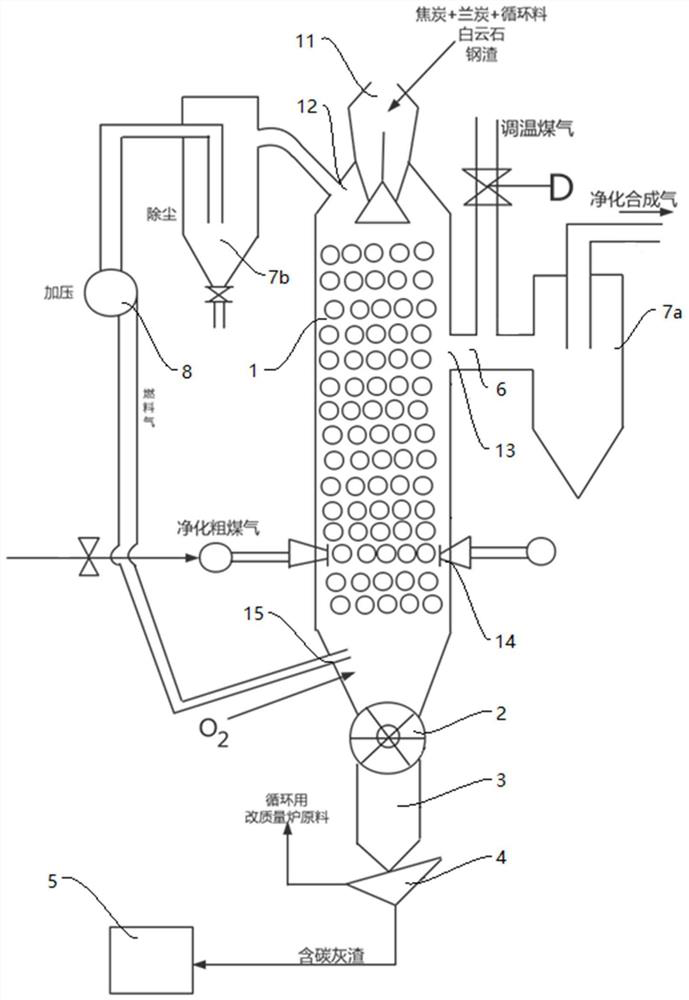

[0033] like figure 1 As shown, the reforming furnace 1 has a certain height, and the inner space of the reforming furnace 1 is the reforming working space. The top of the reforming furnace 1 includes a charging inlet 11, through which the charging of the reforming furnace is filled into the reforming workspace, including 35%wt of coke, 35%wt blue carbon, 20%wt of dolomite and 10%wt of Converter slag. The particle size of the reforming furnace charge is 50mm, and there are a lot of gaps between the particles, which can pass through the gas.

[0034] When starting the furnace, hot air above 700°C is introduced first, and the coke in the reforming furnace 1 starts to burn at this temperature. The air induction duct can lead to the combustion port 15 at the lower part of the reforming furnace 1 . Then the combustion-supporting oxygen is introduced to make the combustion more intense, and the temperature rises to about 1200°C. A large amount of CO is produced during combustion ...

Embodiment 2

[0044] There are two reforming furnaces 1, the top gas of the two reforming furnaces 1 returns to one place, and then performs dust removal and water washing in the second cyclone dust collector 7b, and reaches a three-way valve after being pressurized by the booster pump 8; After dust removal, water washing and pressurization, they can be collected at the three-way valve. The three-way valve can selectively lead the furnace top gas back to the combustion port 15 of one of the two reforming furnaces 1 .

[0045] One of the two reforming furnaces 1 is first heated to 1250° C. for reforming, and top gas is discharged during the reforming process. The exhausted furnace top gas is led through the three-way valve into another reforming furnace 1, that is, the combustion port 15 of the preceding heating furnace, and is burned with the help of combustion-supporting oxygen to increase the furnace temperature of the preceding heating furnace.

[0046] The reforming furnace charges in ...

Embodiment 3

[0050] As in Example 2, the purified synthesis gas is led to the shaft furnace where iron ore or oxidized pellets are placed, and after reflection, direct reduced iron and shaft furnace top gas are obtained.

[0051] The top gas of the shaft furnace is heat-exchanged and dust-removed, then mixed with the upgraded gas as temperature-adjusted gas, and purified synthesis gas is obtained after dust removal. Shaft furnace gas is recycled to reduce waste. The cost is reduced, the structure of the device is compact, and the process for preparing direct reduced iron is short.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com