Anti-slip glass ice cup

A glass and ice cup technology, applied in glass forming, glass manufacturing equipment, glass reshaping, etc., can solve the problem of not being able to drink cold drinks in time, and achieve low-temperature thermal expansion coefficient, excellent mechanical shock resistance, and anti-skid effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

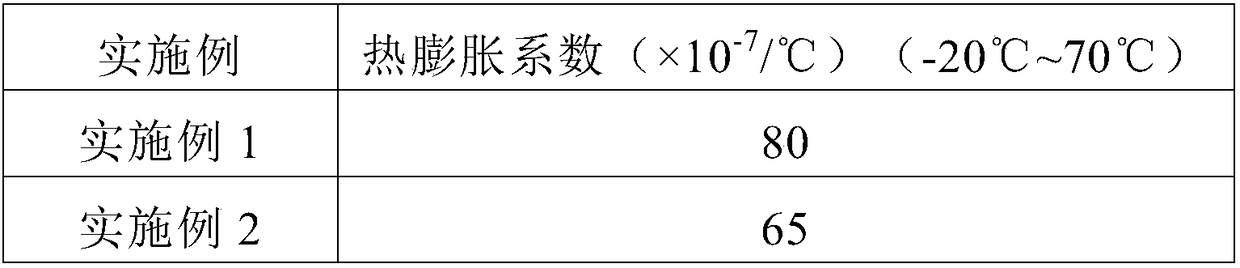

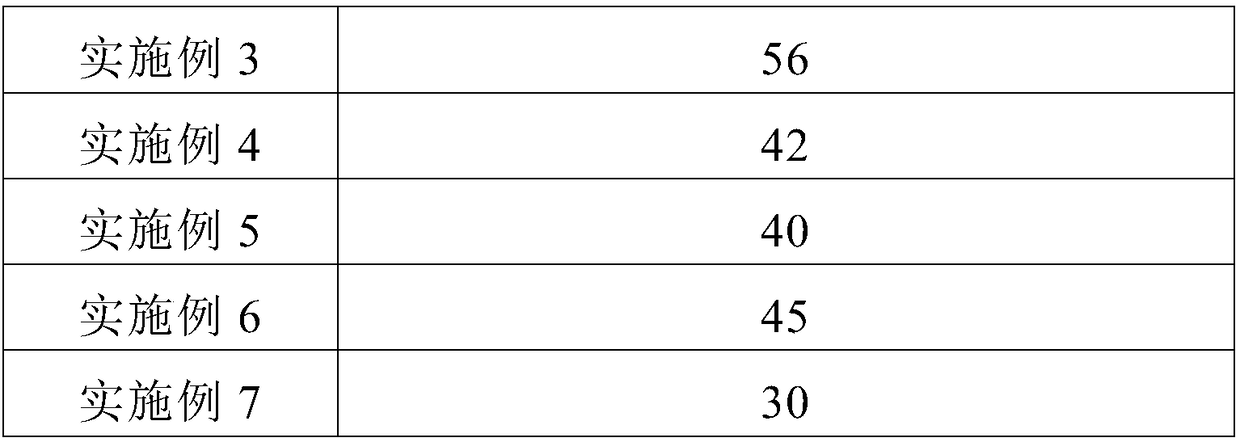

Embodiment 1

[0040] The non-slip glass ice cup consists of a glass water cup and a silicone sleeve. The glass water cup raw material (parts by weight): SiO 2 53.79 parts, Al 2 o 3 19.75 copies, B 2 o 3 8.24 parts, Na 2 O 1.37 parts, glass clarifier 1.35 parts. The glass clarifying agent is formed by mixing potassium nitrate and cerium dioxide at a mass ratio of 1:4.2.

[0041] Preparation method of non-slip glass ice cup:

[0042] S1 weighs raw materials by weight: SiO 2 53.79 parts, Al 2 o 3 19.75 copies, B2 o 3 8.24 parts, Na 2 1.37 parts of O, 1.35 parts of glass clarifier; all added to a planetary ball mill and ball-milled to a particle size of 5-20 μm to obtain a mixed powder; the glass clarifier is mixed with potassium nitrate and cerium oxide in a mass ratio of 1:4.2 .

[0043] S2 Add the mixture powder into a graphite crucible and heat it to 1530°C to melt it, and keep it at a stirring speed of 200 rpm and a temperature of 1530°C for 2 hours to fully carry out the...

Embodiment 2

[0047] The non-slip glass ice cup consists of a glass water cup and a silicone sleeve. The glass water cup raw material (parts by weight): SiO 2 53.79 parts, Al 2 o 3 19.75 parts, SrCO 3 15.38 copies, B 2 o 3 8.24 parts, Na 2 O 1.37 parts, glass clarifier 1.35 parts. The glass clarifying agent is formed by mixing potassium nitrate and cerium dioxide at a mass ratio of 1:4.2.

[0048] Preparation method of non-slip glass ice cup:

[0049] S1 weighs raw materials by weight: SiO 2 53.79 parts, Al 2 o 3 19.75 parts, SrCO 3 15.38 copies, B 2 o 3 8.24 parts, Na 2 1.37 parts of O, 1.35 parts of glass clarifier; all added to a planetary ball mill and ball-milled to a particle size of 5-20 μm to obtain a mixed powder; the glass clarifier is mixed with potassium nitrate and cerium oxide in a mass ratio of 1:4.2 .

[0050] S2 Add the mixture powder into a graphite crucible and heat it to 1530°C to melt it, and keep it at a stirring speed of 200 rpm and a temperatur...

Embodiment 3

[0054] The non-slip glass ice cup consists of a glass water cup and a silicone sleeve. The glass water cup raw material (parts by weight): SiO 2 53.79 parts, Al 2 o 3 19.75 parts, SrCO 3 15.38 copies, B 2 o 3 8.24 parts, Na 2 1.37 parts of O, 0.12 parts of fly ash, and 1.35 parts of glass clarifying agent. The glass clarifying agent is formed by mixing potassium nitrate and cerium dioxide at a mass ratio of 1:4.2.

[0055] Preparation method of non-slip glass ice cup:

[0056] S1 weighs raw materials by weight: SiO 2 53.79 parts, Al 2 o 3 19.75 parts, SrCO 3 15.38 copies, B 2 o 3 8.24 parts, Na 2 1.37 parts of O, 0.12 parts of fly ash, and 1.35 parts of glass clarifier; all added to a planetary ball mill and ball-milled to a particle size of 5 to 20 μm to obtain a mixed powder; the glass clarifier is potassium nitrate and cerium dioxide by mass ratio 1:4.2 mixed.

[0057] S2 Add the mixture powder into a graphite crucible and heat it to 1530°C to melt it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com