PVDF composite graphene filter element membrane and production process thereof

A composite graphene, production process technology, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of easy agglomeration, poor nanoparticle dispersion, PVDF membrane porosity and permeability decline, etc., to promote sterilization. effect, enhanced hydrophilicity, effect of saving manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

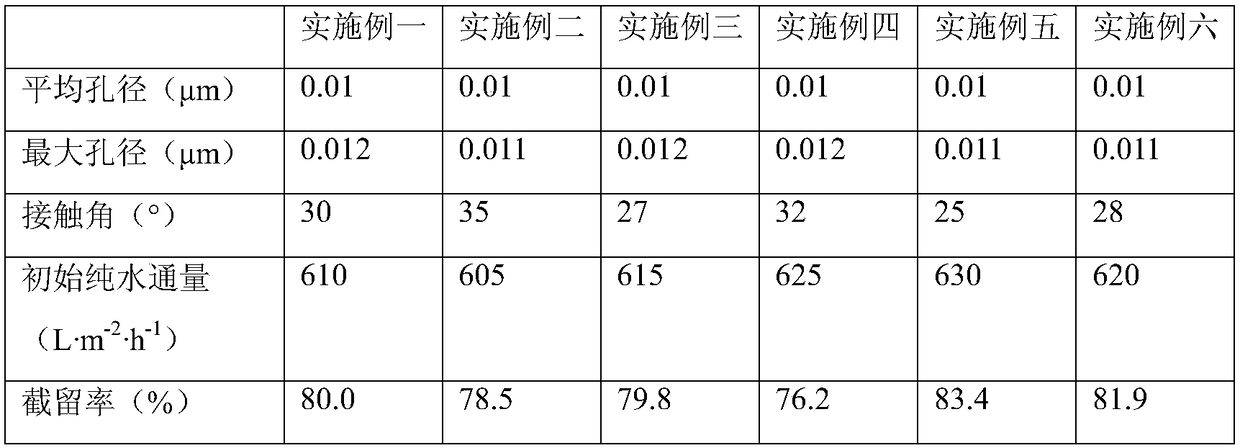

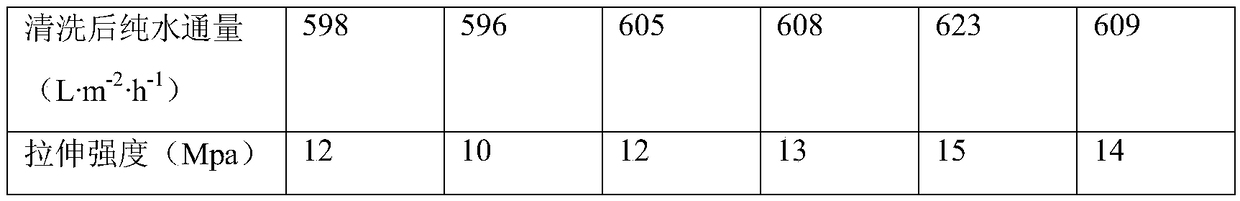

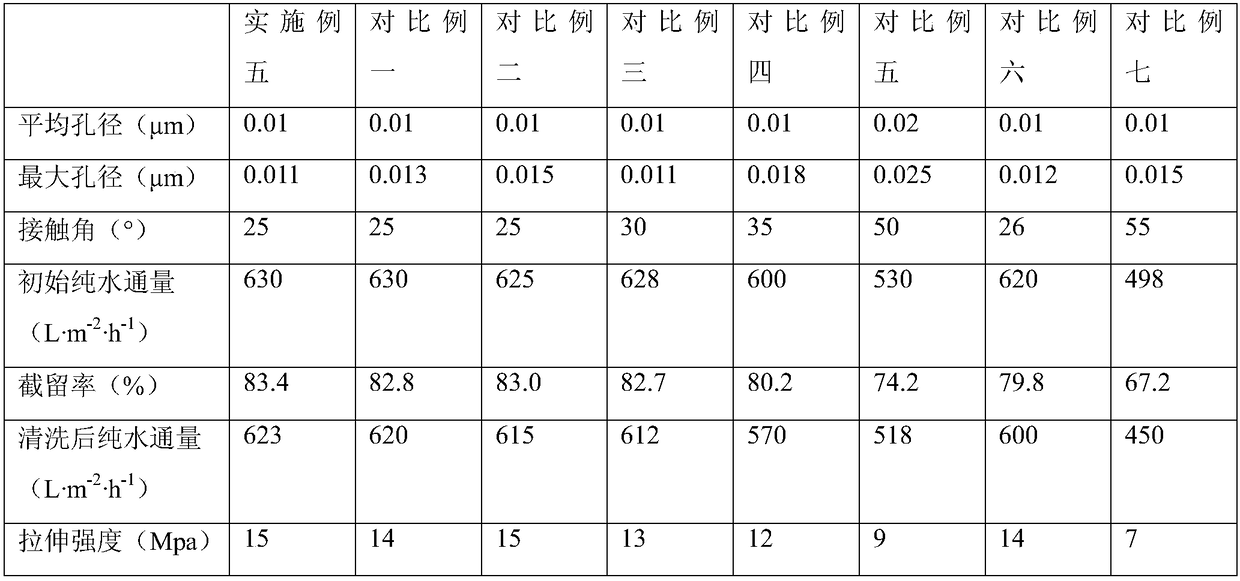

Examples

preparation example Construction

[0036] Preparation of modified graphene:

[0037] 1: Graphene oxide grafted PVP:

[0038] (1) Measure 200mL H 2 O is added graphene oxide 0.1g, after ultrasonic dispersion, obtain the graphene oxide dispersion liquid that concentration is 0.5mg / mL;

[0039] (2) Take by weighing 0.2g PVP and add in the graphene oxide dispersion liquid in step (1), fully stir until completely dissolving;

[0040] (3) Weigh 0.2 g of ascorbic acid and add it to step (2), and stir until it is completely dissolved to obtain a mixed system;

[0041] (4) heating the mixed system of step (3) in a 75°C oil bath for 4h to obtain a graphene oxide grafted PVP solution;

[0042] 2: Loading nano-silver particles:

[0043] (5) transfer the graphene oxide grafted PVP solution in the flask, fill with nitrogen for 10min, and remove the air in the flask;

[0044] (6) Add 0.01g nano silver nitrate powder to step (5), stir for 20min;

[0045] (7) Add the newly prepared 0.128mol / L NaBH dropwise under heating in ...

Embodiment 1

[0051] Step1. Put the PVDF homopolymer into a drying oven at 90°C and dry for 3 hours;

[0052] Step2. Put 45 parts of PVDF homopolymer, 75 parts of DMAC, 1.8 parts of PVP-K30, 0.2 parts of PVP-K90, and 2.5 parts of modified graphene into the reactor, set the temperature at 95°C, and prepare the spinning solution;

[0053] Step3. After the spinning solution is left to defoam, it is spun and formed to make a tow;

[0054] Step4. After soaking the tow in 10% ethanol solution for 10 minutes by mass fraction, put it into the coagulation tank and soak for 28 hours to obtain a hollow fiber bundle with stable pore size;

[0055] Step5. After the hollow fiber bundle is dried, the filter element membrane is obtained.

Embodiment 2

[0057] Step1. Put the PVDF homopolymer into a drying oven at 80°C and dry for 3 hours;

[0058] Step2. Put 30 parts of PVDF homopolymer, 60 parts of DMAC, 0.9 parts of PVP-K30, 0.1 part of PVP-K90, and 0.5 parts of modified graphene into the reaction kettle, set the temperature at 85°C, and prepare the spinning solution;

[0059] Step3. After the spinning solution is left to defoam, it is spun and formed to make a tow;

[0060] Step4. Soak the tow in a 10% ethanol solution by mass fraction for 10 minutes, then put it into the coagulation pool and soak for 24 hours to obtain a hollow fiber bundle with stable pore size;

[0061] Step5. After the hollow fiber bundle is dried, the filter element membrane is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com