Method for preparing disk-shaped MnO2 supercapacitor material with foamed nickel self-supporting nanosheet stack

A technology of supercapacitors and nanosheets, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of good reproducibility, high cycle stability, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

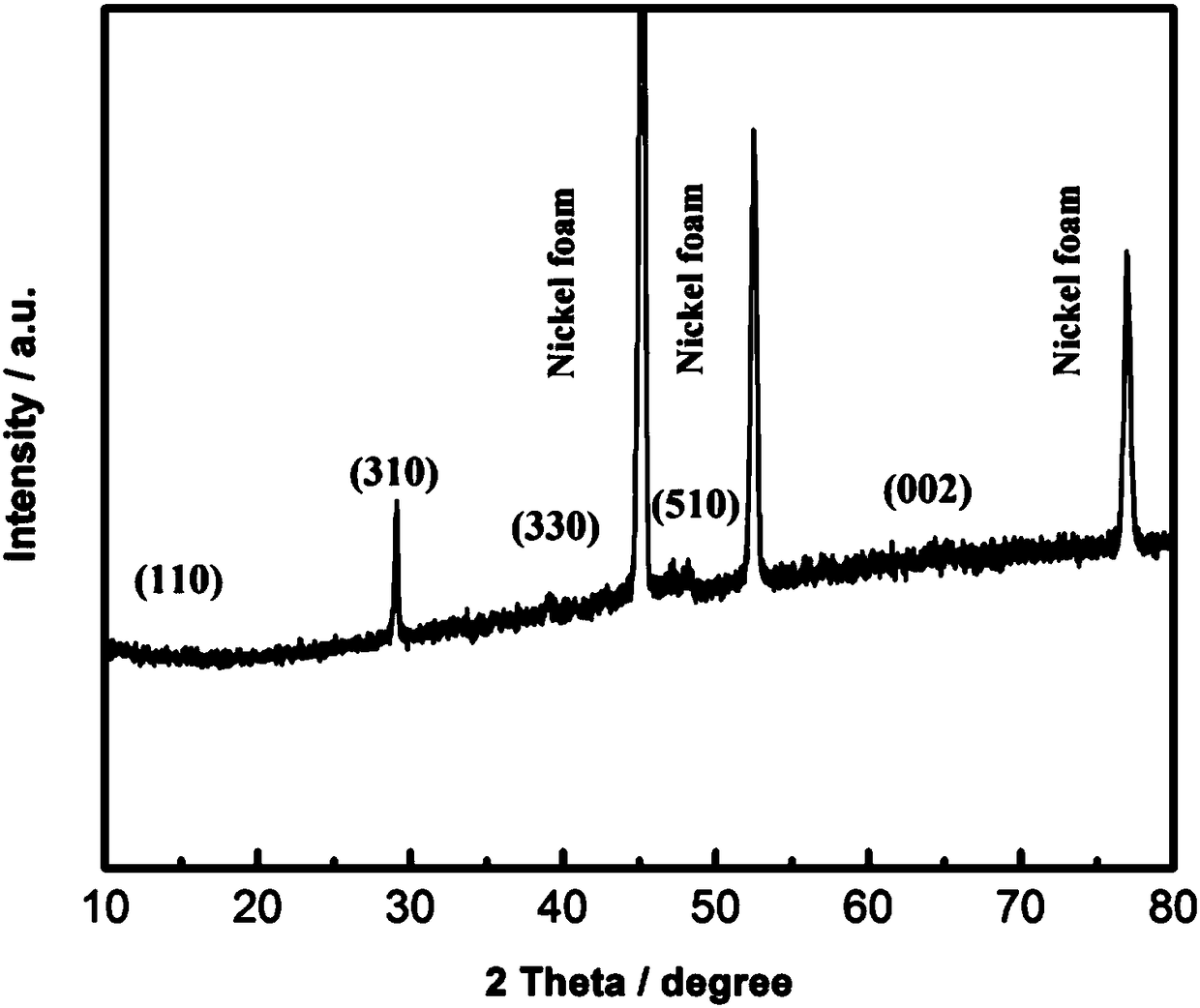

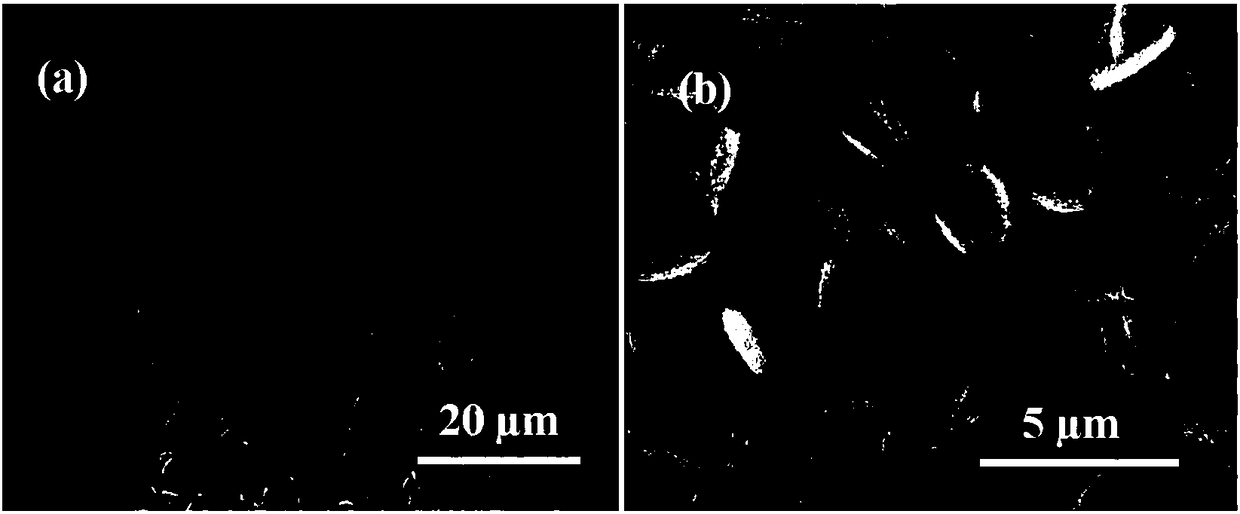

[0027] Example 1 Discoid MnO stacked with nickel foam self-supporting nanosheets 2 Preparation of electrode materials

[0028] In this embodiment, deionized water and ethanol are used to ultrasonically clean foamed nickel for 2 hours for pretreatment to remove surface impurities; manganese source, urea and ammonium fluoride are dissolved in deionized water, manganese source is manganese nitrate, manganese nitrate 0.15mol ·L -1 , Urea 0.15mol L -1 And ammonium fluoride 0.05mol L -1 , fully stirred to obtain a mixed reaction solution, then put the pretreated nickel foam into the reaction kettle, add the mixed reaction solution, and conduct a hydrothermal reaction at 130 ° C for 3 hours. After the reaction is completed and washed and dried, a nanosheet stacked discotic MnO 2 Precursor; discoidal MnO stacked with dried nanosheets 2 The precursor was placed in a muffle furnace and reacted at 350 °C for 2 h, and after cooling, the disc-shaped MnO with nanosheet stacks grown on ...

Embodiment 2

[0030] Embodiment 2 electrochemical performance test

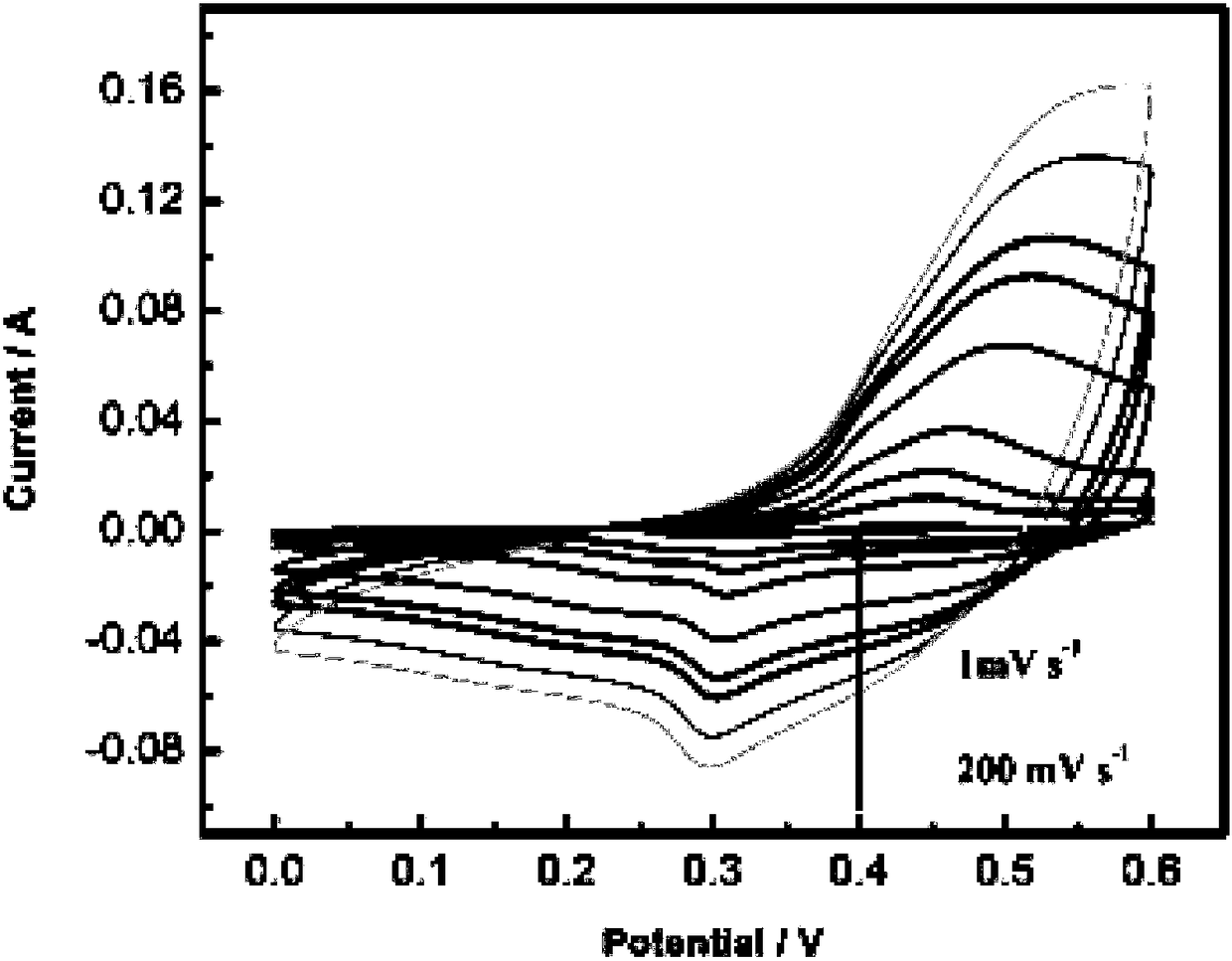

[0031] In this example, the disk-shaped MnO stacked with foamed nickel self-supporting nanosheets prepared in Example 1 2 Made into a supercapacitor electrode for electrochemical performance testing. Test results such as image 3 As shown, when the electrolyte concentration is 6mol·L -1 Discoid MnO with nickel foam self-supporting nanosheet stacks in aqueous KOH solution 2 The maximum specific capacity of the electrode can reach 1.37F cm -2 . Depend on Figure 4 It can be seen that after 4000 cycles, the Coulombic efficiency remains 100%, and the capacity retention rate is 91.2%.

[0032] Experiments show that the as-prepared Ni foam self-supported nanosheet stacked disk-like MnO 2 The maximum specific capacity of the electrode can reach 1.37F cm -2 , after 4000 cycles, the Coulombic efficiency remains 100%, and the capacity retention rate is 91.2%.

Embodiment 3

[0033] Example 3 Discoid MnO stacked with nickel foam self-supporting nanosheets 2 Preparation of electrode materials

[0034] In this example, deionized water and ethanol were used to ultrasonically clean the nickel foam for 3 hours to remove the surface impurities; the manganese source, urea and ammonium fluoride were dissolved in deionized water, the manganese source was manganese sulfate, manganese sulfate 0.12mol L -1 , Urea 0.12mol L -1 And ammonium fluoride 0.04mol L -1 , fully stirred to obtain a mixed reaction solution, then put the pretreated nickel foam into the reaction kettle, add the mixed reaction solution, and conduct a hydrothermal reaction at 120 ° C for 4 hours. After the reaction is completed and cleaned and dried, a nanosheet stacked discotic MnO 2 Precursor; discoidal MnO stacked with dried nanosheets 2 The precursor was placed in a muffle furnace and reacted at 400 °C for 2 hours, and after cooling, a disc-shaped MnO with nanosheet stacks grown on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com