Recycling method of fermented clostridium butyricum waste water, and fermented material and applications thereof

A technology of Clostridium butyricum and fermented waste water, which is applied in application, animal feed, animal feed, etc., to achieve the effects of improving survival rate, reducing feed-to-meat ratio, and reducing coliform rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

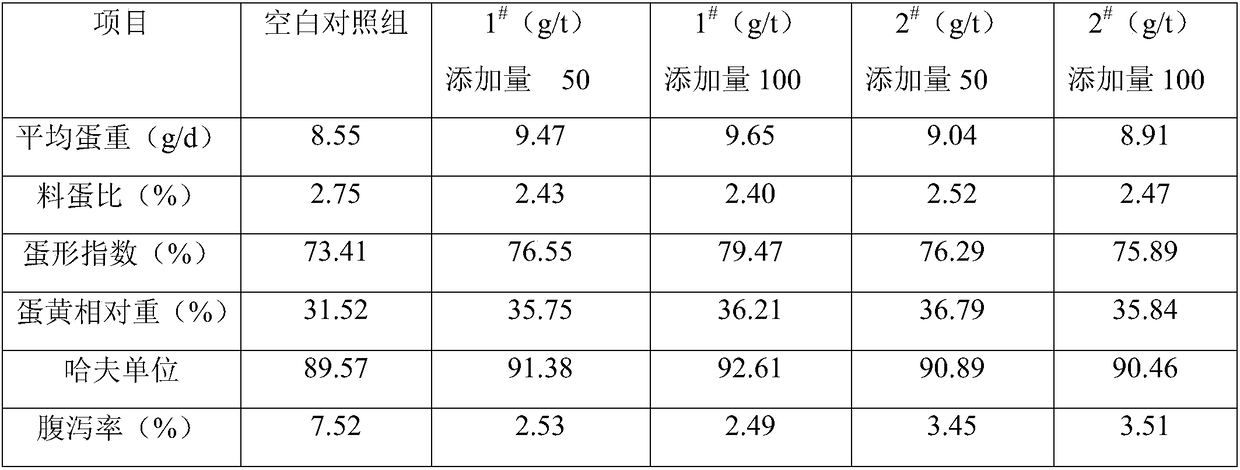

Examples

Embodiment 1

[0049] A method for reusing waste water fermented by clostridium butyricum, comprising the steps of:

[0050] Add 120kg of soybean meal powder, 120kg of corn flour, 240kg of rice husk powder, 190kg of corncob powder, and 50kg of calcium carbonate per ton of fermented wastewater.

[0051] The fermentation wastewater is the fermentation wastewater of the preserved strain Clostridium butyricum; the Clostridium butyricum is specifically LXKJYB-1, and the preservation number is: CCTCC M 2017485.

[0052] Its specific operation process is:

[0053] Mix soybean meal, corn flour, rice husk powder, corn cob powder, and calcium carbonate into the fermentation waste water tank and stir evenly to allow these solid substances to fully absorb the water, then put them into 25kg plastic bags, seal them and store them in the culture room The temperature is around 35°C for airtight fermentation;

[0054] The water content of the above-mentioned culture was 58.13%. During the cultivation proce...

Embodiment 2

[0061] A method for reusing waste water fermented by clostridium butyricum, comprising the steps of:

[0062] Increase the content of soybean cake powder and corn flour, the main nutrients in the culture, add 150kg of soybean meal, 180kg of corn flour, 220kg of rice husk powder, 190kg of corncob powder, and 40kg of calcium carbonate per ton of wastewater, and the secondary fermentation time is 24h and 48h respectively , 72h, 96h ambient temperature control at 35 ℃;

[0063] The fermentation wastewater is the fermentation wastewater of the preserved strain Clostridium butyricum; the Clostridium butyricum is specifically LXKJYB-1, and the preservation number is: CCTCC M 2017485.

[0064] Its specific operation process is:

[0065] Mix soybean meal, corn flour, rice husk powder, corn cob powder, and calcium carbonate into the fermentation waste water tank and stir evenly to allow these solid substances to fully absorb the water, then put them into 25kg plastic bags, seal them an...

Embodiment 3

[0073] A method for reusing waste water fermented by clostridium butyricum, comprising the steps of:

[0074] Add 250kg of soybean meal, 120kg of corn flour, 150kg of rice husk powder, 130kg of corn cob powder, and 80kg of calcium carbonate per ton of fermentation wastewater.

[0075] First, mix soybean meal, corn flour, rice husk powder, corncob powder, and calcium carbonate into the fermentation wastewater tank and stir evenly, so that these solid substances can fully absorb the water in them, then pack them into bags, seal them and ferment them at 35°C for 24h and 48h , 72h, 96h. The spore rate of Clostridium butyricum and Bacillus subtilis is measured by microscope observation, and the fermentation is terminated when the spore rate of Clostridium butyricum reaches 90-95%.

[0076] The fermentation wastewater is the fermentation wastewater of the preserved strain Clostridium butyricum; the Clostridium butyricum is specifically LXKJYB-1, and the preservation number is: CCTC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com