Multifunctional concrete curing agent, as well as preparation method and application thereof

A concrete curing agent, multi-functional technology, applied in the field of construction engineering, can solve problems such as peeling off, affecting concrete construction, affecting concrete performance, etc., to improve durability and crack resistance, and improve chemical medium erosion and durability , the effect of super penetration and crystallization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

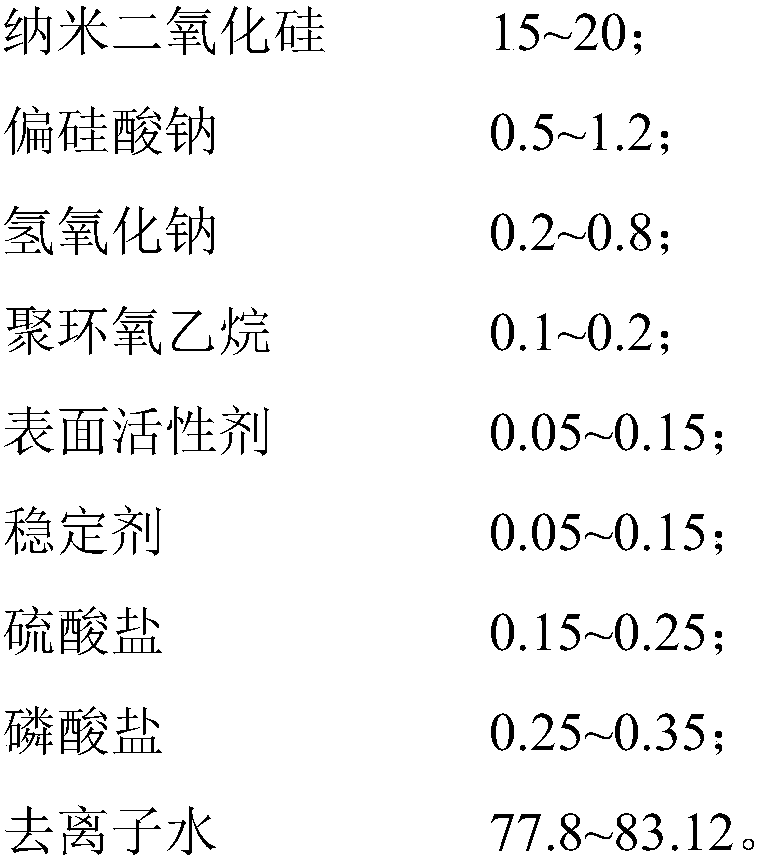

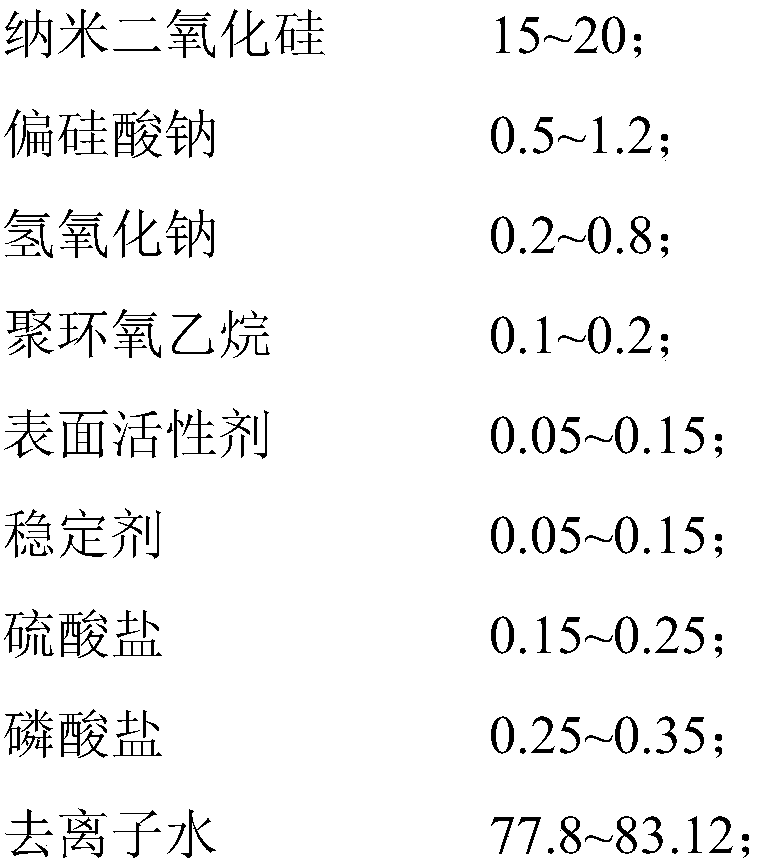

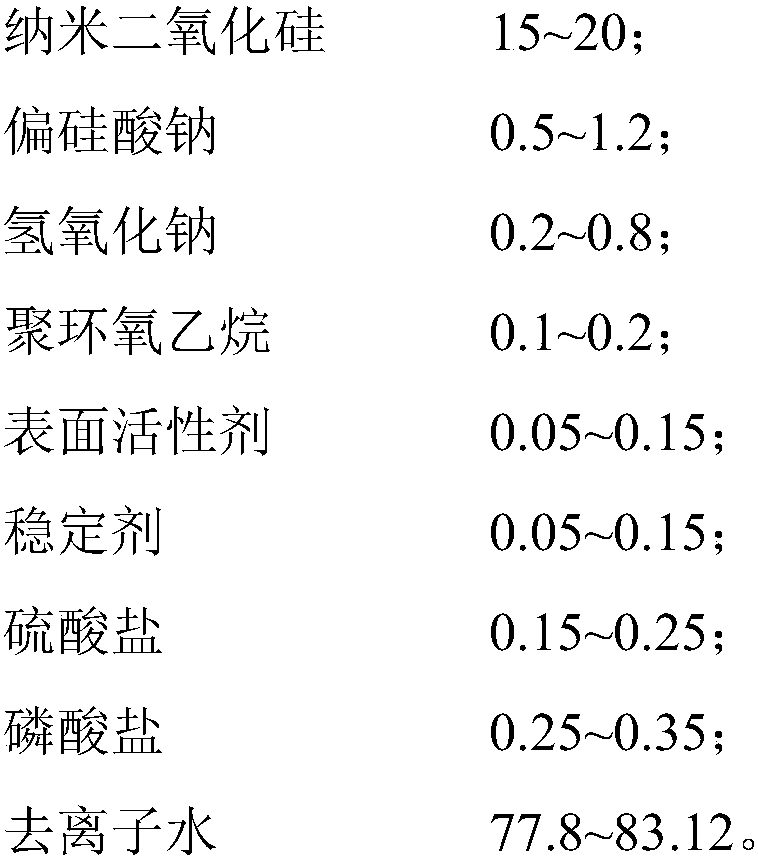

[0031] The composition and percentage by weight of the present embodiment are 20% of nano silicon dioxide; 1% of sodium metasilicate; 0.5% of sodium hydroxide; 0.1% of polyethylene oxide; 0.05% of surfactant; 0.1% of stabilizer; 0.15%; sodium polyphosphate 0.3%; deionized water 77.8%. To prepare a 100kg sample for trial mixing.

[0032] The first step is to weigh 77.8kg of deionized water and place it in the reactor, heat it to 90-100°C, slowly add 20kg of nano-silica and keep stirring. Add 1kg of sodium metasilicate and 0.5kg of sodium hydroxide to the reactor, and close the feeding port to maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 100°C, the stirrer stirs at a high speed for 10 minutes, and the stirring speed is 250 rpm.

[0033] The second step is to open the feeding port, put in 0.15kg of sodium sulfate and 0.3kg of sodium polyphosphate in turn, close the feeding port, and maintain the working pressure of the reactor at 21g / cm ...

Embodiment 2

[0037] The composition and percentage by weight of the present embodiment are nano silicon dioxide 15%; Sodium metasilicate 0.8%; Sodium hydroxide 0.2%; Polyethylene oxide 0.15%; Surfactant 0.08%; Stabilizer 0.05%; 0.25%; sodium polyphosphate 0.35%; deionized water 83.12%. To prepare a 100kg sample for trial mixing.

[0038] The first step is to weigh 83.12kg of deionized water and place it in the reactor, heat it to 90-100°C, slowly add 15kg of nano-silica and keep stirring. Add 0.8kg of sodium metasilicate and 0.2kg of sodium hydroxide into the reactor, and close the feeding port to maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 100°C, the stirrer stirs at a high speed for 10 minutes, and the stirring speed is 350 rpm.

[0039] The second step is to open the feeding port, put in 0.25 kg of sodium sulfate and 0.35 kg of sodium polyphosphate in turn, close the feeding port, and maintain the working pressure of the reactor at 21g / cm 2 , w...

Embodiment 3

[0043] The composition and percentage by weight of the present embodiment are nano silicon dioxide 18%; Sodium metasilicate 0.5%; Sodium hydroxide 0.8%; Polyethylene oxide 0.2%; Surfactant 0.15%; Stabilizer 0.15%; 0.20%; sodium polyphosphate 0.25%; deionized water 79.9%. To prepare a 100kg sample for trial mixing.

[0044] The first step is to weigh 79.9kg of deionized water and place it in the reactor, heat it to 90-100°C, slowly add 18kg of nano-silica and keep stirring. Add 0.5kg of sodium metasilicate and 0.8kg of sodium hydroxide into the reactor, and close the feeding port to maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 100°C, the stirrer stirs at a high speed for 10 minutes, and the stirring speed is 550 rpm.

[0045] The second step, open the feeding port, put in 0.2kg of sodium sulfate and 0.25kg of sodium polyphosphate in turn, close the feeding port, and maintain the working pressure of the reactor at 21g / cm 2 , when the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com