Stainless steel material and preparation method thereof

A stainless steel and duplex stainless steel technology, applied in the field of stainless steel materials, can solve the problems of high nickel price and human body metal allergy, and achieve the effects of less material removal, simplified processing technology and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

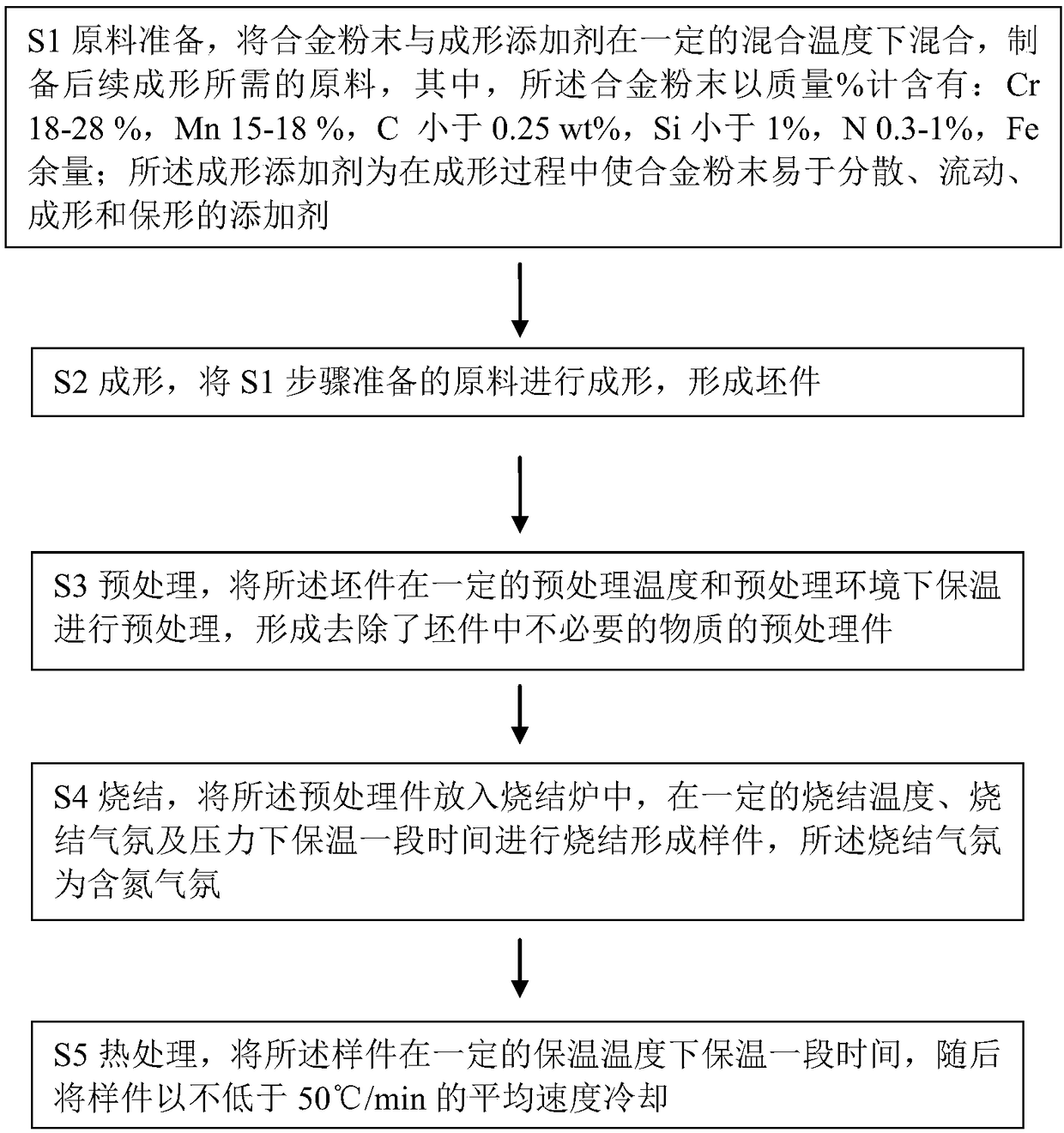

[0042] Such as figure 1 As shown, Embodiment 1 of the present invention provides a kind of preparation method of stainless steel material, specifically comprises the following steps:

[0043] S1 Raw material preparation, mixing alloy powder and forming additives at a certain mixing temperature to prepare the raw materials required for subsequent forming, wherein the alloy powder contains: Cr 18-28%, Mn 15-18%, C Less than 0.25%, Si is less than 1%, N 0.3-1%, and Fe balance; the forming additive is an additive that makes the alloy powder easy to disperse, flow, form and maintain shape during the forming process.

[0044] Compared with the traditional molten steel smelting, the embodiment of the present invention preferably adopts powder metallurgy to prepare the stainless steel material. The internal crystals of powder metallurgy are very uniform, the quality is consistent, and there is no segregation phenomenon. The stainless steel produced has reliable performance and uniform...

Embodiment 2

[0060] Embodiment 2 provides a kind of preparation method of stainless steel material, comprises the following steps:

[0061] S1 raw material preparation, the alloy composition is Cr 22wt%, Mn15wt%, C less than 0.12wt%, N0.5wt%, Si0.40%, Fe balance powder, and plastic, paraffin-based forming agent at 170-200 °C for 3 hours to obtain the raw materials required for injection molding.

[0062] S2 molding, pouring the raw materials prepared in step S1 into an injection molding machine, and inject molding at a temperature of 170-200° C. and a pressure of 20-100 MPa to obtain an injection molding blank.

[0063] S3 pretreatment, the blanks formed in step S2 are respectively kept in a vacuum environment at 200°C, 400°C, 600°C, and 1200°C for a sufficient time until the forming agent is completely released.

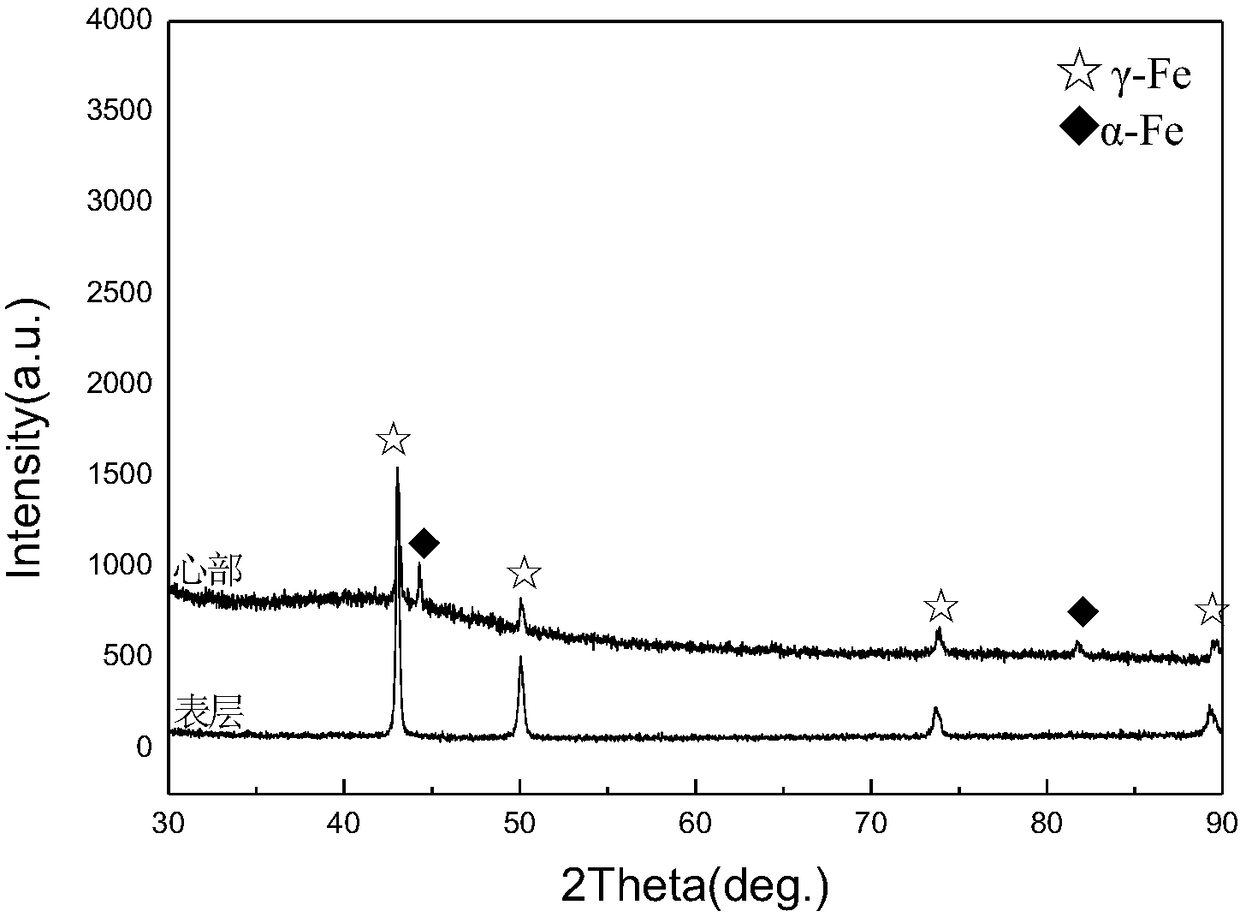

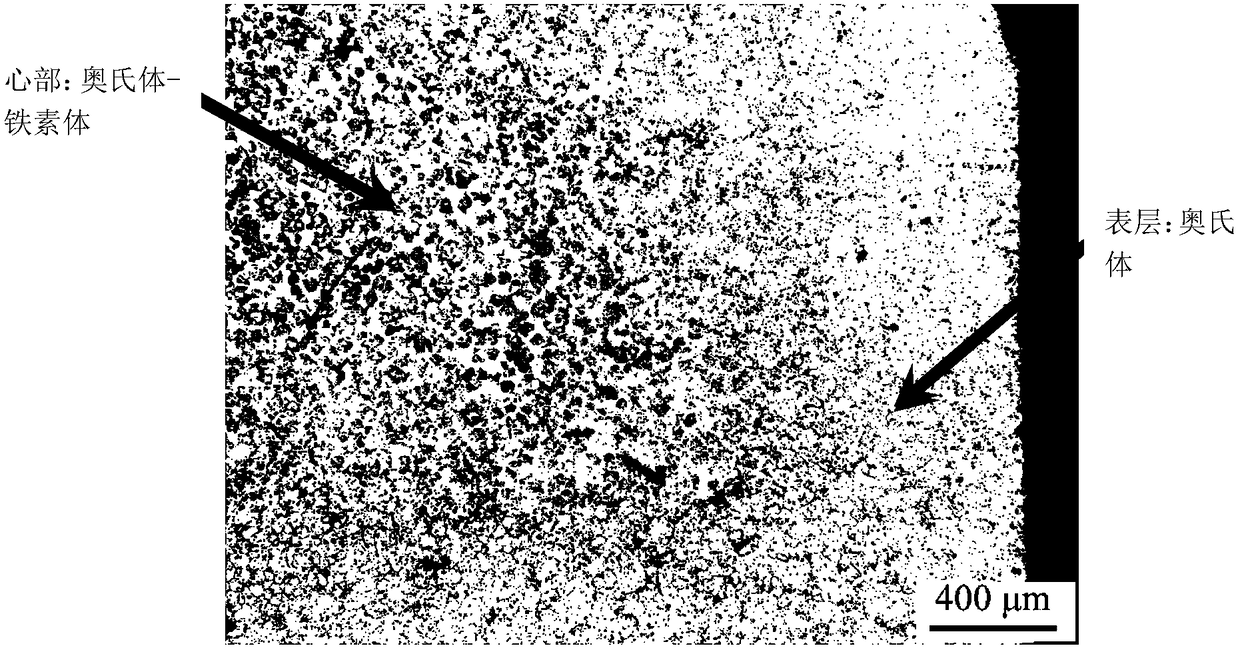

[0064] S4 sintering, put the pretreated piece obtained in step S3 into a sintering furnace to raise the temperature, and keep it at 1320°C and 0.05MPa pure nitrogen atmosphere ...

Embodiment 3

[0068] Embodiment 3 provides a kind of preparation method of stainless steel material, comprises the following steps:

[0069] S1 raw material preparation, the alloy composition is Cr 18wt%, Mn18wt%, C 0.16wt%, N 0.7wt%, Si1.0%, the rest of Fe powder, mixed with gasoline, paraffin-based forming agent at 30 ℃ for 0.5 Hours, the raw materials needed for compression molding are obtained.

[0070] S2 forming, pouring the raw materials prepared in step S1 into a mold, molding at a temperature of 0-30°C and a pressure of 20-500MPa to obtain a molded blank.

[0071] S3 pretreatment, put the blank formed in step S2 at 600°C in a mixed gas of nitrogen and hydrogen, and keep it warm for a sufficient time until the forming agent is completely released.

[0072] S4 sintering, put the pretreated piece obtained in step S3 into a sintering furnace to raise the temperature, and keep it warm for 60 minutes at 1400°C under a mixed atmosphere of 0.05MPa nitrogen and hydrogen.

[0073] S5 heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com