Valve-controlled hydraulic transmission system applied to exoskeleton robot

An exoskeleton robot, hydraulic transmission technology, applied in the direction of fluid pressure actuation device, manipulator, mechanical equipment, etc., can solve the problems of large ineffective energy consumption, increase energy consumption, increase manufacturing cost, etc., achieve less potential failure points, work Fast, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

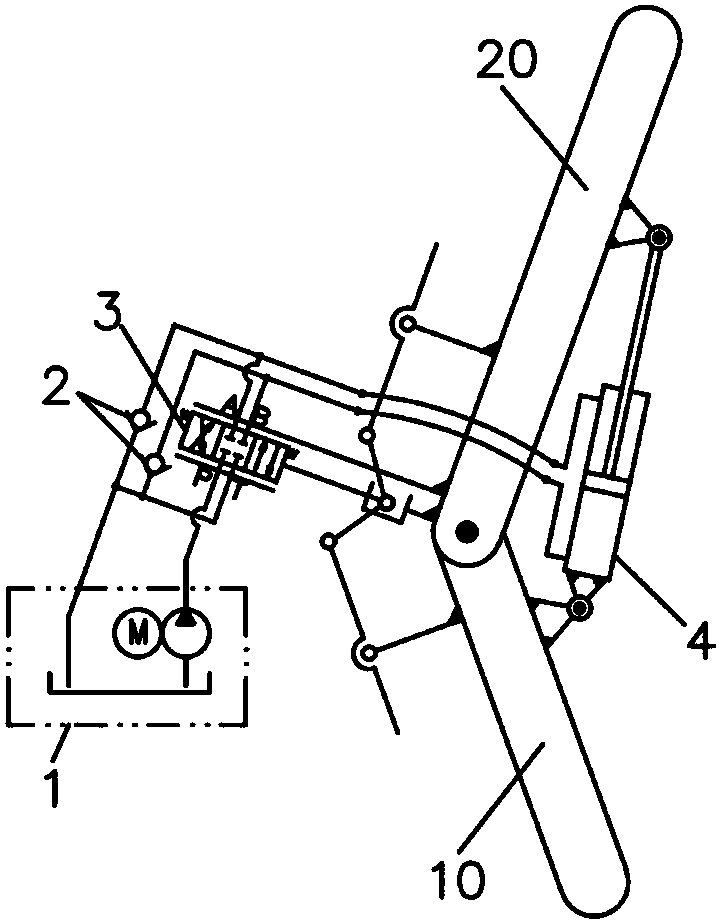

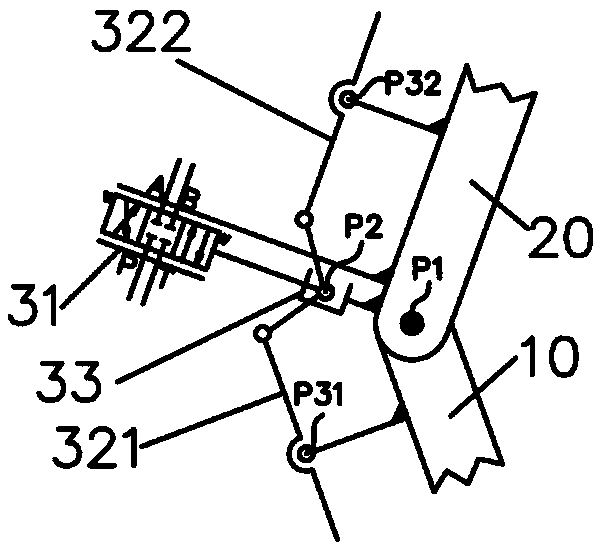

[0086] see figure 1, is a schematic diagram of an embodiment in which the present invention is applied to an exoskeleton robot to assist the knee joint. The first mechanical arm (mechanical lower leg A-1) and the second mechanical arm (mechanical thigh A-2) of the exoskeleton robot are hinged together through the P1 point (note: the first mechanical arm and the second mechanical arm are collectively referred to as mechanical arm; the actual design of the mechanical arm may adopt a more complex articulation method, but the present invention focuses on the hydraulic transmission and its control scheme, and the mechanical structure is only used to express the design intent). When the exoskeleton robot is worn on the human body, the human calf and human thigh are respectively close to the first mechanical arm (mechanical calf A-1) and the second mechanical arm (mechanical thigh A-2).

[0087] The present invention includes a hydraulic oil source 1, an oil replenishment check valv...

Embodiment 2

[0110] See attached Figure 4 It is a schematic diagram of an embodiment of the present invention that adopts a single-acting oil cylinder to assist the knee joint, and it is combined with the attached figure 1The only difference is that the single-acting oil cylinder 41 is used to assist, and the manual servo valve 3 can use a three-position three-way manual servo valve 31, which has at least one oil inlet, one oil return port, and one oil outlet. It acts on the oil inlet chamber of the oil cylinder 41 , and the oil outlet has a fuel supply check valve 2 connected to the oil tank 110 . Of course, the manual servo valve 3 can also be used as figure 1 The three-position four-way servo valve 32 is shown, with one outlet plugged and unused, making it equivalent to a three-position three-way manual servo valve, although this is not preferred.

[0111] A single-acting oil cylinder is used to assist, and its basic working principle is the same as that of a double-acting oil cylind...

Embodiment 3

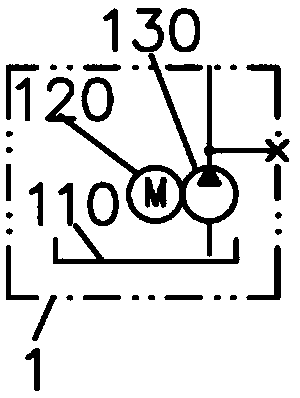

[0115] See attached Figure 5 It is a schematic diagram of the second embodiment of the hydraulic oil source of the present invention, which is attached to image 3 The only difference is that the outlet of the hydraulic pump 130 is connected to the high-pressure accumulator 140 through a check valve for maintaining pressure. For hydraulically driven exoskeleton robots that require high response speed, the hydraulic oil source used should be a constant pressure oil source, and a high-pressure accumulator is installed to help increase the instantaneous maximum oil supply flow. The high-pressure accumulator can also act as a buffer effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com