Device and method for removing VOCs (volatile organic chemicals) by high-voltage pulse dielectric barrier discharge combined with electrostatic micro-jet atomization

A dielectric barrier discharge, high-voltage pulse technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as inability to effectively remove VOCs, and achieve the effects of easy absorption, convenient cleaning, and reduced liquid usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

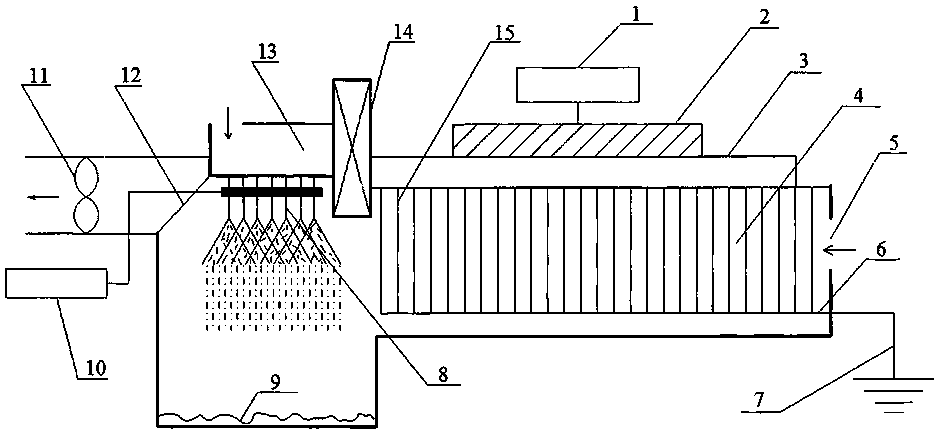

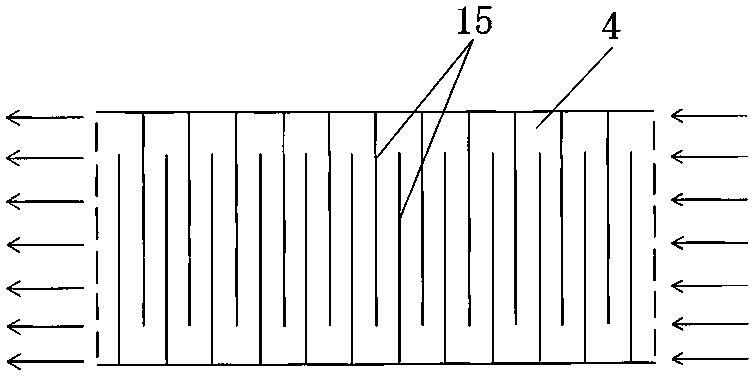

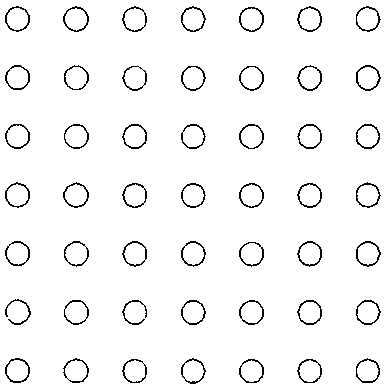

[0026] Embodiment 1: in combination with figure 1 , 2 , 3, a high-voltage pulse dielectric barrier discharge device combined with electrostatic micro-jet atomization to remove VOCs, including an air inlet 5, also includes a high-voltage discharge chamber 4, a high-voltage pulse dielectric barrier discharge device, an alkaline atomization area and The system power induced draft fan 11, the high-voltage pulse dielectric barrier discharge device forms a high-voltage discharge area in the discharge chamber 4, and the high-voltage pulse dielectric barrier discharge device includes a high-voltage pulse electrostatic generator 1, a high-voltage electrode plate 2, an insulating dielectric body 3, Wire mesh 6 and ground electrode 7, the high-voltage pulse electrostatic generator 1 is connected to the high-voltage electrode plate 2 through a wire with an insulating sheath, and the high-voltage electrode plate 2 is a flat plate electrode; the insulator 3 is arranged on the high-voltage e...

Embodiment 2

[0027] Embodiment 2: A method for removing VOCs using a high-voltage pulse dielectric barrier discharge combined with an electrostatic micro-jet atomization device for removing VOCs. The indoor air containing VOCs and bacteria is sucked into the high-pressure air through the air inlet 5 through the system power induced draft fan 11 In the discharge chamber 4, a high-voltage discharge area is formed in the discharge chamber 4 through a high-voltage pulse dielectric barrier discharge device, and high-energy electrons, free hydroxyl groups, ozone and active ions are formed to fully oxidize and decompose VOCs gas phase molecules, and kill bacteria in the air; The gas treated by the high-voltage pulse dielectric barrier discharge device enters the alkaline atomization area. The alkaline liquid used in the alkaline atomization area is an aqueous solution of sodium bicarbonate with a mass fraction of no more than 2%. The arrayed capillary atomizing nozzle 8 is in the Under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com