Production method of constant-temperature oil preparation by using camellia oleifera seeds and refining purification

A production method and camellia seed technology, which are applied in the directions of fat oil/fat production, fat oil/fat refining, and fat production, etc., can solve the problems of unscientifically mature and targeted processes, high failure rate of production equipment, and low degree of mechanical automation. , to achieve the effect of low power for equipment configuration selection, easy automatic control, and avoidance of color deepening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

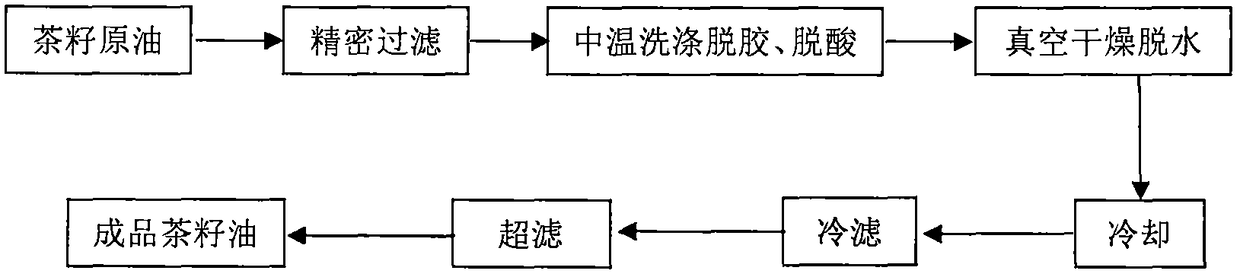

[0034] The invention provides a production method for constant temperature oil production and refining and purification of Camellia oleifera seeds, which includes the following production methods:

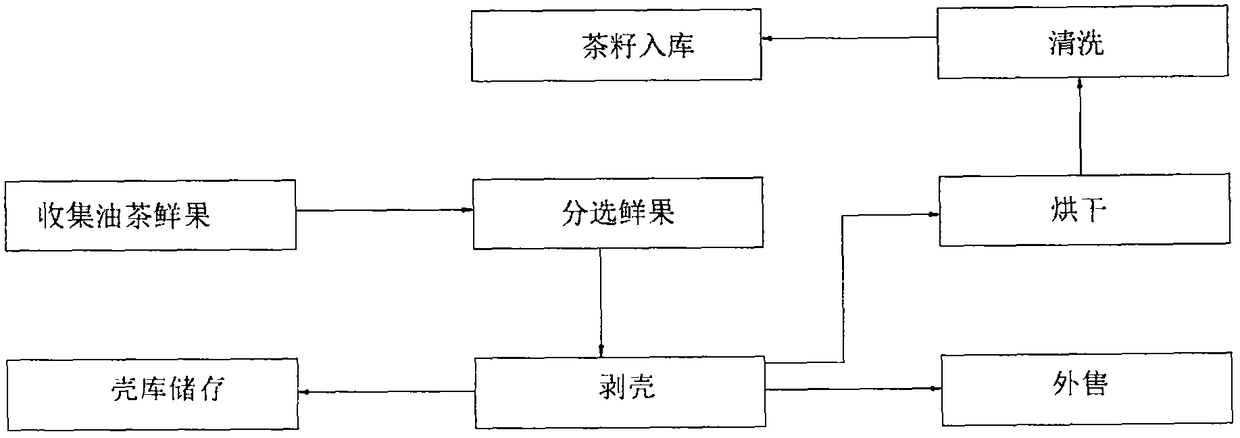

[0035] Step 1: Select the fresh Camellia oleifera fruit with full grains, and make a backup for use in subsequent processes;

[0036] Step 2: Sorting the fresh camellia oleifera fruits backed up in step 1, removing low-quality fresh camellia oleifera fruits, classifying the fresh camellia oleifera fruits according to the size of the fresh camellia oleifera fruits on the sorting sieve, and placing the fresh camellia oleifera fruits of similar size together for processing;

[0037] Step 3: Shelling the fresh camellia oleifera fruit sorted in step 2 by the green fruit shelling machine to separate the seed shells, store the fresh camellia oleifera fruit shells in the shell warehouse, and sell the fresh camellia oleifera fruit shells to outsiders;

[0038] Step 4: Place the fresh camell...

Embodiment 2

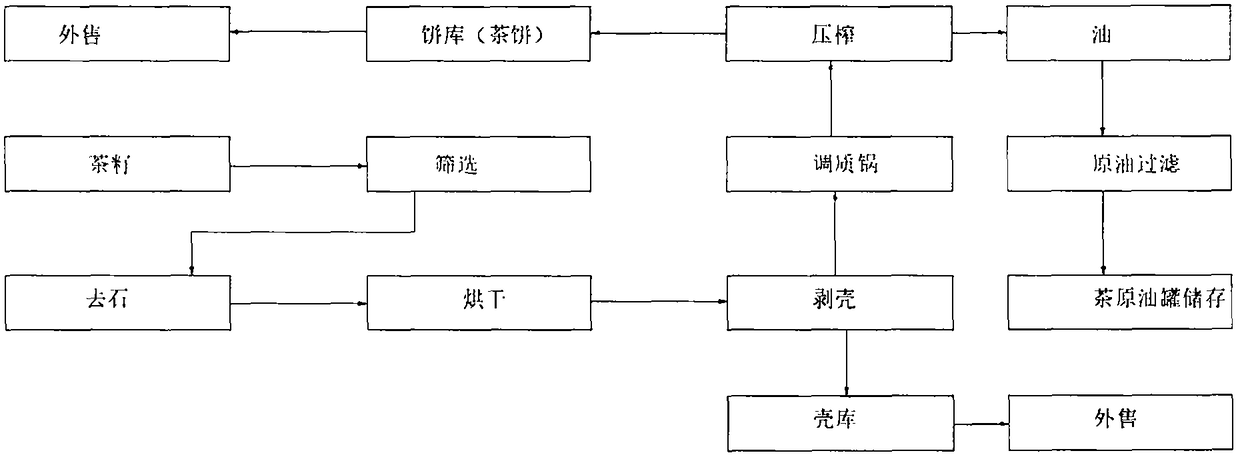

[0048] The invention provides a production method for constant temperature oil production and refining and purification of Camellia oleifera seeds, which includes the following production methods:

[0049] Step 1: Select the fresh Camellia oleifera fruit with full grains, and make a backup for use in subsequent processes;

[0050] Step 2: Sorting the fresh camellia oleifera fruit backed up in step 1, and cleaning the fresh camellia oleifera fruit with a vibrating sieve;

[0051] Step 3: Shelling the fresh camellia oleifera fruits sorted in step 2 by the green fruit shelling machine to separate the seed shells;

[0052] Step 4: Place the fresh camellia oleifera seeds separated from the seed shells in step 3 in a drying tower for constant air drying at a constant air temperature of 25°;

[0053] Step 5: Put the tea seeds that have been cleaned by wind in step 4 into the cleaning sieve for screening, and use the cleaning sieve to screen the sundries in the tea seeds, and then pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com