Preparation method of metal copper nanocluster not wrapped with surface ligand and application thereof

A technology of nanoclusters and surface ligands, which is applied in nanotechnology, metal processing equipment, nanotechnology, etc. for materials and surface science, and can solve problems such as the lack of preparation methods for copper nanoclusters without surface ligands, Achieve the effect of high purity, good dispersion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

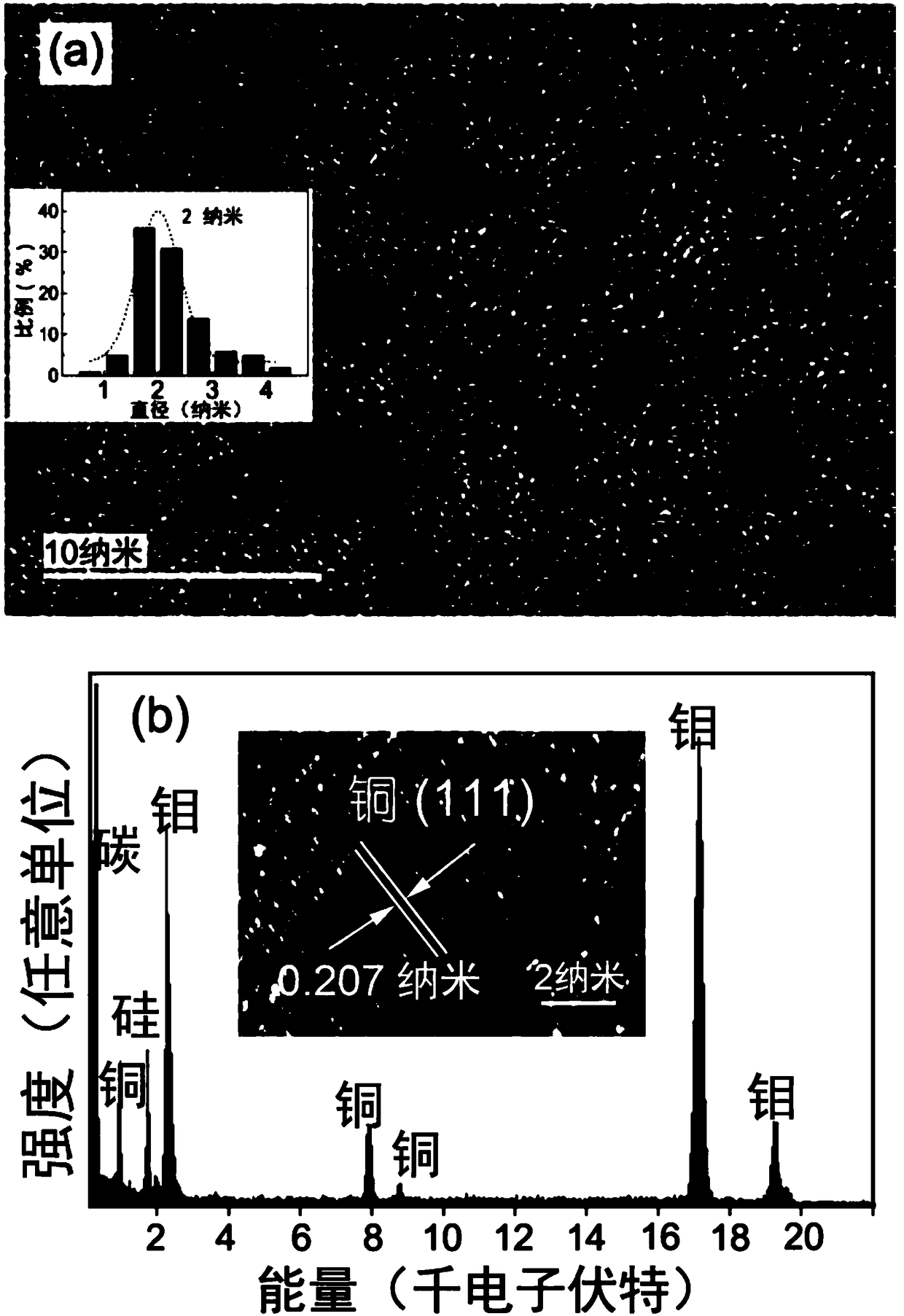

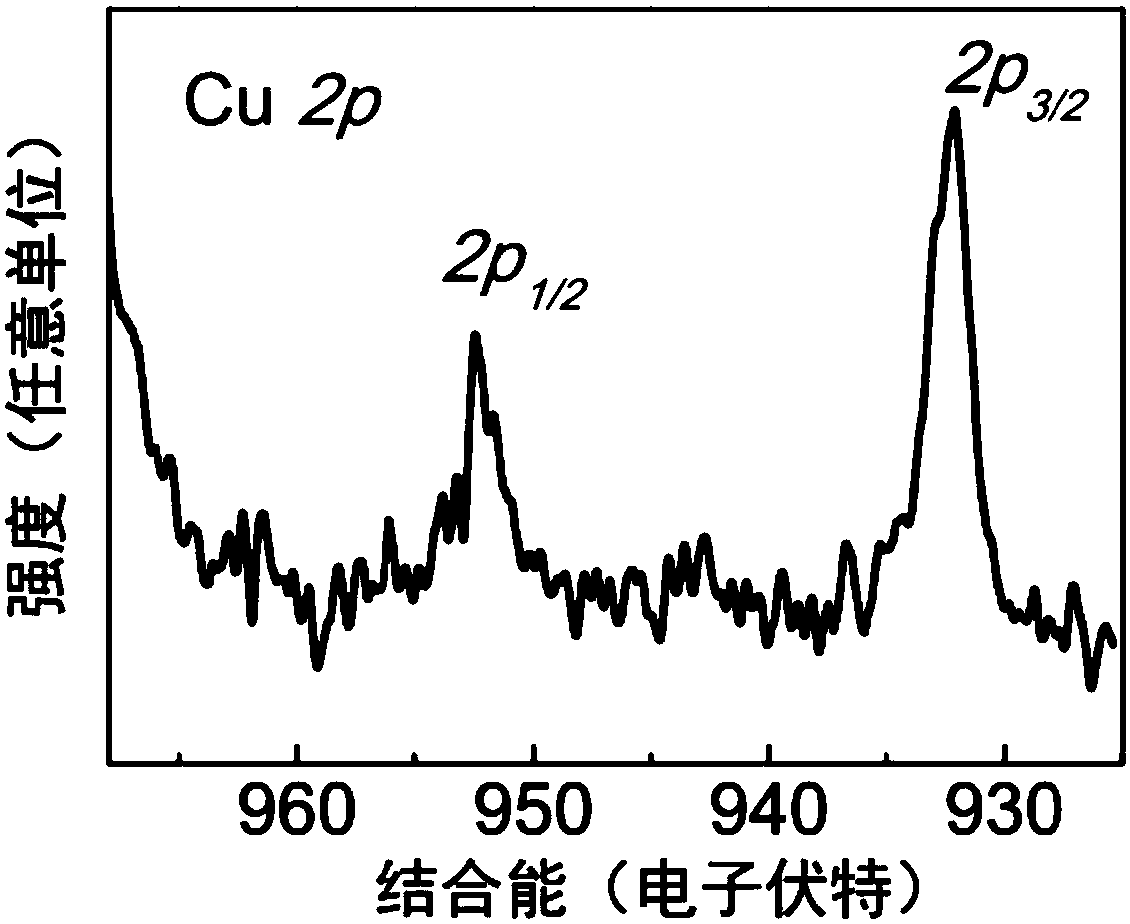

[0041] A method for preparing metal copper nanoclusters without surface ligand coating, comprising the following steps:

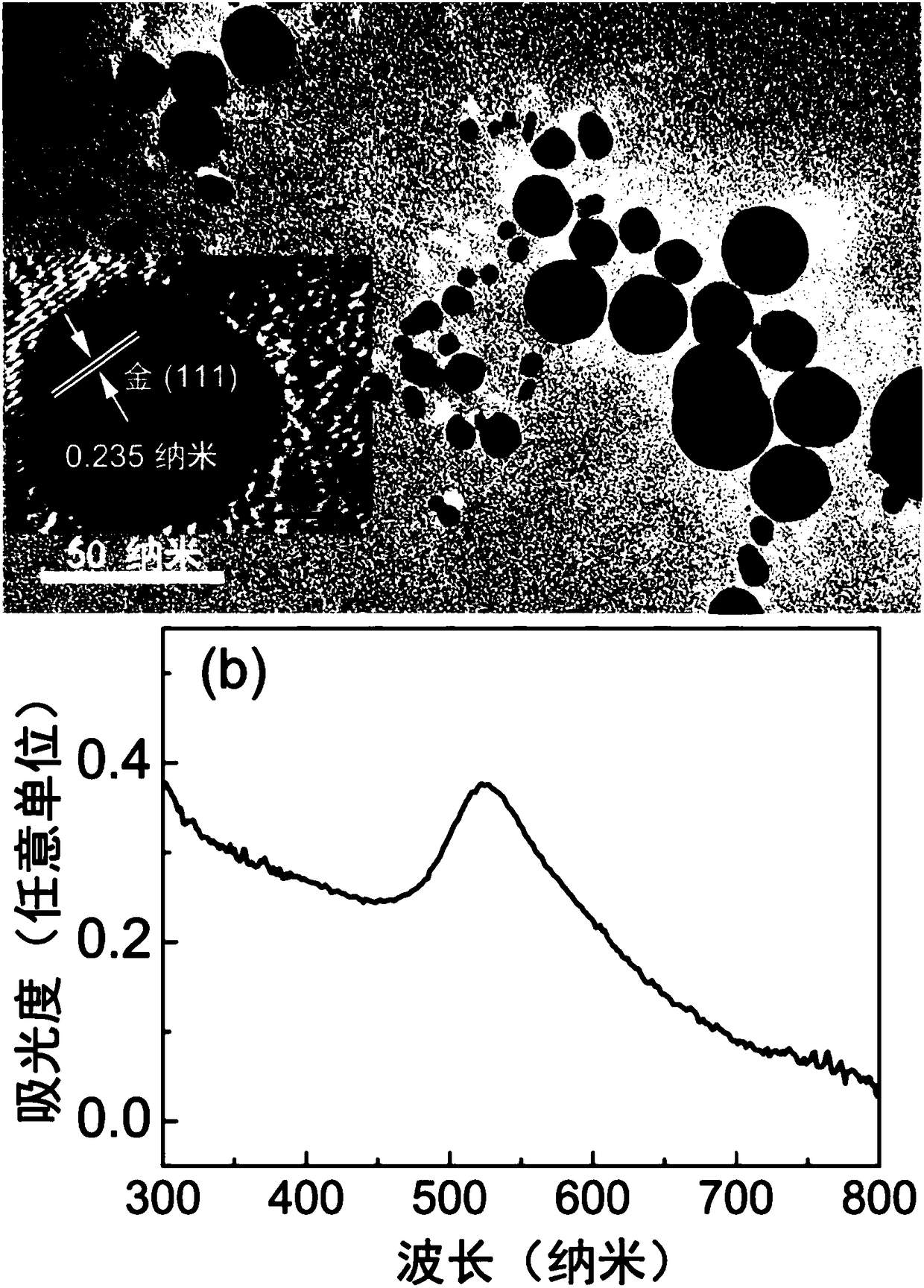

[0042] (1) Preparation of gold nanoparticles: put a gold plate with a size of 1 cm × 0.6 cm × 0.1 cm in 10 mL of deionized water, and then irradiate the gold plate with a laser with a wavelength of 1064 nm, with a spot diameter of 0.4 cm and an average laser power of 2 W / cm 2 , for a duration of 20 minutes to obtain a gold nanoparticle solution. Characterized by electron diffraction and transmission electron microscopy, the product is gold nanoparticles with a diameter of about 10-20 nanometers. After characterization such as absorption spectrum, it was confirmed that the position of the surface plasmon resonance absorption peak was 520 nanometers.

[0043] The content of gold nanoparticles in the solution was determined by the weight change of the gold plate before and after laser irradiation. In this embodiment, the mass loss of the gold plate was 0.2 mg...

Embodiment 2

[0055] A method for preparing metal copper nanoclusters without surface ligand coating, comprising the following steps:

[0056] (1) Preparation of gold nanoparticles: put a gold plate with a size of 1 cm × 0.6 cm × 0.1 cm in 10 mL of deionized water, and then irradiate the gold plate with a laser with a wavelength of 1064 nm, with a spot diameter of 0.4 cm and an average laser power of 2 W / cm 2 , for a duration of 20 minutes to obtain a gold nanoparticle solution. The product was characterized by electron diffraction and transmission electron microscopy as gold nanoparticles. The obtained gold nanoparticles are in a single crystal state with a diameter of about 10-20 nanometers; the mass loss of the gold plate is 0.2 mg, and the concentration of the colloidal gold nanoparticles solution is 0.02 mg / mL.

[0057] (2) Adjust the concentration of gold nanoparticle solution to 0.05 mg / mL, then take 1.5 mL of gold nanoparticle solution and place it in a quartz photocatalytic reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com