Electrolyte for alkali aluminum air cell battery and matched electrolyte box thereof

An electrolyte tank and electrolyte technology, which is applied in the direction of fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve the problem of accumulation of aluminum hydroxide particles, easy accumulation of aluminum hydroxide particles, accelerated and other problems, to achieve good fluidity, low cost, and increase the effect of settling velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

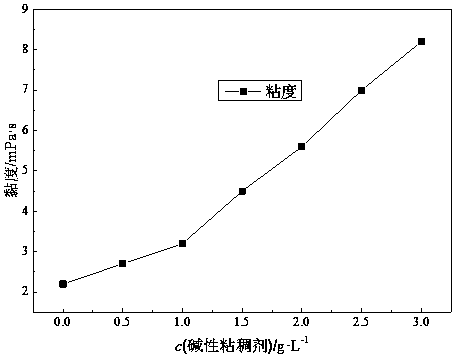

[0021] Specific embodiment 1: What this embodiment records is an electrolyte solution for an alkaline aluminum-air battery pack, the electrolyte solution is composed of potassium hydroxide or sodium hydroxide 2~8 mol / L, sodium stannate 0.01~0.15 mol / L, alkaline flocculant 0.5~10 g / L, and the balance is composed of water. The specific preparation method is as follows: adding potassium hydroxide or sodium hydroxide and sodium stannate into distilled water in sequence, stirring thoroughly, adding alkaline flocculant and stirring evenly again.

specific Embodiment approach 2

[0022] Specific embodiment two: a kind of electrolytic solution for alkaline aluminum-air batteries described in specific embodiment one, the described alkaline flocculant is one of anionic polyacrylamide, sodium polyacrylate or polyaluminum chloride or A mixture of several.

specific Embodiment approach 3

[0023] Specific embodiment three: a kind of electrolyte solution for alkaline aluminum-air batteries described in specific embodiment two, the molecular weight of the described anionic polyacrylamide is 200-20 million, and the molecular weight of the described sodium polyacrylate is 400-30 million .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com