A kind of preparation method of colored polyester yarn

A technology of colored polyester and polyester yarn, which is used in the melting of filament raw materials, filament forming treatment, feeding solution to spinnerets, etc. Color difference, color fastness and stretchability, etc., to achieve the effect of saving pollution control costs, reducing dyeing costs, and small color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

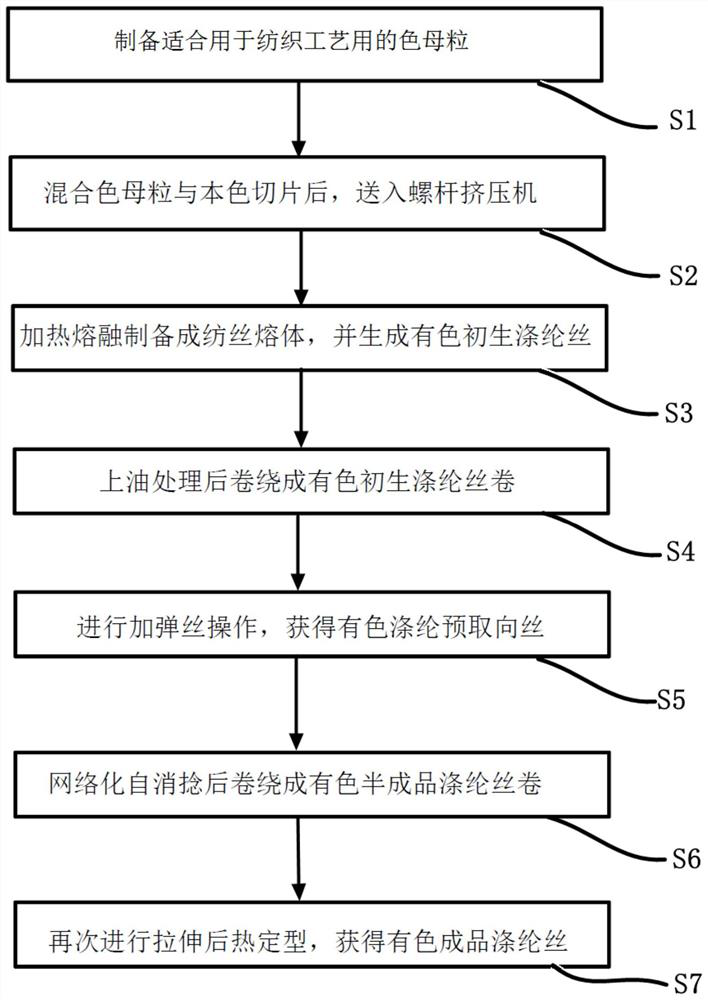

[0029] In this embodiment, the preparation method of the colored polyester yarn involved in the present invention comprises the following steps:

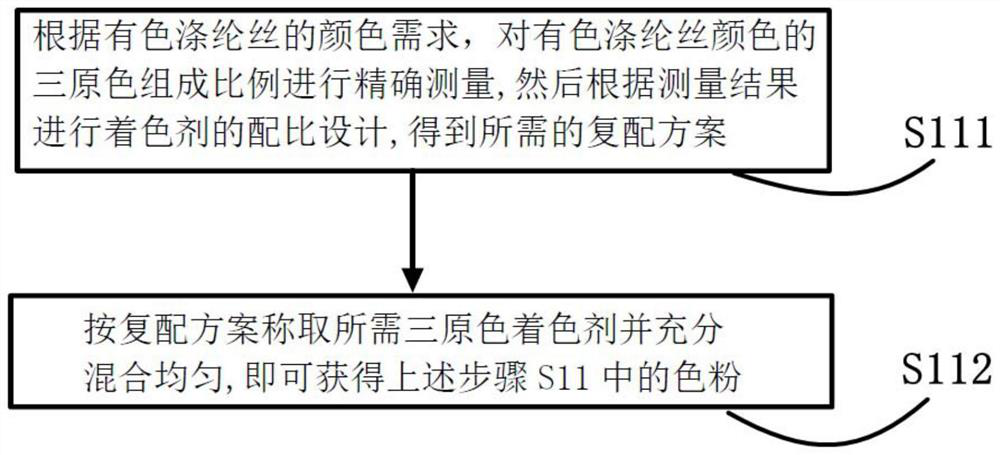

[0030] S1. Prepare color masterbatch suitable for textile technology. Wherein, the preparation steps of above-mentioned masterbatch are as follows:

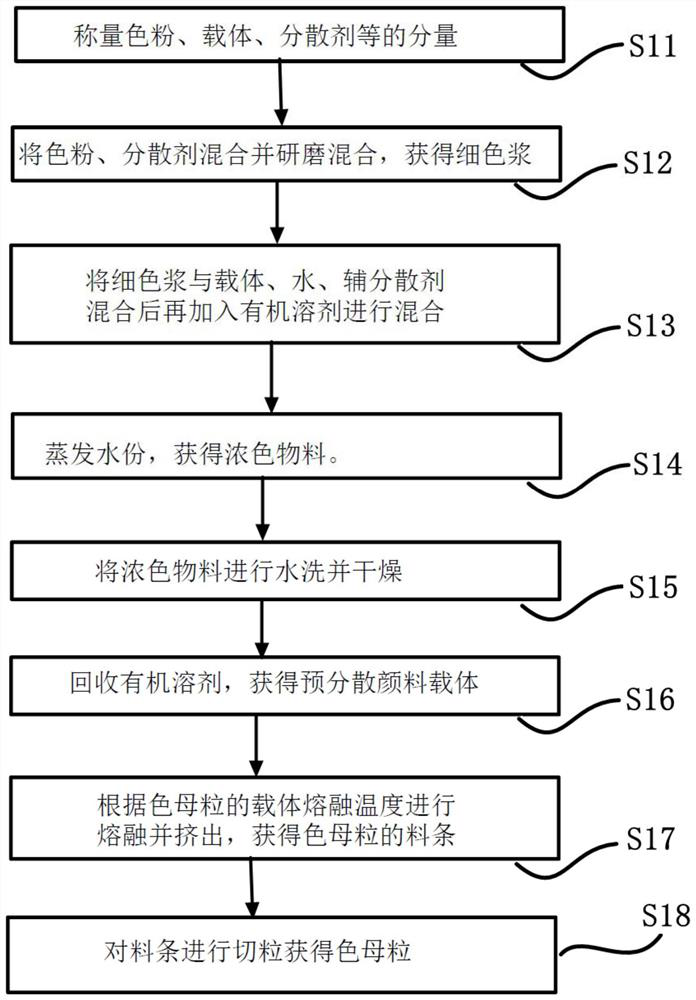

[0031]S11. Weigh the components of toner, carrier, dispersant, etc. according to the process requirements. Wherein, the amount of the above-mentioned toner accounts for about 15% to 60% of the mass of the masterbatch. Color powder can choose organic pigment or inorganic pigment. Commonly used organic pigments are: phthalocyanine red, phthalocyanine blue, phthalocyanine green, light fast red, macromolecular red, macromolecular yellow, permanent yellow, permanent purple, azo red, etc. Commonly used inorganic pigments are: cadmium Red, Cadmium Yellow, Titanium Dioxide, Carbon Black, Iron Oxide Red, Iron Oxide Yellow, etc. The added amount of the above-mentioned carrier is about 30% to...

Embodiment 1

[0055] Weigh the toner accounting for 15% of the mass of the masterbatch, the carrier accounting for 70% of the mass of the masterbatch, the main dispersant accounting for 10% of the mass of the masterbatch, and the auxiliary dispersing agent accounting for 5% of the mass of the masterbatch, and add an appropriate amount of water for grinding Mix to obtain a fine color paste. Then mix the fine color paste with the carrier, water and auxiliary dispersant into the phase inversion tank, then add an appropriate amount of organic solvent for mixing, evaporate the water in it to obtain a thick color material, wash the thick color material with water and put it in the Dry in an oven at 90°C for 5h. The organic solvent in the dried concentrated color material is recovered to obtain a pre-dispersed pigment carrier. Melt and extrude according to the carrier melting temperature of the color masterbatch to obtain a strip of the color masterbatch. Cut the strips into pellets to obtain ma...

Embodiment 2

[0061]Weigh the toner accounting for 60% of the mass of the masterbatch, the carrier accounting for 30% of the mass of the masterbatch, and the main dispersant accounting for 10% of the mass of the masterbatch, add an appropriate amount of water for grinding and mixing, and obtain a fine color paste. Then mix the fine color paste with the carrier, water and auxiliary dispersant into the phase inversion tank, then add an appropriate amount of organic solvent for mixing, evaporate the water in it to obtain a thick color material, wash the thick color material with water and put it in the Dry in an oven at 160°C for 3h. The organic solvent in the dried concentrated color material is recovered to obtain a pre-dispersed pigment carrier. Melt and extrude according to the carrier melting temperature of the color masterbatch to obtain a strip of the color masterbatch. Cut the strips into pellets to obtain masterbatches.

[0062] After the color masterbatch and the natural color chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| filterability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com