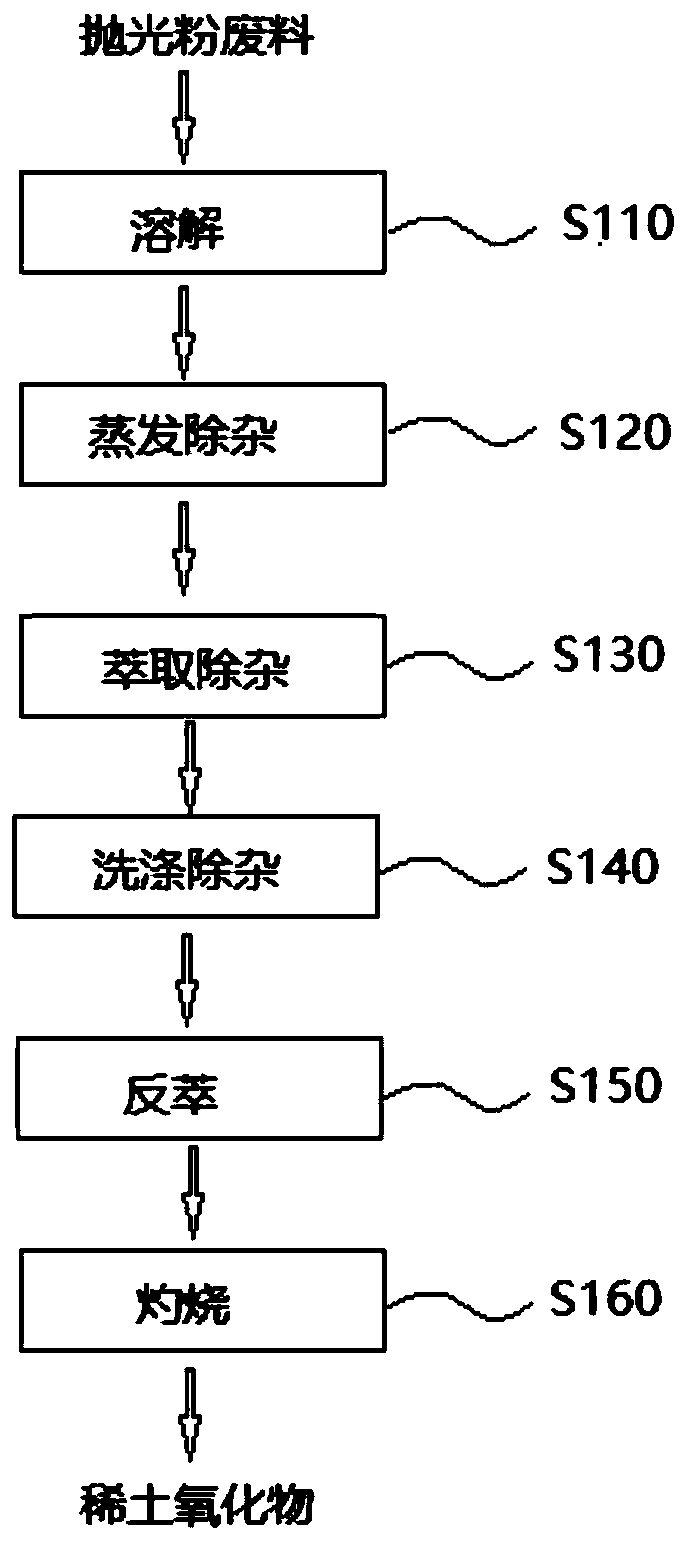

Method for Extracting Rare Earth Oxide from Polishing Powder Waste

A rare earth oxide and polishing powder technology, applied in the direction of improving the process efficiency, can solve the problems of low rare earth leaching yield, polluting the environment, difficult to meet the requirements of the polishing powder waste recycling process, etc., to meet the requirements of green environmental protection, improve The effect of rare earth recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1, dissolving: 100g polishing powder waste material (the REO of 64.4wt%, the Al of 2.44wt% 2 o 3 , 13.32wt% SiO 2 , 0.23% MgO, 5.53wt% F and 0.82wt% CaO) were added into 150 g of the first hydrochloric acid with a molar concentration of 10 mol / L, heated to 90° C. and stirred and dissolved for 2 hours to obtain a mother liquor containing rare earth elements.

[0070] 2. Evaporation and impurity removal: Evaporate and concentrate the above-mentioned rare earth element-containing mother liquor at 50° C. to nearly dryness, add 400 g of hot water after cooling, stir and dissolve, and press filter to obtain the impurity-removed rare earth element-containing mother liquor.

[0071] 3. Extraction and impurity removal: adjust the pH value of the above-mentioned rare earth element-containing mother liquor after impurity removal to 1 with 0.5mol / L fourth hydrochloric acid, add an organic extractant to extract twice (wherein the organic extractant and the rare earth element after ...

Embodiment 2

[0077] 1, dissolving: 100g polishing powder waste material (the REO that contains 64.4wt%, the Al of 2.44wt% 2 o 3 , 13.32wt% SiO 2 , 0.23% MgO, 5.53wt% F and 0.82wt% CaO) were added into 300g of the first hydrochloric acid with a molar concentration of 12mol / L, heated to 100°C and stirred and dissolved for 2 hours to obtain a mother liquor containing rare earth elements.

[0078] 2. Evaporation and impurity removal: Evaporate and concentrate the above-mentioned rare earth element-containing mother liquor at 70° C. to nearly dryness, add 400 g of hot water after cooling, stir and dissolve, and press filter to obtain the impurity-removed rare earth element-containing mother liquor.

[0079] 3. Extraction and impurity removal: adjust the pH value of the above-mentioned rare earth element-containing mother liquor after impurity removal to 3 with 1mol / L fourth hydrochloric acid, and add an organic extractant to extract three times (wherein the organic extractant and the rare eart...

Embodiment 3

[0085] Embodiment 3 is substantially the same as embodiment 1, and the difference is that the dissolving step of embodiment 3 is:

[0086] Dissolving: with 100g polishing powder waste material (the REO that contains 64.4wt%, the Al of 2.44wt% 2 o 3 , 13.32wt% SiO 2 , 0.23% MgO, 5.53wt% F and 0.82wt% CaO) were added into 250g of the first hydrochloric acid with a molar concentration of 9mol / L, heated to 90° C. and stirred and dissolved for 2 hours to obtain a mother liquor containing rare earth elements.

[0087] After testing, the rare earth oxide obtained in Example 3 contains 99.15wt% REO, 0.0017wt% Al, 0.0014wt% Si, 0.0020wt% Mg, 0.0011wt% F and 0.0025wt% Ca. The yield of rare earth oxide was 91.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com