Antimony selenide thin film preparation method and device

A thin film preparation and antimony selenide technology, which is applied in the field of preparation of antimony selenide photoelectric thin film materials, can solve the problems of increasing production links and production costs, poor post-selenization selenium supplementation process effect, unfriendly environment, etc., and achieves favorable Production technology, reduction of preparation and production costs, environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

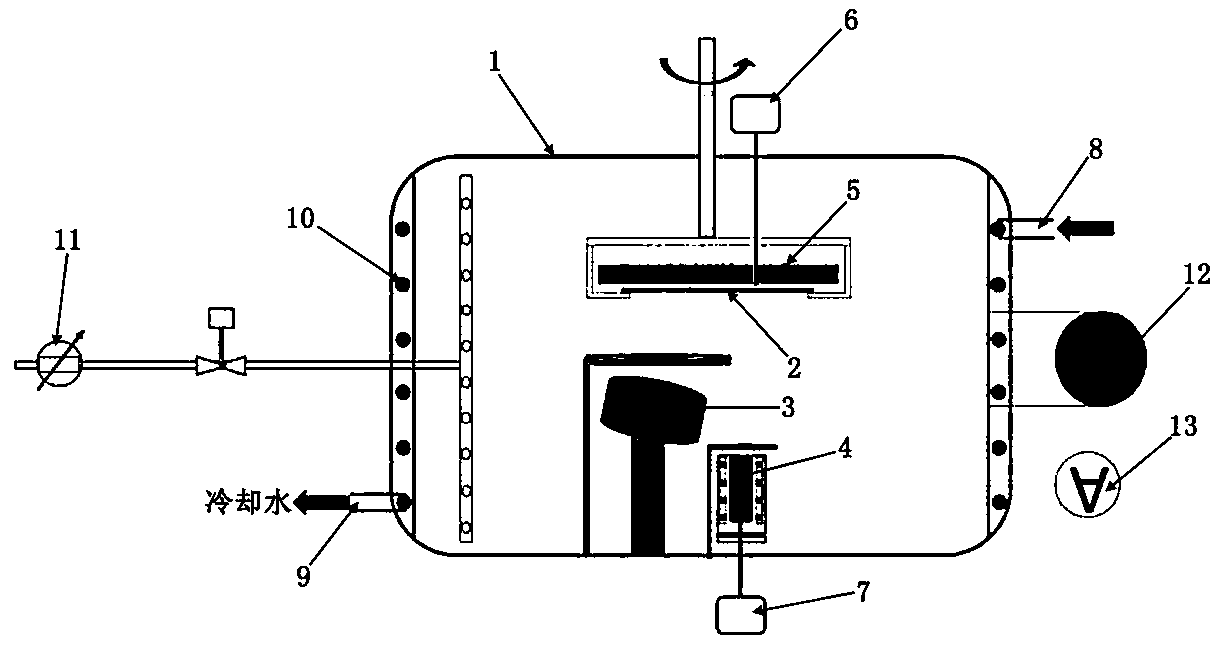

[0022] Example 1 Antimony Selenide Film Online Selenium Compensation Device

[0023] The device structure of the present invention is as figure 1 As shown, the growth chamber 1 is provided with a sputtering system and a thermal evaporation system respectively.

[0024] The sputtering system is provided with a rotating substrate table with a heating wire 5 in the growth chamber 1, a radio frequency magnetron sputtering target table is provided under the substrate table, and a cooling system is provided on the peripheral wall of the growth chamber 1, for The growth chamber 1 is fed with an intake system of inert Ar gas, a vacuum system and a pressure detection system. The rotating substrate table is used to place the substrate 2 to be sputtered, and the heating wire 5 is used to heat the substrate 2 placed on the rotating substrate table, and monitor the temperature of the substrate 2 in real time through the first thermometer 6 . The radio frequency magnetron sputtering targe...

Embodiment 2

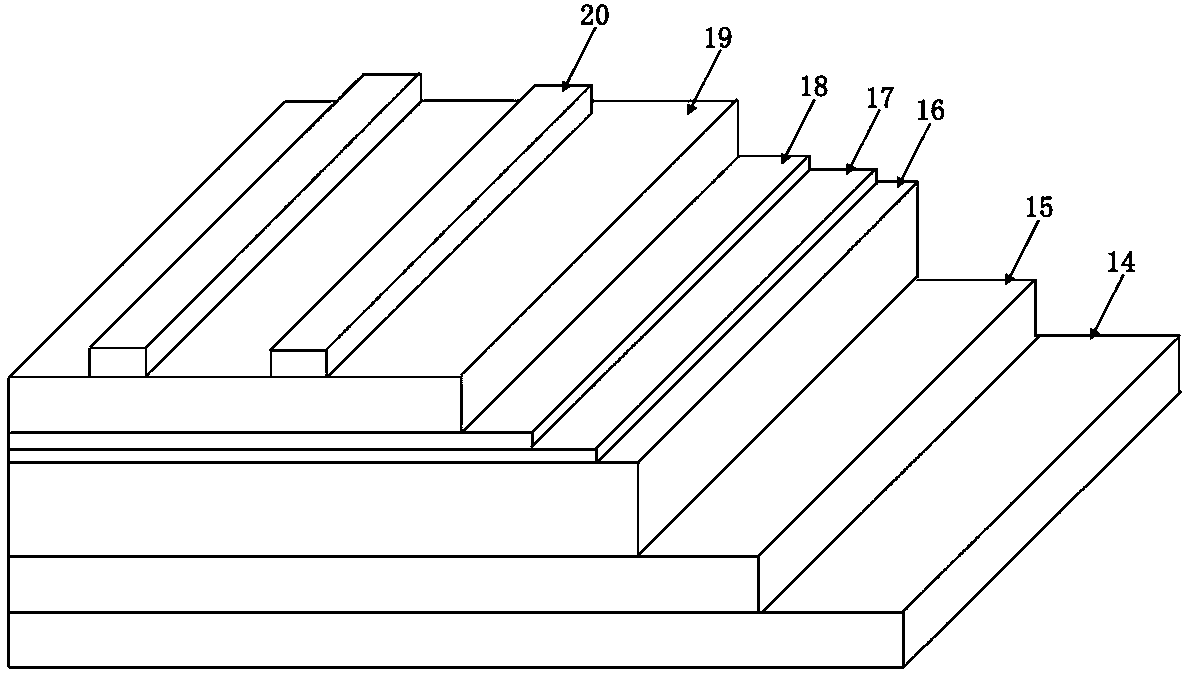

[0026] Example 2 Application of the method of the present invention to prepare antimony selenide thin film solar cells

[0027] The steps of preparing antimony selenide thin film solar cells with online selenium compensation are as follows:

[0028] (1) Substrate preparation

[0029] Using glass as a substrate, first soak the glass in an electronic cleaner solution for 12 hours, then take it out, rinse it with a large amount of deionized water, and blow it dry with nitrogen.

[0030] (2) Deposit molybdenum back electrode layer

[0031] The molybdenum (Mo) back electrode layer was prepared by magnetron sputtering technology: Ar gas was used as the reaction gas, the sputtering pressure was 0.4Pa, and the sputtering power density was about 4W / cm 2 , the thickness of the prepared molybdenum back electrode film is about 700nm, and its resistivity is about 3×10 -5 Ω·cm.

[0032] (3) Deposition of p-type antimony selenide semiconductor layer

[0033] Select the radio frequency m...

Embodiment 3

[0047] Select a glass substrate deposited with a Mo film with a thickness of 700nm as the substrate, and prepare an antimony selenide film with online selenium compensation:

[0048] (1) Using radio frequency magnetron sputtering process (sputtering power density is 1.5W / cm 2 , sputtering pressure 0.5Pa), using a circular antimony selenide target with a diameter of 10 cm in line with the stoichiometric ratio as the sputtering target, using Ar gas as the sputtering gas to sputter and deposit the antimony selenide layer on the substrate;

[0049] The deposition time of this step is set as 14min, and the thickness of the obtained antimony selenide layer is about 700nm,

[0050] (2) While sputtering and depositing the antimony selenide layer in step (1), a thermal evaporation process is used to perform selenium compensation online with high-purity (purity 99.99%) selenium particles as the evaporated selenium source.

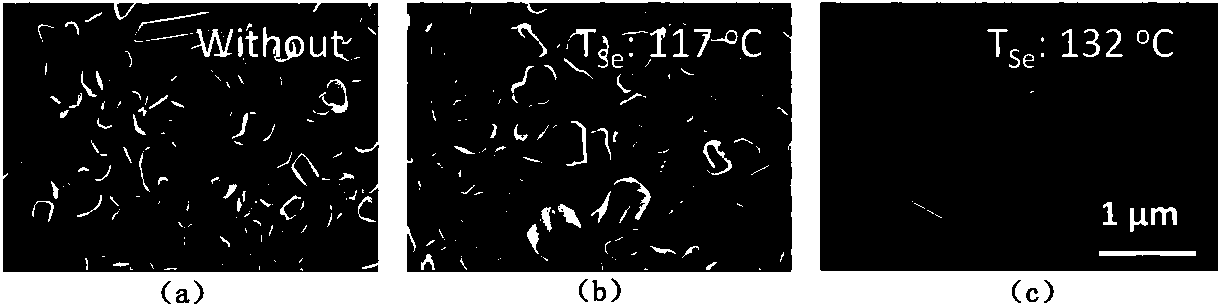

[0051] In this example, 2 groups of parallel experiments and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com