Method for modifying and preparing nano-silicon dioxide composite antioxidant in situ

A technology of nano-silica and composite antioxidants, which is applied in the field of in-situ modification to prepare nano-silica composite antioxidants, can solve complex and hard agglomerate process problems, achieve uniform particle size, advanced technology, Informative and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

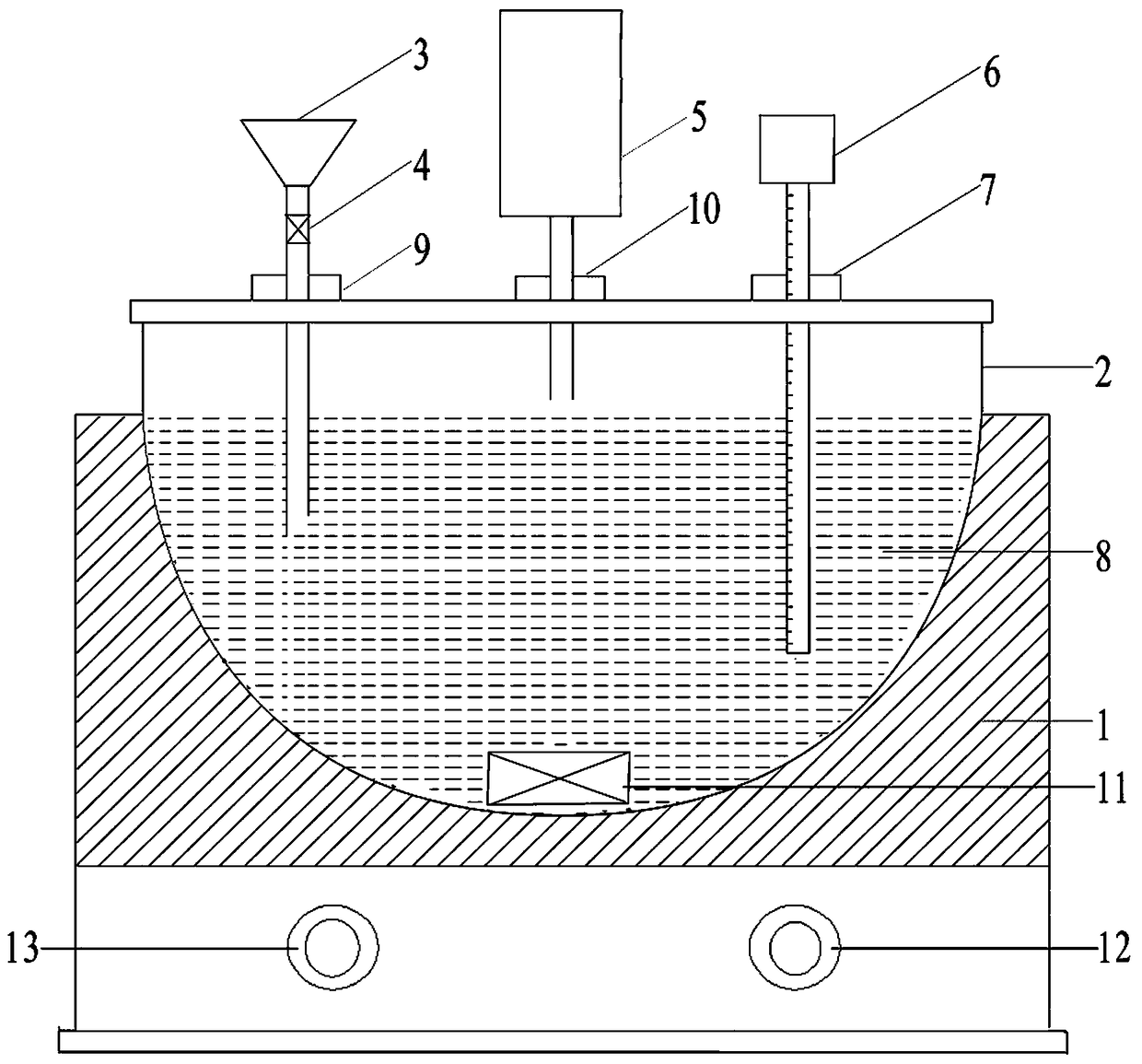

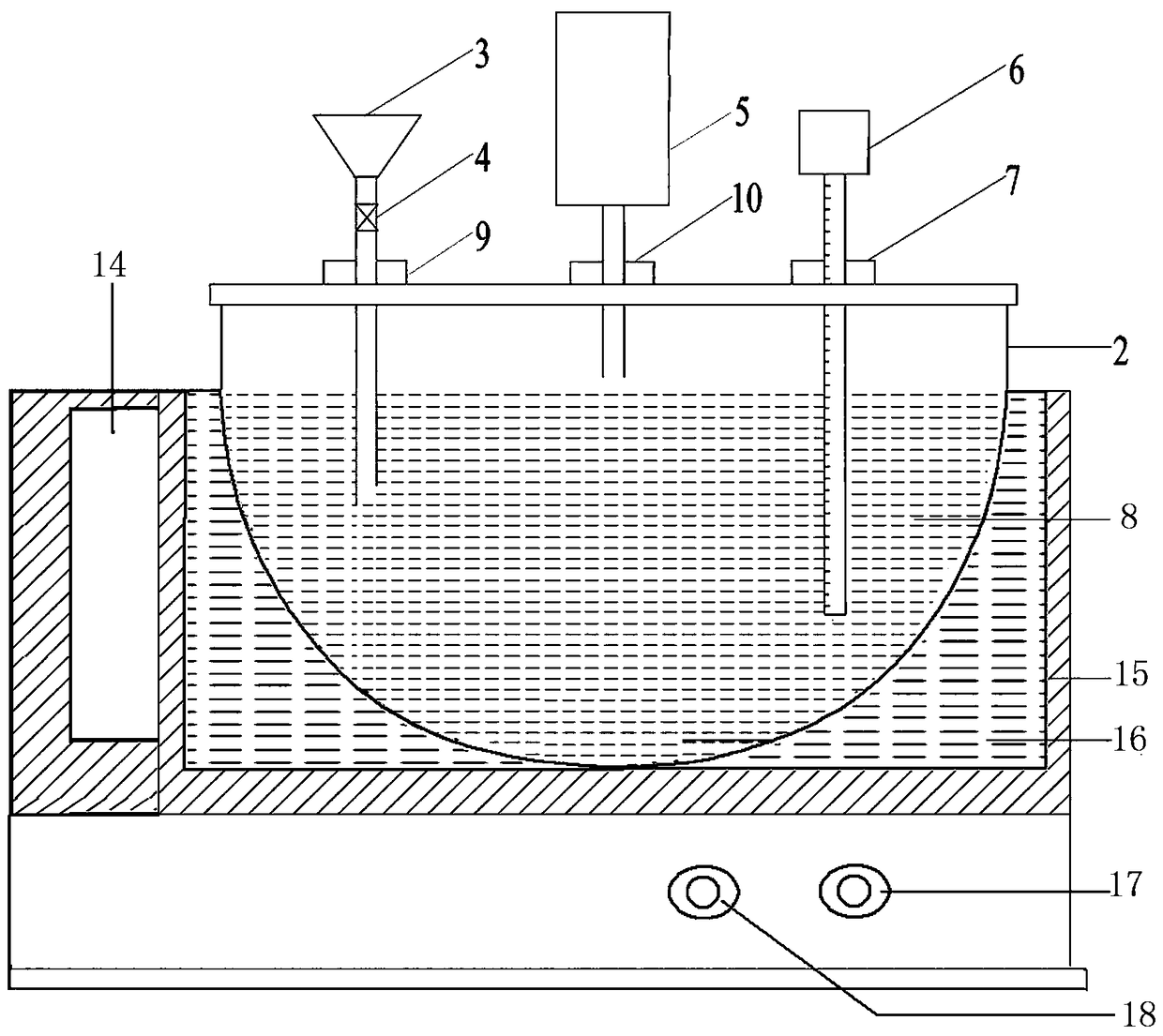

Method used

Image

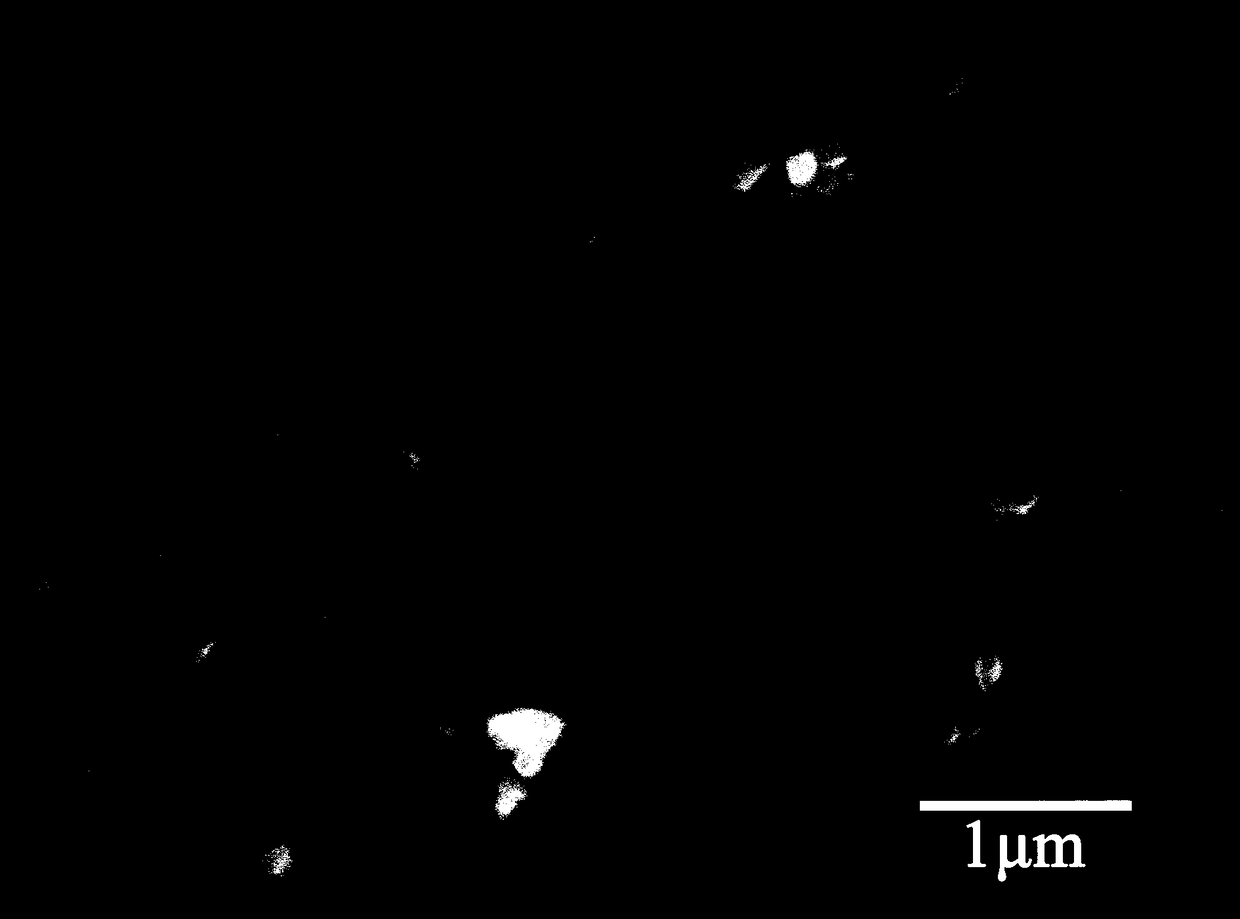

Examples

Embodiment 1

[0042] Example 1 A method for preparing nano-silica composite antioxidant by in-situ modification. The chemical materials used are: tetraethyl orthosilicate, ammonia water with a concentration of 25% in terms of mass fraction, absolute ethanol, and acetone , Antioxidant 1330, deionized water.

[0043] The preparation method is as follows:

[0044] (1) Selection of various chemical substances and materials

[0045] (2) Preparation of nano-silica composite antioxidant by in-situ modification

[0046] ① Prepare the solution

[0047] Measure 51ml of absolute ethanol and place it in a beaker for use; measure 29ml of ammonia water and place it in a conical flask with a rubber stopper for use; measure 5ml of tetraethyl orthosilicate and 50ml of absolute ethanol and place it in a beaker Mix, stir with a glass rod to make it evenly mixed and set aside; measure 45mg of antioxidant 1330 and dissolve it in 150ml of acetone, stir evenly to prepare an acetone solution, and place it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com