Flexible pressure sensor chip based on 3D printing technology and production method thereof

A pressure sensor, 3D printing technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of difficult to process true three-dimensional free-form structures, low processing efficiency, complex processing technology, etc., to expand material selection Scope, short cycle time, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

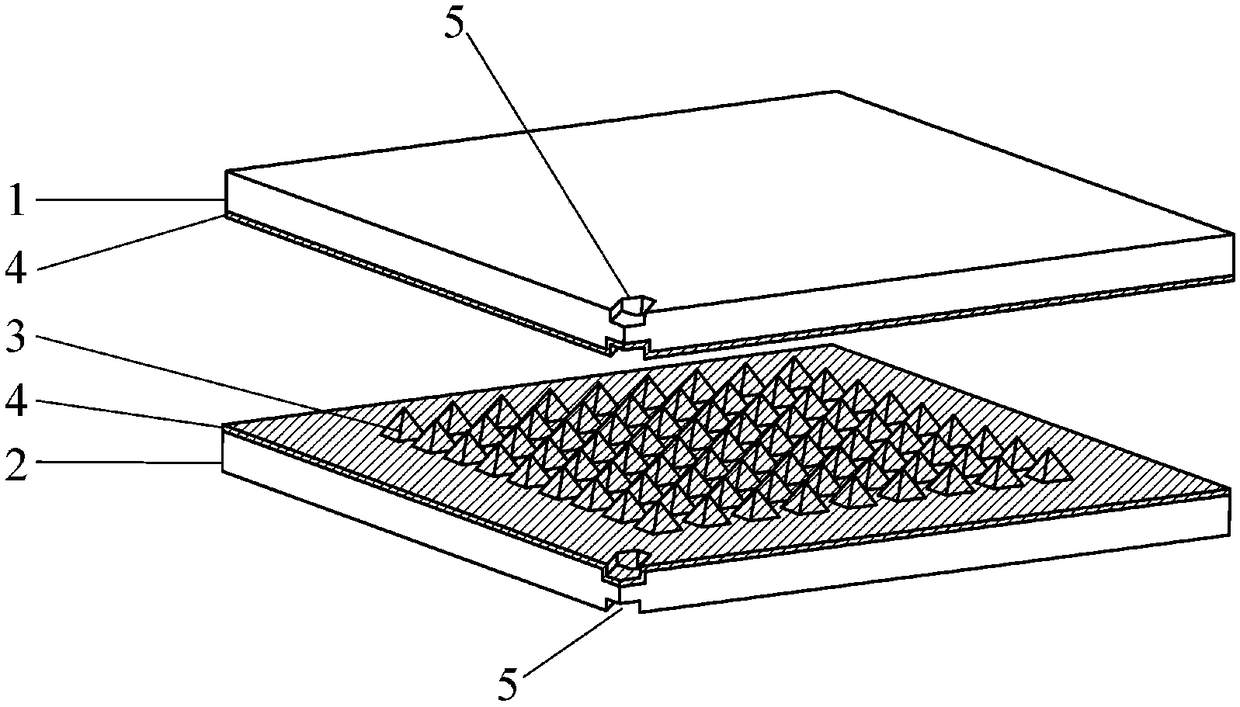

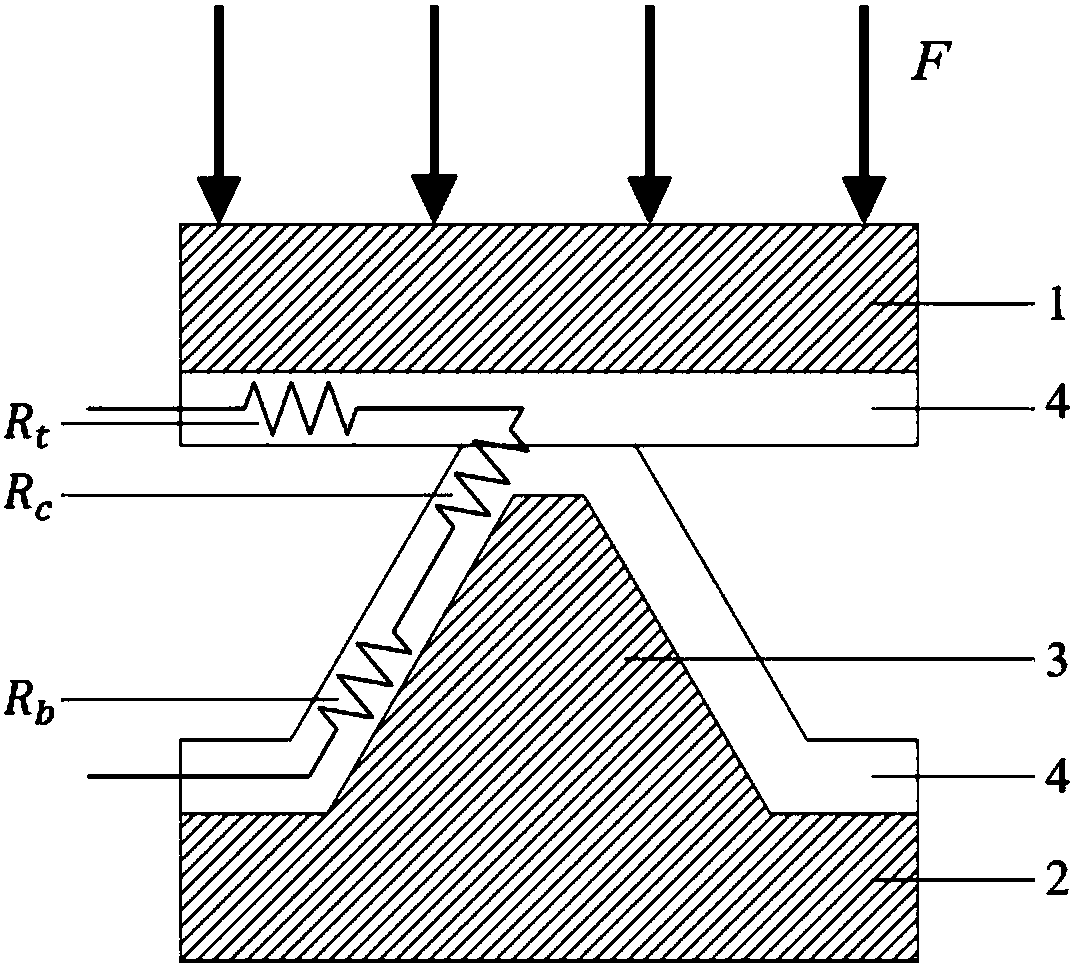

[0022] Such as figure 1 and figure 2 As shown, a flexible pressure sensor chip based on 3D printing technology includes a flexible upper plate 1, a flexible upper plate 1 and a flexible lower plate 2 evenly distributed micro-pyramid array 3 are in contact, and the flexible upper plate 1 and The flexible lower pole plate 2 contacts the surface to make a flexible thin film electrode 4, the flexible thin film electrode 4 on the flexible upper pole plate 1 and the flexible thin film electrode 4 on the flexible lower pole plate 2 are connected to the external circuit through a wire, and the wire is located on the flexible upper pole plate 1 In the through hole 5 provided on the corner corresponding to the flexible lower pole plate 2 .

[0023] The flexible upper plate 1 and the flexible lower plate 2 are made of photosensitive flexible polyurethane resin material.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com