Preparation method of sugarcane seedling soaking agent

A technology of seed soaking agent and sugarcane, which is applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problems of not being able to meet production needs and unstable promotion effects, and achieve the benefits of pest control, stable germination rate, and promotion of The effect of bud growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

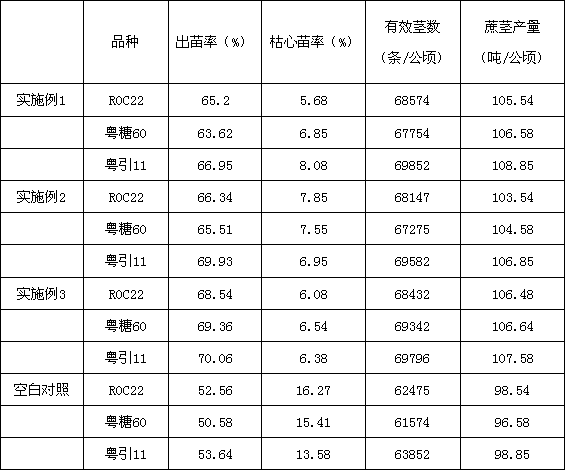

Examples

Embodiment 1

[0017] Described sugarcane seed soaking agent comprises the raw material of following mass parts ratio:

[0018] a) 20 parts of kelp powder;

[0019] b) 10 parts of potassium humate;

[0020] c) 5 parts of a mixture of oligosaccharin and thiabendazole, the ratio of oligosaccharin to thiabendazole is 2:3;

[0021] d) 5 parts of copper sulfate;

[0022] e) 5 parts of lime powder;

[0023] f) 1 part of active tricalcium phosphate;

[0024] g) 2 parts of benzylaminopurine;

[0025] h) 5 parts of mycin and gibberellin active protective agent; the ratio of mymycin to gibberellin active protective agent is 1:3.5;

[0026] Among them, the fresh kelp is crushed after dehumidification and drying, passed through a 40-mesh sieve, potassium humate, amino oligosaccharides, copper sulfate, lime, benzyl aminopurine, mycin and gibberellin active protective agent are mixed evenly, and the mixture is formed and passed through 100 The fine powder is obtained through a mesh sieve; the fine p...

Embodiment 2

[0029] Described sugarcane seed soaking agent comprises the raw material of following mass parts ratio:

[0030] a) 40 parts of kelp powder;

[0031] b) 15 parts of potassium humate;

[0032] c) 10 parts of a mixture of oligosaccharin and thiabendazole, the ratio of oligosaccharin to thiabendazole is 2:3;

[0033] d) 10 parts of copper sulfate;

[0034] e) 10 parts of lime powder;

[0035] f) 3 parts of active tricalcium phosphate;

[0036] g) 5 parts of benzylaminopurine;

[0037] h) 10 parts of mycin and gibberellin active protective agent; the ratio of mycin and gibberellin active protective agent is 1:3.5;

[0038] Among them, fresh kelp is crushed after dehumidification and drying, passed through a 60-mesh sieve, potassium humate, amino oligosaccharides, copper sulfate, lime, benzylaminopurine, mycin and gibberellin active protective agent are mixed evenly, and the mixture is formed and passed through 200 The fine powder is obtained through a mesh sieve; the fine po...

Embodiment 3

[0041] Described sugarcane seed soaking agent comprises the raw material of following mass parts ratio:

[0042] a) 30 parts of kelp powder or seaweed powder;

[0043] b) 12 parts of potassium humate;

[0044] c) 8 parts of a mixture of oligosaccharin and thiabendazole, the ratio of oligosaccharin and thiabendazole is 2:3

[0045] d) 8 parts of copper sulfate;

[0046] e) 8 parts of lime powder;

[0047] f) 2 parts of active tricalcium phosphate;

[0048] g) 3.5 parts of benzylaminopurine;

[0049] h) 8 parts of mycin and gibberellin active protective agent, the ratio of mycin and gibberellin active protective agent is 1:3.5;

[0050] Among them, fresh kelp is crushed after dehumidification and drying, passed through a 50-mesh sieve, potassium humate, amino oligosaccharides, copper sulfate, lime, benzylaminopurine, mycin and gibberellin active protective agent are mixed evenly, and the mixture is formed and passed through 150 The fine powder is obtained through a mesh si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com