Hybridized perovskite microcrystal light-emitting material and preparation method and application thereof

A technology of microcrystalline materials and perovskite, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of cumbersome preparation methods, unfavorable cleaning and purification of quantum dots, etc., and achieve high luminous efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

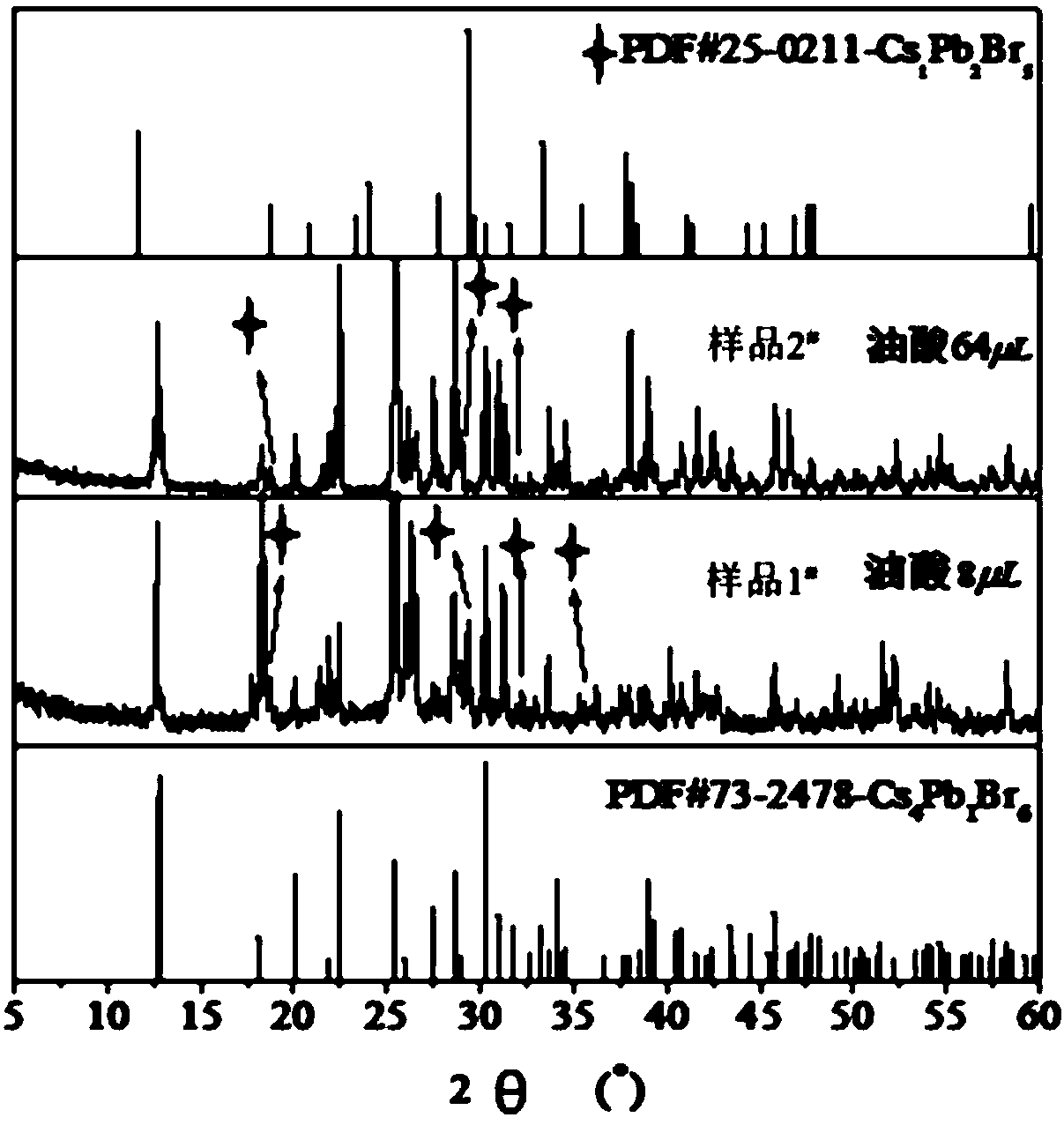

[0082] Embodiment 1 prepares perovskite material CsPb 2 Br 5 sample 1 #

[0083] (1) 1mol PbBr 2 , 4 mol CsBr and 8 μL oleic acid additive, dissolved in 1.1 mL of a fixed mixture of DMF and HBr (volume ratio 1:0.8) at room temperature.

[0084] (2) Use an external water bath to control the temperature of the mixture so that it is completely dissolved. The temperature of the water bath is controlled at 100°C and kept for 30 minutes after complete dissolution, then gradually lower the temperature to 10°C at a cooling rate of 10°C / h.

[0085] (3) After 3 days, the seed crystal grows slowly, and the shape is a cube (1×1×0.2mm 3 ). One month later, CsPb 2 Br 5 Nanocrystals successfully embedded in Cs 4 PbBr 6 The crystals, planted at the bottom of the flask, were illuminated with a UV lamp to reveal green sparkling crystals, which were then washed with butyrolactone and toluene and filtered.

[0086] The resulting sample is 1 # .

Embodiment 2

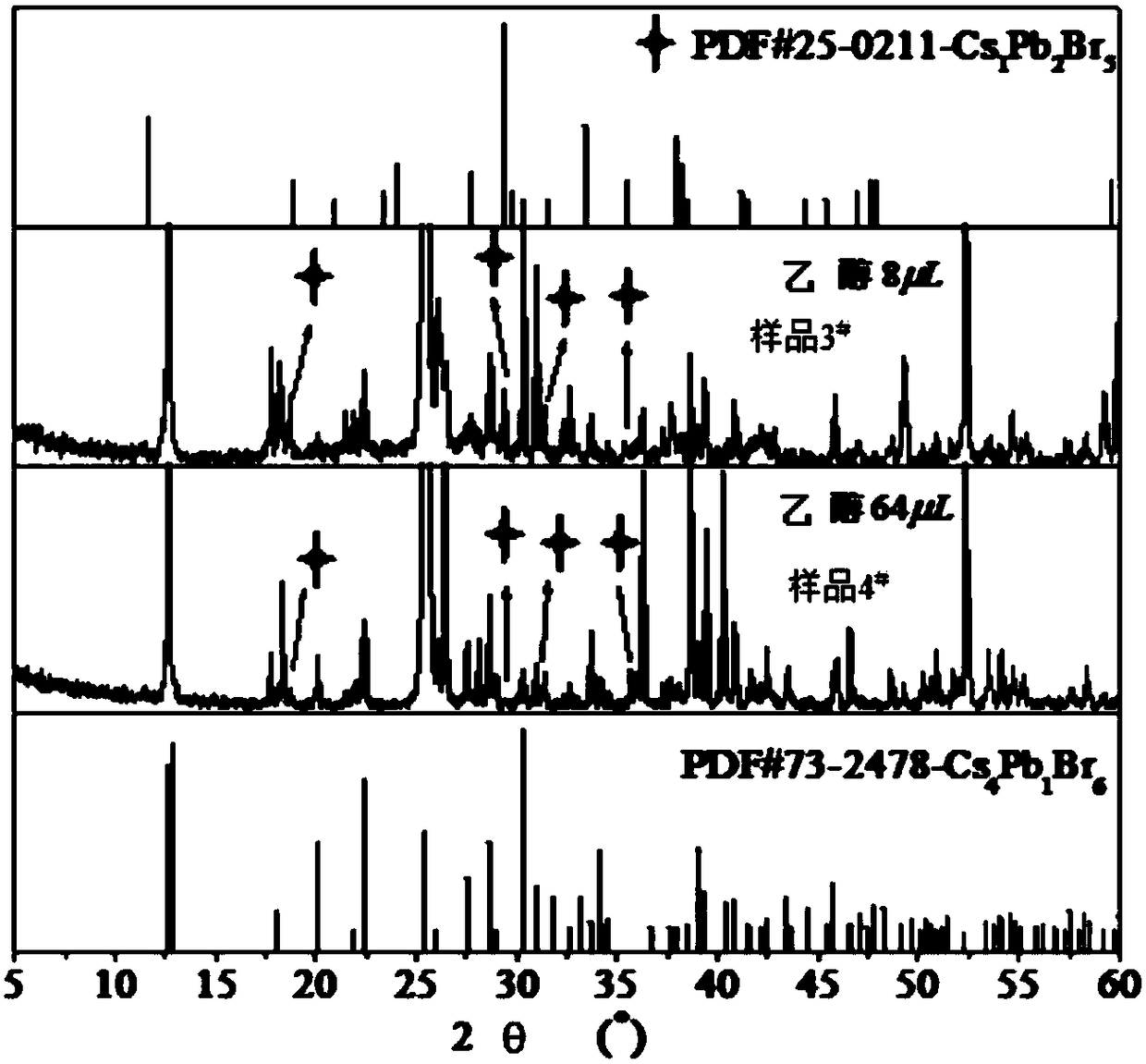

[0087] Embodiment 2 prepares perovskite material Cs 4 PbBr 6 sample 2 # ~4 #

[0088] The preparation process is the same as in Example 1, except that sample 2 # ~4 # Add 64 μL of oleic acid additive, 8 μL of ethanol additive, and 64 μL of ethanol additive, respectively.

Embodiment 3

[0089] Embodiment 3 prepares perovskite material sample 5 # ~10 #

[0090] The preparation process is the same as in Example 1, and the raw materials and reaction conditions are shown in the table below.

[0091] Table 1

[0092]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com